5 Industrial Uses That Benefit from Prismatic Reflective Tape

What Are the Top 5 Industrial Uses for Prismatic Reflective Tape?

Every day, railroad workers perform maintenance in dark tunnels, maritime employees perform challenging search-and-rescue operations, and truck drivers transport materials throughout the United States. Yet no matter the scenario, it is imperative that hazards are quickly and easily spotted from a safe distance—especially in environments regulated by the Occupational Safety and Health Administration (OSHA), where clear visual communication is essential for maintaining compliance and preventing injury.

Prismatic reflective tape can help achieve those goals. This high-performance reflective safety tape is used across a wide range of industries to make important messages visible from greater distances than standard-grade materials. The top five industrial uses include:

- Transportation and Work Zone Safety

- Rail Safety

- Maritime Industries

- Mines and Mining-Related Activities

- Safety Signs and Labels for Low-light Settings

From boosting visibility on highways to guiding emergency crews through smoke-filled ship corridors, prismatic tape plays a vital role in daily safety operations. The following scenarios provide a more comprehensive view on how industrial teams rely on this high visibility tape to meet regulations, prevent accidents, and protect workers in demanding environments.

1. Transportation and Work Zone Safety

The United States Department of Transportation (USDOT) and the Federal Motor Carrier Safety Administration (FMCSA) set regulations for commercial vehicles and roadway safety. To stay compliant and protect both drivers and the public, many companies use reflective safety tape on trucks, trailers, and work zone devices.

Prismatic tape, a type of high visibility tape, plays a crucial role in meeting these standards. It helps companies:

- Apply DOT-compliant labels to fleet vehicles

- Meet FMCSA requirements (49 CFR 393.11) for red-and-white reflective material on the rear and sides of trailers and tankers

- Improve road safety with custom messaging like “Stay Back,” “Wide Load,” or “Wide Right Turn”

- Mark emergency equipment, such as fire extinguishers, with reflective labels for quick identification

In work zones, reflective tape enhances visibility for:

- Traffic cones, barrels, and barricades

- Signs, barriers, and other traffic control devices used by contractors and municipalities

By enhancing vehicle visibility and marking high-risk zones, prismatic reflective tape helps companies meet federal safety standards while protecting both workers and the public.

2. Rail Safety

Trains operate around the clock and often travel through tunnels or other low-light conditions. Prismatic reflective tape improves visibility and safety in these high-risk environments.

Key uses include:

- Labeling switch controls and trackside equipment to keep them visible in dark or obstructed conditions

- Meeting Federal Railroad Administration (FRA) retroreflective marking requirements (49 CFR 224.106)— reflective materials must be applied at both ends of every railcar and every 12 feet along the side

- Printing railyard safety signage that remains readable in poor lighting or bad weather

For an industry that operates around the clock and across varied conditions, reflective labeling is a vital component of operational safety and FRA compliance.

3. Maritime Industries

The United States Coast Guard (USCG) requires reflective tape on all lifesaving devices—including lifeboats, rafts, buoys, and lifejackets—to improve visibility during nighttime rescue operations and in rough weather.

Prismatic tape supports maritime safety by:

-

Helping facilities comply with USCG requirements for lifesaving equipment

-

Enhancing wayfinding through tight, low-lit ship corridors

-

Identifying hazards and improving visibility of equipment on ships, in shipyards, and aboard oil rigs

-

Assisting with search-and-rescue efforts in dark or stormy conditions

Whether at sea or in the shipyard, prismatic tape supports lifesaving visibility and keeps critical equipment easy to locate in unpredictable environments.

4. Mines and Mining-Related Activities

In mining and resource extraction, low-light conditions and airborne dust can create dangerous situations. High visibility tape helps mitigate these risks by increasing awareness and guiding workers to safety.

Use cases include:

-

Marking vehicles and machinery to highlight moving parts and improve visibility underground

-

Outfitting escape paths with durable lifelines marked every 25 feet, in accordance with Mine Safety and Health Administration's (MSHA) 30 CFR 75.380 standard

- Creating OSHA-compliant floor marking and safety signs that direct workers, highlight emergency equipment, and reinforce safety protocols

With increased visibility in dark, dusty settings, high visibility tape strengthens miner safety and supports compliance with MSHA regulations.

