Wearable Safety Technology Takes Safety From Reactive to Real Time

How Does Wearable Technology Improve Workplace Safety?

Wearable technology improves workplace safety by giving workers and supervisors real-time monitoring, fast communication, and immediate alerts when conditions turn risky. These tools help prevent incidents, speed up response times, and reinforce safe behavior on the job. As a result, wearables are becoming a practical safety upgrade across high-risk industries.

The sections below break down how wearables work, where they add the most value, and what to consider before rolling them out.

-

What workplace hazards wearables can detect early

-

How real-time alerts reduce injuries and downtime

-

Common wearable safety tools used across industries

-

Where wearables support OSHA and ANSI expectations

-

Best practices for implementing wearable safety programs

Wearable technology is a transformative solution, offering real-time monitoring, communication, and support that redefine workplace safety standards. The sections ahead look at the impact of wearables on enhancing worker safety and their diverse applications across industries

Solving Workplace Challenges with Wearable Safety Technology

Wearable technology is proving instrumental in addressing diverse challenges within industrial workplaces, particularly in enhancing safety protocols and operational efficiency. For instance, wearables provide:

- Real-time data to workers about potential hazards and safety violations

- Aiding in injury prevention

- Reducing lost work time

- Mitigating workers' compensation claims

Biometric monitors integrated into wearables can track vital signs like heart rate variability, breathing volume, and even detect sleepiness using smart glasses. Companies can monitor the precise location of workers and equipment on a worksite, allowing for proactive safety measures by leveraging GPS and Bluetooth technologies.

In the construction and manufacturing industries, where workplace hazards are common, wearable technology plays an important role in worker safety. In the construction sector, smart helmets equipped with vibration sensors alert employees to potentially dangerous environmental changes. Similarly, high-tech vests with sensors can notify construction workers when they enter hazardous areas, further enhancing on-site safety. In manufacturing, wearables are deployed to detect worker proximity to heavy machinery, alerting equipment operators and potentially preventing accidents. Proximity sensors integrated into wearables have the potential to significantly reduce fatalities caused by forklift collisions, potentially saving lives.

Beyond safety improvements, wearables contribute to operational efficiency by granting workers instant access to critical information, automating tasks, and optimizing processes. This data-driven approach allows companies to:

- Monitor employee performance

- Track equipment status and location

- Improve worker training and development initiatives.

Notably, companies like UPS and FedEx leverage handheld scanners and monitors to track all packages entering and exiting trucks, empowering operation supervisors to measure individual performance in real-time and allocate resources effectively to maintain productivity levels.

Wearable Technology Tools That Protect Workers

Wearable technology can improve worker productivity, efficiency, and compliance by providing data collection, analysis, and feedback. Today’s wearable safety technology includes tools for hazard detection, health monitoring, and hands-free communication, such as:

- Augmented reality glasses provide workers with real-time information, guidance, and alerts about their tasks and environment.

- Environmental monitoring devices measure and warn workers about hazardous substances, such as gases, VOCs, heat, cold, noise, or radiation.

- Proximity warning systems detect and prevent collisions between workers and vehicles or machinery.

- Worker vital sign monitoring devices tracks and alert workers and supervisors about health issues, such as heart rate, blood pressure, fatigue, stress, or dehydration.

- Lone worker monitoring devices enable workers to communicate with emergency services or colleagues in case of an accident or injury.

- Worker ergonomics devices measure and improve workers' posture, movement, and lifting techniques to prevent musculoskeletal disorders.

- Smart hard hats protect workers from head injuries and provide them with features such as cameras, sensors, GPS, or speakers.

- Wearable cameras and communication devices capture video footage for incident analysis and documentation and facilitate seamless communication among workers and teams, improving coordination during tasks.

- Exoskeletons provide physical support during heavy lifting or repetitive tasks, reducing strain on muscles and joints.

Benefits of Wearable Technology in Enhancing Safety

Deploying wearable technologies offers a myriad of advantages across various workplace settings, spanning from the job site to the boardroom. Three benefits show up most consistently when companies adopt wearable safety technology.

- Real-Time Health Monitoring: Wearable technology plays a crucial role in enhancing worker safety by providing real-time data and insights that help prevent accidents and injuries. For instance, in a Fujitsu factory, smart wristwear can issue alerts at signs of heat stress, while in mining companies, smart helmets are utilized to detect driver fatigue, thereby mitigating potential safety risks.

- Enhanced Productivity: Wearables contribute to increased productivity by automating tasks, streamlining processes, and granting workers immediate access to critical information. At Cincinnati/Northern Kentucky International Airport, smart watches notify cleaning crews promptly when and where their services are required. This dynamic task scheduling optimizes facility cleanliness, ultimately enhancing the traveler experience.

- Communication and Coordination: Wearables enable companies to monitor employee performance, track equipment status and location, and identify opportunities for process optimization. For instance, Lufthansa has embraced voice-based headphones to empower technicians to accomplish maintenance tasks more efficiently. By converting maintenance checklists into voice commands relayed through headphones, technicians can execute tasks seamlessly while recording real-time data automatically.

Moreover, the adoption of wearables contributes to cost reduction associated with accidents, downtime, and lost productivity. By improving profitability and facilitating the collection of real-time data, wearable technology enables organizations to identify growth opportunities and drive innovation effectively.

