Why Tough Mechanical Environments Require Durable Materials for Tags

Why Do Industrial Labels Need to Be Durable?

Industrial labels need to be durable because harsh conditions can quickly degrade materials. Exposure to heat, chemicals, and abrasion can cause label adhesives to fail, text to fade or discolor, and be the visual message to become illegible. When this happens, safety warning and equipment IDs are lost, which can trigger compliance issues, slow operations, and raise accident risks.

Unlike normal adhesive stickers, industrial labels are expected to survive where equipment runs hot, chemicals splash, parts scrape, and weather hits hard. If a label cannot stay attached and legible, it cannot do its job. Durable materials keep critical information visible so workers can identify hazards, follow procedures, and maintain equipment without guessing.

Mechanical sites expose labels to predictable stress points that cause failure fast. The next step is understanding what those conditions look like on the ground, and how each one affects label performance.

The sections below break down what causes label failure on mechanical sites and how to choose materials that hold up.

-

What Causes Industrial Labels to Fail on Mechanical Sites?

-

Which Durable Label Materials Work Best for Heat, Chemicals, and Abrasion?

-

How Do You Choose the Right Label for Mechanical Equipment?

-

What OSHA Sign Requirements Apply to Mechanical Site Labels?

-

Resources and Next Steps

Labeling Challenges in Harsh Environments

- Extreme Temperatures: Machinery, foundries, and engine components can reach high temperatures, causing standard labels to melt, char, or lose adhesion.

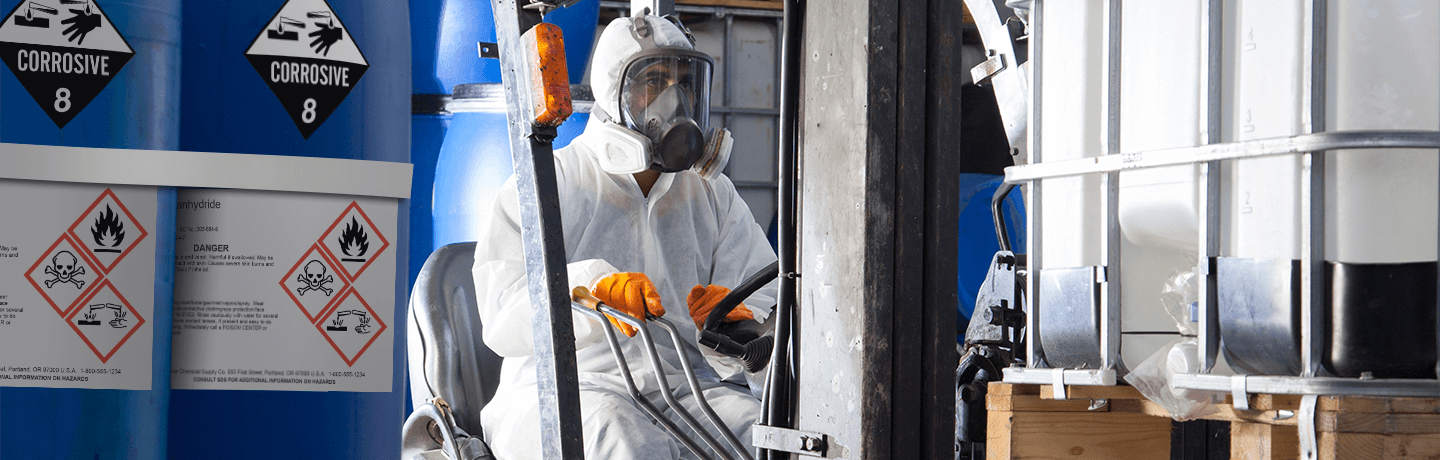

- Chemical Exposure: Harsh solvents, fuels, and industrial cleaners can break down adhesives and fade printed text, making labels unreadable.

- Weather & UV Damage: Outdoor labels are subject to rain, snow, direct sunlight, and extreme temperature fluctuations, leading to cracking, peeling, and fading.

- Abrasion & Impact: Heavy-duty equipment, moving parts, and frequent handling can wear down labels, causing them to become illegible.

- Surface Challenges: Rough, oily, or uneven industrial surfaces make adhesion difficult, leading to label failure.

To ensure operational efficiency and safety, businesses must select high-performance label stock that withstands harsh conditions and supports regulatory compliance.

Regulatory Compliance and Industry Standards for Durable Labels

OSHA and ANSI Labeling Standards

In busy industrial environments, small miscommunications can have serious consequences. A missing label or unclear message can slow down repairs or lead to safety incidents. That’s why clear, durable labeling is more than a requirement—it's a key part of workplace safety.

