Safety that Sticks: Using Pipe Labels for Every Size and Type of Pipe

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational efficiency. Stocking the correct sizes, shapes, and styles of pipe labels for different types and sizes of pipes poses a significant challenge. From small-capacity water and gas lines to massive treatment and chemical pipes, you need the right tools to make sure all pipes are accurately and effectively labeled. There is no one-size-fits-all solution. Particularly when you consider materials, environment, and application for each unique facility.

One Size Does Not Fit All for Pipe Labels

Whether your facility has a small chemical installation or a vast, multi-stage industrial process, there are dozens of different sizes, shapes, and materials of tubes, pipes, and fixtures that will require pipe marking labels. Here are some important considerations when creating a pipe marking plan for your facility:

Variety in Pipe Materials: Pipes can be made from a wide range of materials, including metals (steel, copper, aluminum), plastics (PVC, CPVC, HDPE), and composites. Each material presents unique challenges in terms of label adhesion, durability, and visibility.

- Metal Pipes: Pipe labels may not adhere well to rough or oily surfaces.

- Plastic Pipes: Certain adhesives might not bond effectively, especially on low-energy surfaces like polyethylene.

- Composite Pipes: Surface irregularities and varying textures can complicate pipe label application.

Differences in Pipe Sizes: Pipes come in various diameters, from small tubes to large conduits. Labeling these diverse sizes can be challenging, as standard pipe markers may not fit or adhere properly to all pipes.

- Small Pipe Diameter: Limited surface area makes it difficult to place readable pipework labels.

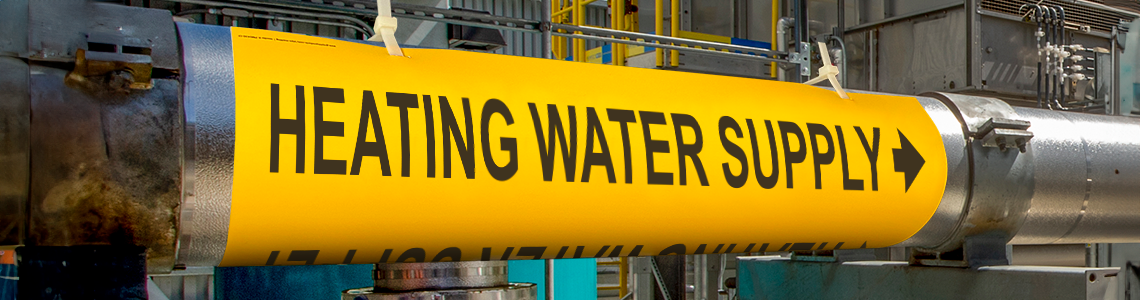

- Large Pipe Diameter: Labels may need to be oversized to be legible from a distance.

Environmental Conditions: Pipes are often exposed to harsh environmental conditions, including extreme temperatures, moisture, chemicals, and UV radiation. Labels must withstand these conditions without fading, peeling, or losing adhesion.

- Extreme Temperatures: Pipe marking labels may fail if not designed to handle the specific temperature range.

- Chemical Exposure: Corrosive substances can degrade labels.

- UV Exposure: Sunlight can cause pipe labels to fade or become brittle over time.

Regulatory Compliance: Ensuring compliance with various industry pipe labeling standards and regulations (such as the Occupational Safety and Health Administration (OSHA), American National Standards Institute (ANSI), and International Organization for Standardization (ISO) is crucial. These pipe labeling standards often specify pipe label size, color coding, and information requirements, adding complexity to the labeling process.

Legibility and Durability: Pipework labels must remain legible over time to provide critical information for safety and maintenance. This includes the text size, contrast, and overall design of the label.