Challenges and Considerations

Addressing challenges to the successful deployment of wearable technology is essential for maximizing its effectiveness in the workplace. The success of wearable technology hinges on comprehensive deployment plans, adequate training for users, and employee acceptance. Some individuals may resist using wearables if they perceive them as intrusive surveillance tools. However, incorporating features like built-in man-down alarms, such as those found in air packs for firefighters, gas monitors, bio harnesses, and communication devices, can enhance user comfort and reduce concerns about privacy.

Several challenges accompany the adoption of wearables in the workplace, along with strategies to mitigate them.

Data Privacy: Concerns may arise due to the collection of extensive employee data, including biometrics and location information. Transparent communication with employees about data collection, usage, and protection is crucial to address these concerns effectively.

Employee Acceptance: Engagement and adoption are critical for the successful implementation of wearables. Some workers may be hesitant, fearing privacy violations or performance monitoring. Educating employees about the benefits of wearables can foster acceptance and ensure a positive experience with this technology. Notably, younger employees are often more receptive to innovative technologies and can serve as early adopters and advocates for new gear.

Cost: Financial considerations may impede widespread wearable deployment. However, advancements in technology have driven down prices of devices like smartwatches, Fitbit, hand scanners, and proximity sensors by as much as 18% annually. Despite initial investment challenges, the potential savings from reduced injury-related costs and enhanced productivity outweigh these upfront expenses. By addressing these challenges effectively, organizations can leverage wearable technology to enhance safety, efficiency, and employee well-being in the workplace.

Today’s Wearable Technology Leaders

Here are three examples of leading companies leveraging wearable technology to drive significant improvements in their operations:

Boeing

Boeing, a global leader in aerospace, has integrated wearable technology into their manufacturing processes to enhance worker safety and productivity. They introduced "Boeing VisionAR" and "Boeing Torque-Ready" smart glasses, which guide workers during electrical assembly and harness routing, reducing documentation time by 25 percent. These wearables also facilitate inventory monitoring across the factory floor, ensuring optimal part placement and significantly reducing human error while improving overall manufacturing efficiency.

General Electric

General Electric (GE) employs wearable technology to track worker movements, monitor energy consumption, and optimize workflow. Their "Smart Helmet" features cameras, sensors, and voice recognition systems, providing real-time data streams to workers. In GE's aviation unit, the Smart Helmet offers visual guidance and progress tracking, ensuring worker efficiency and maintaining consistent quality. This innovative use of wearables at GE has yielded valuable insights, enhancing productivity on the factory floor.

PepsiCo

PepsiCo embraces wearable technology to enhance worker safety by equipping employees with advanced vests designed for ergonomic monitoring. These vests are equipped with sensors that collect data on posture, lifting techniques, and movements. PepsiCo leverages this data to foster collaboration between workers and ergonomics experts, identifying and mitigating potential injury risks through targeted training initiatives. PepsiCo's innovative approach to workplace safety using wearables has garnered recognition for its effectiveness in addressing safety concerns.

The Next Steps in Wearable Technology

Wearable technology is poised to revolutionize safety measures through predictive analytics and artificial intelligence (AI). Wearables powered by AI can utilize predictive analytics to anticipate safety risks and recommend personalized safety measures, enabling proactive accident prevention strategies based on data patterns. Additionally, the integration of wearables into Internet of Things (IoT) and connected worker platforms will enhance workplace safety by facilitating real-time monitoring of multiple parameters and seamless integration with existing safety systems. This interconnected approach ensures efficient responses to safety incidents and enables data-driven decision-making for optimal safety protocols. Looking ahead, wearable technology is set to offer even more customized solutions, including biometric authentication and adaptive features tailored to individual worker needs. Collaborative research and development efforts will drive these innovations, shaping the next generation of workplace safety solutions that prioritize employee well-being and accident prevention.

Conclusion

Wearable technology represents a pivotal shift in workplace safety, providing real-time insights, enhancing communication, and preventing accidents. As organizations embrace these innovations, the future promises safer, more efficient workplaces where worker well-being is prioritized. Let us champion the potential of wearables and cultivate a safety culture that starts with leveraging the right tools and technology to protect our most valuable asset—our workforce. Safety isn't just a policy—it's a commitment to empowering workers with the tools they need to thrive in modern work environments.

DuraLabel’s free OSHA Signage Instant Action Guide can help create OSHA/ANSI-compliant safety signs and custom labels with ease. Need help assessing your facility? This guide also includes a site inspection checklist.

Read Next:

Related Resources

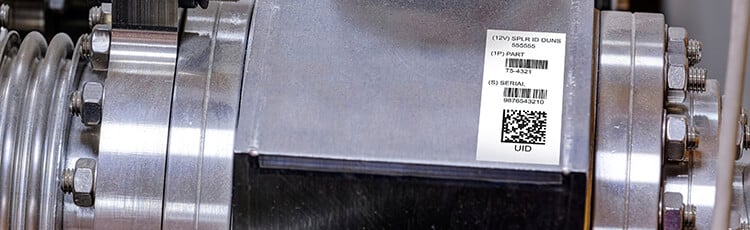

Achieve IUID Compliance with Thermal Transfer Printing

What is the Goal of the IUID System? The Item Unique Identification (IUID) or MIL-STD-130 standard was ...

Read

Why Upgrade to the DuraLabel Toro Max Industrial Sign and Label System

What are the Key Benefits of Upgrading to the DuraLabel Toro Max Industrial Label Printer? In demanding ...

Read

Why Upgrade to the DuraLabel Bronco Max Industrial Sign & Label System

What Makes the Bronco Max a Smart Industrial Labeling Upgrade? Facilities that start with office-grade ...

Read.png)