OSHA Construction Site Compliance

OSHA construction compliance is a key element for maintaining a safe jobsite. According to OSHA, nearly 6.5 million people work at over 250,000 construction sites each day. With the inherently hazardous work, it's not surprising that the construction industry has a fatality rate that is higher than the national average among all other industries. To help reduce fatalities OSHA has developed a series of comprehensive standards. These standards are included in 29 CFR 1926, Safety and Health Regulations for Construction.

What Are OSHA Construction Site Requirements?

CFR 1926 includes 27 subparts, covering topics ranging from general safety to crane safety. The subparts are arranged in the following categories:

|

A - General |

O - Motor Vehicles, Mechanized Equipment, and Marine Operations |

|

B - General Interpretations |

P - Excavations |

|

C - General Safety and Health Provisions |

Q - Concrete and Masonry Construction |

|

D - Occupational Health and Environmental Controls |

R - Steel Erection |

|

E - Personal Protective and Life Saving Equipment |

S - Underground Construction, Caissons, Cofferdams, and Compressed Air |

|

F - Fire Protection and Prevention |

T - Demolition |

|

G - Signs, Signal, and Barricades |

U - Blasting and the Use of Explosives |

|

H - Materials Handling, Storage, Use, and Disposal |

V - Power Transmission and Distribution |

|

I - Tools-Hand and Power |

W - Rollover Protective Structures; Overhead Protection |

|

J - Welding and Cutting |

X - Ladders |

|

K - Electrical |

Y - Commercial Diving Operations |

|

L - Scaffolds |

Z - Toxic and Hazardous Substances |

|

M - Fall Protection |

CC - Cranes and Derricks in Construction |

|

N - Helicopters, Hoists, Elevators, and Conveyors |

Looking at the topics covered by CFR 1926, maintaining a safe jobsite seems like an insurmountable task. However, starting with the most frequent construction safety issues will go a long ways toward maintaining a safe jobsite.

Frequent Construction Safety Issues

Part of improving safety includes understanding the most frequent hazards and training employees how to recognize, avoid, and even mitigate those hazards. This is the first line of defense when it comes to your workers' health and safety.

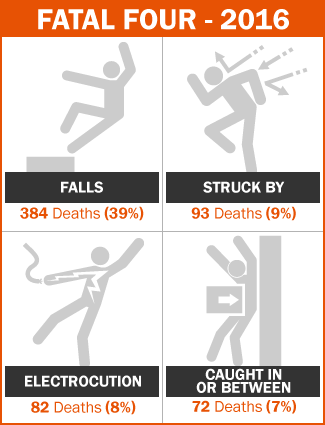

In construction, there are four major hazards that account for most fatalities, according to the Bureau of Labor (BLS). These hazards are commonly referred to as the "Fatal Four" and include falls, electrical hazards, falling objects, and crush hazards. These hazards can be encountered from numerous sources, some of which include:

- Falls - working from ladders, scaffolding, lifts, and roofs.

- Electrical hazards - overhead power lines, conduits, underground power lines, and equipment that has not been properly de-energized using Lockout/Tagout (LO/TO) procedures.

- Falling objects - tools and equipment left on roofs, equipment, ladders, lifts, and more.

- Crush hazards - swing zones of heavy equipment (excavators, drilling equipment, etc.), crush zones under lifts, between equipment and fixed objects, and much more.

Of these hazards, falls alone account for nearly 39% of construction fatalities. To improve construction safety and reduce falls, Duralabel' created an OSHA Fall Protection Guidelines and Standards Infographic to help educate workers about about fall hazards as well as the safety devices that can help you mitigate those hazards.

Steps for Maintaining a Safe Jobsite

While understanding the most common safety issues you may face in construction is important, there are some additional steps that must be taken to maintain a safe jobsite, such as:

- Training all employees about the hazards they may face, paying special attention to the Fatal Four.

- Conducting a complete walkthrough of the site to identify hazards before breaking ground. Make note of these, so you can mitigate them using engineer controls, safe work practices, PPE, or regular maintenance.

- Creating a site safety plan that accounts for all potential hazards as well as provides a means to respond to any accident.

- Identifying all hazardous materials and labeling them according to HazCom 2012.

- Inspecting the worksite on a daily basis to identify new hazards and malfunctioning equipment. Immediately report and fix any issues found.

- Ensuring employees have the necessary PPE to perform work safely. This includes hard hats, eye protection, gloves, work boots, hearing protection, respiratory protection, fall protection, and more.

- Creating an injury and illness prevention program. Programs should include first aid training, supplies needed to treat common workplace injuries, and a means to contact local emergency services.

- Identifying hazards and communicate safe work practices using vivid labels and signs.

Learn how to create safety signs that meet OSHA requirements with Duralabel' Best Practice Guide to OSHA Safety Signs. This helpful guide breaks down all the requirements, from text size, to color and graphics-ensuring your safety signs are seen and compliant.

As a final note, make sure your construction site complies with all OSHA standards. To ensure you are meeting OSHA standards, it's important to understand the requirements in 1926, as well as other standards. For example, there may be cases where you encounter a hazard that is not covered by 1926. In these cases, the hazard may fall under the General Industry Standard (29 CFR 1910) or Section 5 of the Occupational Safety and Health Act, known as the General Duty Clause. The General Duty Clause provides an all-inclusive safety requirement that requires employers to mitigate or remove recognized hazards that have caused or may cause injury or death. While this is a lot to keep track of, once you are familiar with OSHA standards, you will be able to quickly identify most hazards by performing daily walk-around inspections of your site.

Related Resources

The Benefits of OSHA Requirements and Compliance

The Occupational Safety & Health Administration (OSHA) is dedicated to ensuring the safety and well-being ...

Read

OSHA 1926 Requirements

What are OSHA 1926 requirements? The Occupational Safety and Health Administration’s (OSHA) 29 CFR 1926 ...

Read

From Flash to Ash: Understanding Arc Flash Hazards and Prevention

What is Arc Flash? When it comes to electrical safety, arc flash is one of the most dangerous—and most ...

Read.png)