Standards from the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) are designed to simplify communication. OSHA focuses on labels that are legible and long-lasting, even in tough environments. ANSI adds consistency through standardized color coding, helping workers recognize hazards and important information.

When facilities follow these standards, labeling becomes a tool for safety, efficiency, and better communication.

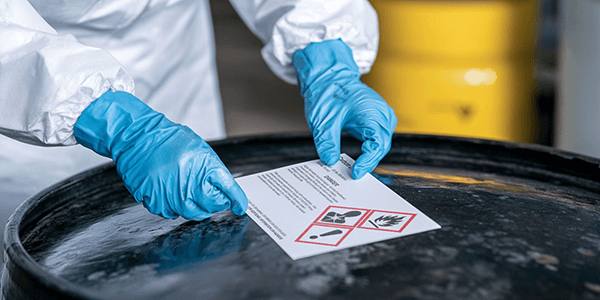

GHS-Compliant Hazardous Chemical Labeling

Chemical labeling requires instant recognition. The Globally Harmonized System (GHS) provides a standardized way to present critical information using pictograms, signal words, and hazard statements that can be understood across languages and industries.

To stay compliant with both OSHA’s Hazard Communication Standard (HCS) and GHS, facilities must use durable label stock that holds up to chemical exposure, moisture, and abrasion. In this case, durability plays a direct role in keeping people safe and informed.

Pipe and Electrical Labeling Standards

Labeling systems aren’t just about organization—they’re about making the right information easy to see in the moment it’s needed. A color-coded pipe label or a clear electrical hazard sign can guide safe decisions on the floor.

ANSI/ASME A13.1 sets standards for pipe marker color and placement, while NFPA 70E outlines requirements for electrical labels that remain visible in extreme conditions. These systems give workers what they need to respond quickly and safely.

How to Choose the Best Label Stock for Tough Environments

1. High-Temperature Label Stock: Engineered for Extreme Heat

Industries such as metal fabrication, automotive manufacturing, and aerospace require labels that endure prolonged exposure to extreme heat without fading, warping, or peeling. Selecting the right label supplies is key to ensuring durability in tough environments. Below are some of the most reliable options for high-temperature industrial applications.

Labeling for Heat-Intensive Environments:

- High-Temp Poly Label Stock: A flexible, durable material that resists cracking, peeling, and discoloration, making it ideal for labeling machinery like furnaces, boilers, motors, and engines. This supply can withstand temperatures up to 302°F.

- High-Temp Tag Stock: A tear-resistant material designed for tagging projects in high-heat environments such as food processing plants, power stations, and metal fabrication facilities, withstanding temperatures up to 446°F.

2. Industrial Pipe Labels: Ensuring Compliance and Visibility

Pipelines carrying hazardous chemicals, gases, or high-pressure steam require clear labels that remain intact despite extreme moisture and temperature fluctuations. These labels are essential for regulatory compliance, workplace safety, and maintenance efficiency. Selecting the appropriate pipe marking labels is critical for ensuring long-term visibility and adherence to safety standards.

Pipe Marking Labeling Solutions:

- Pipe Marking Labels: Engineered to withstand harsh industrial conditions, these labels support compliance with ANSI/ASME A13.1 and IIAR 2-2021 standards for clear communication and operational safety.

- High-Temperature Recirculated Liquid Ammonia Pipe Markers: Specifically designed to endure extreme temperatures and ammonia exposure, these pipe markers help improve hazard identification and protect employees from dangerous ammonia leaks.

3. Custom Safety Labels: Resistant to Chemicals and Abrasion

Workplaces dealing with hazardous materials, corrosive chemicals, or frequent exposure to industrial cleaners need labels that resist fading and degradation. These labels are critical for warning signs, safety instructions, and compliance markings. To meet these demands, consider the following chemical—and abrasion—resistant labeling options.

Recommended Label Stock for Harsh Chemical Environments:

- Chemical-Resistant Label Stock: Built to withstand exposure to strong solvents and harsh chemicals, making it ideal for food processing, manufacturing, automotive, and oil industries.

- GHS Labels: Compliant with the HCS, these labels resist moisture, abrasion, chemicals, UV light, and temperature, making them suitable for hazardous material identification in industrial environments.

