How Sun Exposure Affects Pipe Labels

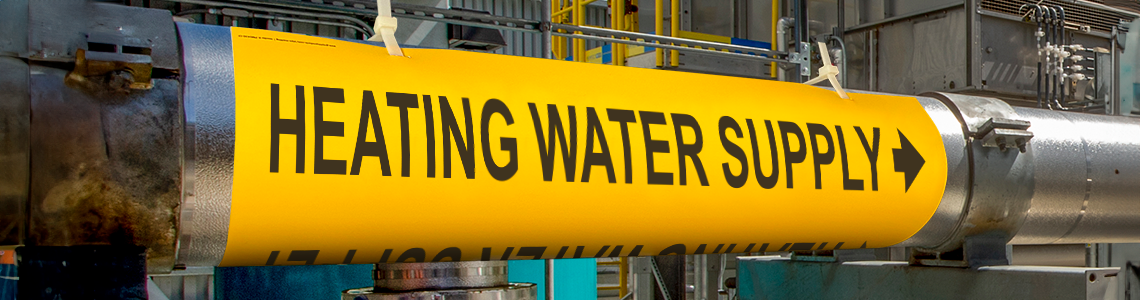

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and compressed air, which is crucial to many applications. The diverse materials used to create these pipes make them a powerful and indispensable tools for maintaining daily operations for industries like manufacturing, energy production, and chemical processing. While rugged pipes are essential, resilient pipe labels are nearly as important. These pipe markers are tough, resilient, and stand the test of time - essential features in a tool that not only guides workers, but saves lives.

The 5 Main Types of Pipe Materials That Can Benefit from Pipe Labels

- Copper - Copper is used for hot and cold water transportation and is mainly used in the refrigeration industry due to its long-lasting properties. These pipes are resistant to UV sun exposure and can last up to 60-70 years.

- Galvanized steel - Utilized as a water and sewer supply line material. Many industries, such as oil and gas, prefer this type of pipe due to its durability, strength, and resistance to high pressure. These pipes are immune to UV sun exposure.

- Polyvinyl chloride (PVC) - Used in applications across various industries including, healthcare and automotive. PVC pipes are designed to be strong, lightweight, flexible, and easy to handle. Along with all these qualities, PVC is resistant to corrosion and tends to last decades before needing to be replaced. These pipes are not designed to be in direct sunlight for extended periods as it shortens their life expectancy. Easily damaged by UV sun exposure, they are only suitable for indoor use. It is one of many types of plastic that have been flagged for contamination caused by thermal degradation.

- Acrylonitrile butadiene styrene (ABS) - A common thermoplastic used to make light, rigid, molded products such as pipe and automotive body parts. Similar to PVC pipes, ABS pipes are ideal for industrial applications to drain, waste, and vent piping systems and as insulation for electrical cables. It's best when used outside, underground, in the extreme cold, and where it isn't in direct sunlight, which is why plumbers prefer them.

- Cross-linked polyethylene (PEX) - PEX pipes are most commonly used for applications involving hot and cold potable water delivery, wastewater handling, agricultural irrigation, electrical wiring, cable insulation, and more. Due to its electrical and mechanical properties, the wire cables industry predominantly utilizes this material because of its insulated protection to electrical wiring. The insulation is resistant to weather, heat, and moisture, allowing the wires to provide energy safely.

Can Ultraviolet Sun Exposure Affect Pipes and Their Pipe Labels?

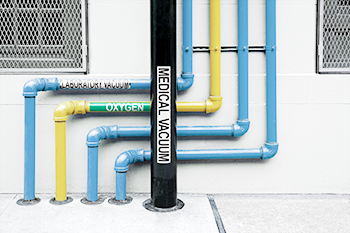

Pipes can endanger the lives of workers if they do not have proper pipe identification labels. Pipe labels provide essential information where it's needed, ensuring the safety of those it affects the most. Implementing a pipe labeling system can benefit various facilities to support safety programs.

Although the Occupational Safety and Health Administration (OSHA) does not require pipe markers, they recommend following the American National Standards Institute (ANSI) standards, which offer some general guidelines for creating pipe labeling systems that can ensure safety in your facility.

Prolonged ultraviolet (UV) sun exposure can affect some materials used to create pipes. Here’s a list of the most common pipes and how UV exposure affects them:

- Galvanized steel pipes - Immune to UV sun exposure.

- PVC pipes - PVC can experience degradation resulting from exposure to ultraviolet radiation, such as stiffness, pressure capacity, strength, or modulus. To limit the effects of UV on PVC pipe, an inhibitive additive is included in the material formulation.

- Copper pipes - UV rays have zero effect on the integrity of the material.

- PEX pipes - Easily damaged by UV sun exposure and are only suitable for indoor use. It is one of many types of plastic listed for contamination caused by thermal degradation.

- ABS pipes— Similar to PVC, these pipes can be exposed to UV rays, but they are not advised for prolonged outdoor exposure for more than a couple of years.

If prolonged sun exposure can damage industrial pipes, pipe labels are also not immune to UV sun exposure. Many pipe markers are made using premium vinyl, a synthetic polymer made from ethylene and chlorine, the same material used to create PVC. People use vinyl because of how durable the material is, and the variety of surfaces it can be used on.

Unfortunately, vinyl pipe markers are not immune to UV sun exposure. When the sun interacts with the vinyl pipe label, over time it weakens the chemical bonds that hold the material together, creating a process called photodegradation, which causes the material to become brittle, crack, or discolor.

The time it takes for the pipe label to break down is dependent on several factors:

- The intensity and duration of the UV exposure

- The thickness and composition of the vinyl

- The presence of any protective coatings or additives

However, there are reliable pipe labels that can better withstand these tough conditions.