Pipe Labels’ Six Keys to Make Compliance Easy

- Select the Right Pipe Label Material and Adhesive

Choose pipe markers made from materials that match the pipe's surface and environmental conditions. For example, use high-temperature-resistant pipework labels for pipes exposed to extreme heat and chemical-resistant labels for pipes in corrosive environments. Ensure the adhesive is compatible with the pipe material to guarantee strong and lasting adhesion.  Use Flexible and Conformable Pipe Labels

Use Flexible and Conformable Pipe Labels

Flexible labels can conform to curved surfaces, making them ideal for a small pipe diameter. Consider using wrap-around pipework labels or flag-style labels for pipes with limited surface area. For a large pipe diameter, use oversized labels that are easily readable from a distance.- Employ Protective Coatings and Laminates

Protect pipe markers from environmental damage by applying laminates or protective coatings. These additional layers can enhance resistance to UV radiation, chemicals, and abrasions, ensuring the labels remain legible and intact over time. - Implement Clear and Consistent Pipe Labeling Standards

Develop and maintain clear pipe labeling standards within your organization. Use consistent color codes, symbols, and text sizes as per industry regulations. Regularly review and update these standards to stay compliant with the latest requirements. - Regular Maintenance and Inspection

Conduct routine inspections and maintenance to ensure pipe marking labels remain intact and legible. Replace damaged or faded labels promptly to maintain safety and compliance. - Leverage Technology

Utilize advanced printing technologies, such as thermal transfer printing, to produce high-quality and durable pipe labels. Consider using QR codes or RFID tags to provide additional information and enhance traceability.

By adhering to these guidelines, organizations can maintain legible, durable, and compliant pipe labels, enhancing safety and efficiency.

DuraLabel Pipe Labels and Markers Perfect for Your Facility

DuraLabel has become the global leader in workplace labeling and signage by providing visual communication solutions backed by lifetime support and service. Labeling different types and sizes of pipes effectively requires careful consideration of the unique challenges posed by material variations, environmental conditions, and regulatory requirements. We simplify pipe marking with premade pipe labels, valve tags, and other tools to support OSHA requirements, ANSI/ASME A13.1 and International Institute of All-Natural Refrigeration (IIAR) pipe marking guidelines. Duct and pipe marking delivers durable supplies that ensure reliable and long-lasting labels for all your indoor and outdoor pipe marking needs.

Stick, snap, or tie on your facility’s pipes into compliance:

Stick: DuraLabel’s easy-to-apply adhesive pipe markers stick directly onto the pipe. The Adhesive Pipe Marking Labels’ industrial strength adhesive ensures a strong bond on most industrial surfaces. Simply peel and stick it in place.

Snap: The Coiled Pipe Markers quickly attach to pipes via plastic memory. No adhesive or other fasteners are needed. Workers can quickly and securely snap on small to medium-sized pipe marking.

Tie On: These reusable and identifiable pipe markers work on the most dirty, rough, wet, or oily pipes. Utilize Zip Tie-On Pipe Markers for pipe contents including oil and gasoline, steam, acid, or other substances.

DuraLabel Pipe Label Solutions

With countless pipe label and marker options for a variety of pipes, a reliable industrial printer is essential. A DuraLabel industrial sign and label print system—like the DuraLabel Toro Max Industrial Sign and Label Print System—is designed to handle the demands of diverse environments to guarantee that pipe labels remain legible and intact, regardless of the conditions. Whether dealing with extreme temperatures, chemical exposure, or UV radiation, DuraLabel printers produce high-quality labels that adhere well to various pipe materials, including metals, plastics, and composites. The best part is that you can print these pipe marking labels on demand at your worksite instead of waiting for a shipment of pre-printed pipe markers.

Using a DuraLabel printer simplifies compliance with industry pipe labeling standards and regulations such as OSHA, ANSI, and ISO, which often specify label size, color coding, and information requirements. By ensuring your pipe markings are clear, durable, and compliant, you enhance both safety and operational efficiency.

For more detailed guidance on pipe marking, download DuraLabel's free Pipe Marking Instant Action Guide. This comprehensive resource provides valuable insights and practical tips to help you tackle the challenges of pipe labeling effectively. Whether you are labeling small-capacity water lines or large chemical pipes, the guide will help you implement best practices and maintain a safe, compliant work environment.

Read Next:

Facility Safety and Compliance: Utilizing the Right Pipe Markers

Ammonia Refrigeration Safety Fundamentals: Pipe Marking and Beyond

Related Resources

BS 1710 British Standard Pipe Marking

British Standard 1710 (BS 1710) provides a robust framework that fulfills the pipe marking requirements set ...

Read

How Sun Exposure Affects Pipe Labels

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and ...

Read

How to Meet IIAR Standards for Ammonia Pipe Marking

For safe operations and maintenance, its important employees know what's inside the pipes they're working ...

Read.png)