4. Durable Labels for Outdoor Environments: Built to Withstand the Elements

Outdoor equipment, electrical boxes, and industrial signage must remain readable despite prolonged exposure to harsh weather conditions. Durable outdoor labels, like DuraLabel’s Outdoor Blank Die-Cut Labels, are designed to resist UV rays, rain, snow, and fluctuating temperatures. For long-term outdoor performance, the following materials offer weather-resistant durability and enhanced visibility.

Outdoor-Ready Label Stock:

- Premium Vinyl Label Stock: Suitable for indoor and outdoor use, premium vinyl labels hold strong across various surfaces and temperatures. It resists UV light, moisture, and most chemicals, keeping labels intact and legible in diverse work environments.

- Reflective Vinyl Label Stock: Enhances visibility in low-light environments, such as underground facilities or poorly lit work areas, ensuring safety and compliance.

5. Harsh Environment Label Stock: Impact-Resistant Solutions for Heavy Equipment

Industrial machinery, forklifts, and mining equipment require labels that remain securely in place despite continuous vibration, impact, and exposure to grease and dust. For rugged applications where standard adhesives fail, the following label stocks deliver strong adhesion and lasting durability.

Heavy-Duty Label Stock:

- High-Tack Label Stock: Designed for challenging surfaces, this high-tack adhesive ensures labels stay firmly in place, maintaining legibility and adhesion in demanding environments.

- Ultra-Aggressive Adhesive Vinyl Label Stock: Featuring an extra-strong adhesive, this option is ideal for surfaces that are difficult to label, ensuring long-lasting durability and reliability.

Industrial-Grade Labeling for Tough Environments

Industrial facilities must choose the right label materials to maintain safety, compliance, and efficiency. With durable labeling solutions, businesses can confidently mark equipment, pipelines, and hazardous areas with labels designed to withstand heat, chemicals, moisture, and abrasion—ensuring long-lasting visibility and reliability in any condition.

Customization and Printing Options for Industrial Labels

Printing industrial labels in-house gives companies greater flexibility, reduces costs, and allows for customization based on specific workplace hazards. On-demand printing minimizes downtime by enabling teams to produce labels as needed—eliminating the wait for third-party suppliers.

In-house labeling also allows companies to tailor labels for specific hazards, instructions, barcodes, or compliance needs. This approach reduces waste, avoids bulk order expenses, and supports fast, efficient updates across changing environments.

In-house labeling also allows companies to tailor labels for specific hazards, instructions, barcodes, or compliance needs. This approach reduces waste, avoids bulk order expenses, and supports fast, efficient updates across changing environments.

To support these needs, businesses can turn to reliable, industrial-grade sign and label systems designed for durability and ease of use.

DuraLabel Sign and Label Solutions

An industrial sign and label system allows businesses to produce durable, high-quality labels that withstand extreme conditions. DuraLabel’s Toro Max Industrial Sign and Label System is a portable, all-in-one thermal transfer printer built for efficiency and reliability. Its intuitive touchscreen and rugged design make it easy to create compliant safety signs, hazard labels, and equipment markers—right where they’re needed.

With durable in-house labeling solutions, businesses can streamline operations, stay compliant, and produce professional-grade labels customized to their environment.

DuraLabel Labeling Tools for Tough Mechanical Environments

Durable labeling is essential for workplace safety, compliance, and operational efficiency. By choosing high-performance label stock, businesses can ensure that safety signs, equipment labels, and hazard markers remain legible and intact, even in the harshest environments.

For companies ready to enhance their labeling strategy, DuraLabel’s Toro Max Industrial Sign and Label System Start Kit provides a professional-grade solution for producing long-lasting, compliant labels on demand. Investing in high-quality labels not only improves workplace organization but also strengthens safety communication—keeping teams productive and protected.

Want to ensure your facility meets regulatory requirements? Download the free OSHA Signage Quick Start Guide for expert insights on compliance and best practices.

For personalized assistance in selecting the right labeling solution, call 1-888-786-9223 to speak with a dedicated safety representative today.

Read Next:

Top 5 Challenges Mechanical Project Managers Face

Keep Job Sites Safe: How Custom Labels Change the Game for Contractors

Related Resources

Why Worksites Need an Outdoor Label Printer for Extreme Environments

How Can Labels Stay OSHA-Compliant in Harsh Environments? Labeling for extreme environments while maintaining ...

Read

Why Custom Industrial Labels Matter for Mechanical Job Sites

How Do Custom Industrial Labels Improve Safety and Organization on Job Sites? Mechanical job sites are ...

Read

HMIS Labeling and How the HMIS Labeling System Works

How Does the HMIS Labeling System Work? The Hazardous Materials Identification System (HMIS)uses color bars ...

Read.png)