5. Safety Signs and Labels for Low-Light Settings

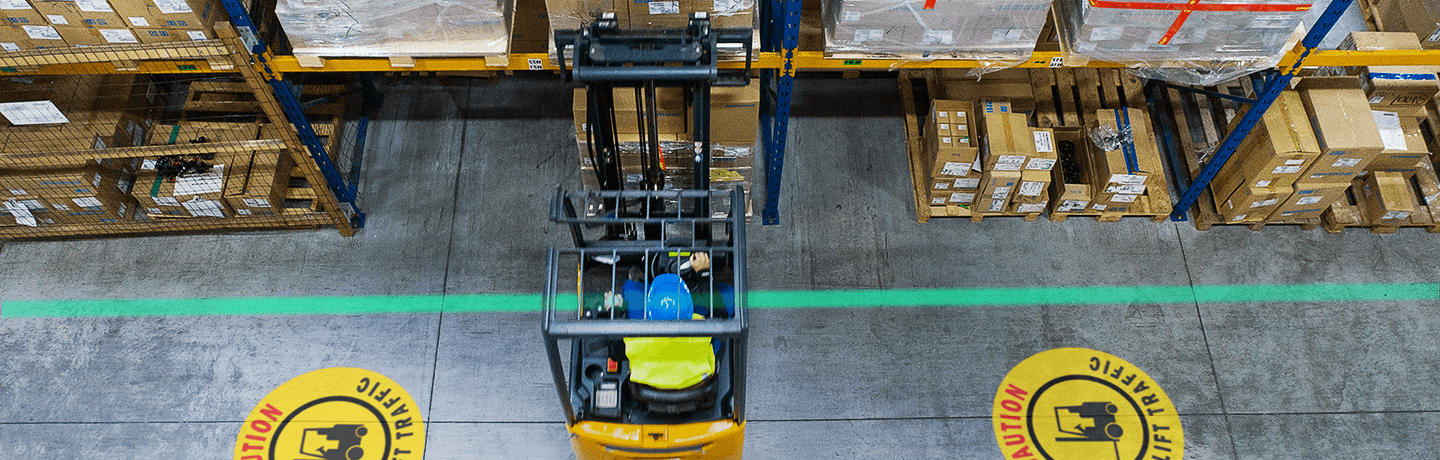

In industrial facilities, warehouses, or emergency situations, reflective safety tape supports clear communication and fast response in poor lighting conditions.

With DuraLabel® Sign and Label Supplies and the all-in-one DuraLabel Toro® Max Industrial Sign and Label System, teams can create durable custom labels on prismatic tape for:

-

Arc flash labels that remain visible before maintenance or exposure

-

Custom safety signs that meet regulations and stay legible in all lighting conditions

-

Warehouse wayfinding to guide personnel during outages or restricted visibility

-

Perimeter fence labels that deliver hazard warnings or directional messaging

-

Emergency signage that directs first responders to exits, stairwells, or safety equipment

When lighting is unreliable or visibility is limited, reflective safety tape ensures that hazard warnings and navigation signage remain clear and easy to follow.

Honorable Mention: Emergency Response and Facility Egress

While not one of the top five applications, emergency response labeling is another critical use for prismatic reflective tape—especially in facilities where power outages, low lighting, or complex layouts pose safety risks. In these situations, reflective messages help guide first responders and personnel to exits, equipment, and safe zones with speed and clarity.

Custom labels printed on high visibility tape can be applied to:

-

Exit signage and egress routes

-

Fire extinguishers and emergency shutoffs

-

First aid stations and safety equipment

-

Electrical panels and restricted access points

In addition, reflective safety tape can complement OSHA compliant floor marking systems by increasing visibility along evacuation paths, stairwells, and high-traffic zones—especially when traditional floor markings may be obscured in dark or dusty environments.

When seconds matter, clear visual guidance backed by durable, reflective materials can help save lives.

DuraLabel Reflective Tape Solutions for Improved Visual Communication

A safer facility starts with labels that stand out—even in the toughest conditions. DuraLabel provides the tools and materials you need to create high-visibility messaging that supports safety, compliance, and efficiency across your operations.

DuraLabel’s Prismatic Reflective Tape is built for performance in demanding environments. This reflective tape delivers superior brightness and long-lasting adhesion, making it ideal for transportation, rail, marine, mining, and low-light applications. It resists abrasion, moisture, and harsh weather—so your safety messages stay visible when it matters most.

The DuraLabel Toro Max Industrial Sign and Label System gives teams the power to print custom labels directly onto prismatic reflective tape—on-site and on demand. Its intuitive touchscreen interface and built-in software eliminate the need for a computer, making it easy to design and print compliant, high-visibility labels wherever work is happening. Whether you're in a railyard, on a jobsite, or aboard a vessel, Toro Max ensures your critical messages are clear, durable, and ready when you need them.

Want to improve visibility and safety across your facility? Download the OSHA Signage Quick Start Guide or call 1-888-411-3520 to speak with a labeling expert.

Read Next:

Why Tough Mechanical Environments Require Durable Labels

DuraLabel’s Tough-Tested Process: Raising the Bar for Label Durability

Related Resources

Reflective Floor Tape: Illuminating Safety

There are a lot of different hazards in the modern workplace. Between moving parts, vehicle traffic, ledges, ...

Read

Shine a Light on Safety: LED Floor Marking Improves Wayfinding

Floor marking and signs in industrial environments are a cost-effective way to increase safety compliance, ...

Read

Upgrade Warehouse Traffic Safety with Floor Marking

Modern warehouses experience a wide variety of traffic ranging from forklifts and pedestrians to large ...

Read.png)