DuraLabel Resources for Pipe Labels

As we have come to find, not all materials are immune to UV radiation. Prolonged sun exposure weakens many materials over time. Still, there are ways to slow down the process, such as UV inhibitors that protect the pipe identification labels from the harmful effects of UV radiation.

The average lifespan of premium vinyl pipe labels exposed to frequent UV rays is 3-5 years before they should be considered for replacement. DuraLabel’s extended-life vinyl tape is designed to last beyond the average lifecycle and not need replacement for at least eight years. It works on a variety of indoor and outdoor pipe labeling surfaces.

The flexible material is ideal for manufacturing operations to mark equipment, pipes, chemical containers, and outdoor surfaces. DuraLabel’s pipe label printer—the DuraLabel Toro Max Industrial Sign and Label Print System — uses materials that have been tough tested to withstand a multitude of environmental elements, including ultraviolet radiation. Get help crafting a system that will provide the visual communication you need. Call 1-888-902-4890, and one of our experts will guide you through the process.

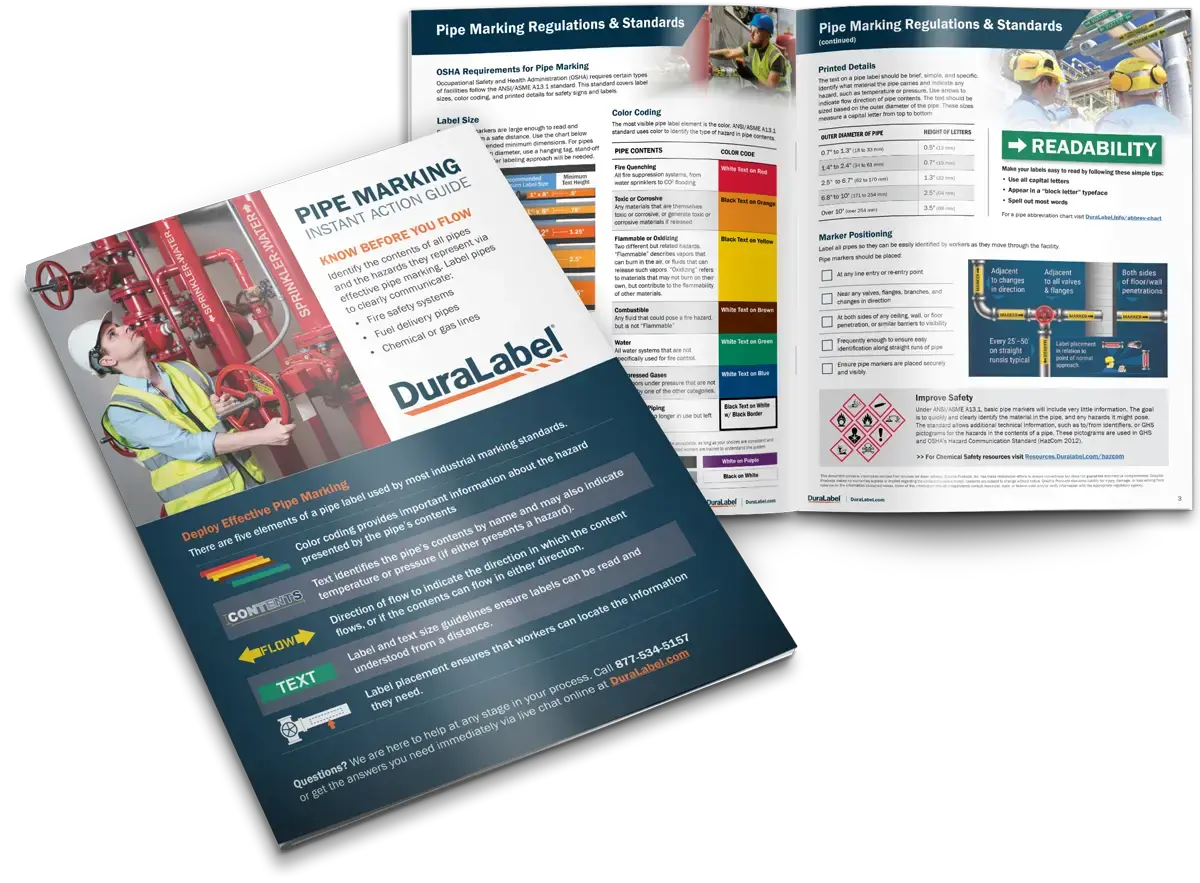

DuraLabel’s free Pipe Marking Instant Action Guide provides a pipe marking color guide and identifies industry-specific requirements and standards. Download a copy of the Pipe Marking Quick Start Guide today.

Learn more about pipe labeling with the free Instant Pipe Marking Safety Compliance Chart. It provides quick reference to necessary pipe labeling information, such as ANSI/ASME standards, where to place the labels, and other important content about the labels.

Read Next:

DuraLabel’s Tough-Tested Process: Raising the Bar for Label Durability

Pipe Marking and Pipe Corrosion Control

Related Resources

Don’t Just Label It—Build a Pipe Marking Plan That Works

Why is Pipe Marking Critical for Safety and Compliance? In industrial environments, whether dealing with ...

Read

Safety that Sticks: Using Pipe Labels for Every Size and Type of Pipe

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational ...

Read

Pipe Marking Basics: OSHA and ANSI/ASME Labeling Standards

Why Is Pipe Labeling Important for Facility Safety and Efficiency? Pipes can put people and facilities in ...

Read.png)