The Case for Custom Workplace Signs in Complex Environments

Why Do Custom Industrial Labels Outperform Standard Signs in Facility Environments?

Custom workplace signs outperform standard signs because they reflect real, site-specific hazards instead of generic assumptions. In fast-moving facilities with multilingual teams, shifting layouts, and overlapping risks, tailored signs give clearer direction, reduce confusion, and hold up in harsh conditions. That makes them more effective for both safety and compliance.

The table below compares standard signs and custom industrial labels.

| Feature | Custom Industrial Labels | Standard Signs |

|---|---|---|

| Hazard specificity | Site-specific hazards | Generic warnings |

| Workforce fit | Multilingual & role-based | One-size-fits-all |

| Durability | Industrial-rated materials | Office-grade materials |

| Compliance longevity | Built to maintain compliance | Often degrades |

| Adaptability | Updatable, QR-enabled | Static |

Five factors explain why standard signage falls short in industrial settings and how custom workplace signs close those gaps:

-

Why hazard communication signage still fails in real facilities

-

Where generic signs miss site-specific risks

-

How custom signs improve clarity for diverse teams

-

Why durability matters in harsh environments

-

What modern custom workplace signs can include

Hazard communication consistently ranks among OSHA’s most-cited violations, even when facilities have signage posted. According to the Occupational Safety and Health Administration (OSHA), hazard communication remains one of the most frequently cited workplace violations. In 2023, it ranked third among all citations, with more than 3,200 violations nationwide. In many cases, signage either failed to reflect actual hazards or was not understood by the intended audience.

In fast-moving industrial environments, that disconnect matters. Generic signs may satisfy minimum regulatory requirements, but they often fail to reflect the real risks workers face on the ground. As operations grow more dynamic with multilingual teams, mobile machinery, and overlapping hazard zones, standard signage frequently falls short of providing the clarity workers need.

Custom workplace signs solve that problem by delivering targeted communication. They identify specific hazards, support multilingual instruction, and can include tools like QR codes for quick access to updated procedures. They are also built for industrial conditions, so they stay readable where standard materials fade, peel, or fail. In facilities where safety depends on context, custom signs are not a nice-to-have upgrade. They are the difference between a warning that gets noticed and one that gets ignored.

Design tools also play a role in whether custom signage is implemented consistently. Software such as LabelForge® PRO Design Software allows safety and operations teams to create, update, and standardize industrial labels on demand, without relying on external design resources. By supporting ANSI formatting, variable data fields, and quick revisions, labeling software help ensure signage stays aligned with changing hazards, procedures, and compliance requirements.

The Role of an ANSI-Compliant Signage Provider in Regulatory Compliance

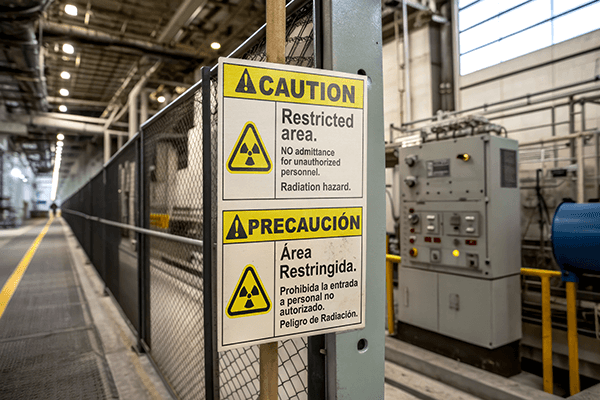

OSHA requires workplace signage to reflect actual hazards under 29 CFR 1910.145. The American National Standards Institute (ANSI) provides detailed formatting guidance in the ANSI Z535 series, which is widely recognized as the industry benchmark.

A trusted ANSI-compliant signage provider helps ensure every sign:

- Follows ANSI Z535 formatting and OSHA 1910.145 placement requirements

- Uses signal words and pictograms correctly based on hazard severity

- Meets durability requirements for the environment where it’s placed

- Aligns with internal protocols and evolving safety plans

Common signage mistakes include misusing signal words, applying incorrect label formatting, or choosing materials that quickly degrade under site-specific conditions. For example, using “Caution” instead of “Danger” for a high-voltage panel can downplay risk, while a standard adhesive label placed in a damp environment may peel or fade within weeks. These oversights are often unintentional, but they can lead to compliance failures and serious safety consequences. A knowledgeable signage provider helps prevent these pitfalls before they become violations.

Signage compliance is not just about what gets printed. It’s about how that sign performs in the environment where it’s placed. Materials must withstand abrasion, moisture, temperature shifts, and chemical exposure. Even small lapses in durability or clarity can lead to safety breakdowns over time.

That’s why many facilities rely on providers with proven experience in demanding environments. DuraLabel®, for example, has supported industrial safety programs for more than 50 years and is known for its tough-tested labeling systems. That kind of field-tested reliability matters when signage must do more than meet formatting rules. It must endure, inform, and protect.

How Visual Manage Signage Improves Communication and Safety in Complex Layouts

In environments with layered operations, multiple teams, or continuous movement, verbal instructions alone are rarely sufficient. Visual management signage provides immediate, at-a-glance information that helps standardize workflows and reinforce safe behavior.

Effective visual systems often include:

- Work zone indicators to designate tasks or restricted access

- Path markings to separate pedestrian and equipment traffic

- Tool outlines and labels for lean inventory practices

- Color coding for maintenance, inspections, or hazard states

These visual tools support lean and Six Sigma programs, but their value goes beyond methodology. They help people navigate dynamic spaces safely, especially in facilities with changing conditions and high turnover.

Custom signage reinforces these systems by closing communication gaps that arise in fast-changing conditions. For example:

- Chemical processing plants may require PPE signage that changes daily based on the materials in use. Custom signs with QR codes or interchangeable fields help ensure the right protocols are followed.

- Construction sites shift layouts frequently. Multilingual hazard notices and temporary access signs reduce confusion among contractors from multiple firms.

- Food and beverage facilities rely on clear hygiene boundaries. Color-coded signs and custom labels help prevent cross-contamination by guiding clean and dirty workflows.

- Warehouses and distribution centers adjust signage to account for seasonal hazards, traffic changes, or maintenance zones. Custom labels provide the flexibility to update these markers in real time.

In each case, the signage must do more than inform. It must respond to conditions on the ground. That’s where custom visual communication makes the difference.

When Hazard Communication Signage Makes the Difference

Hazard communication signage must comply with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), as adopted by OSHA under the Hazard Communication Standard (29 CFR 1910.1200). Effective signage should:

- Use GHS-compliant pictograms, signal words, and hazard statements

- Identify specific substances, not just general hazard classes

- Remain visible despite exposure to chemicals, abrasion, or UV

- Indicate PPE requirements and outline emergency response steps

GHS-aligned labels also support safety training by reinforcing information covered during onboarding and safety briefings. When signage mirrors what workers have learned, it builds consistency and reduces hesitation in emergencies.

Clear HazCom labeling also supports audits, inspections, and cross-departmental communication, particularly in facilities where teams may not regularly handle the same materials.

This is especially relevant for operations governed by the National Fire Protection Association (NFPA), which recommends distinct visual identifiers for chemical storage and emergency response planning.

In facilities managing flammable, toxic, or reactive substances, there is no room for ambiguity. Customized HazCom signage ensures that the right information is presented clearly, consistently, and at a critical moment.

DuraLabel Recommended Product for Complex Environments

Standard signage is rarely sufficient in today’s industrial environments. Complex layouts, multilingual teams, and variable hazards require clarity that only custom workplace signs can deliver. From regulatory compliance to day-to-day communication, customized signage helps facilities meet modern safety standards without compromise.

DuraLabel offers a comprehensive suite of visual communication solutions designed for dynamic facility needs. For operations managing mobile equipment, chemical hazards, and shifting layouts, the DuraLabel Kodiak® Max Industrial Sign and Label System delivers durable, facility-ready signs and labels on demand. Paired with LabelForge PRO Design Software, teams can build consistent ANSI-style layouts, apply standardized templates, and update messaging quickly as hazards, processes, or floor plans change.

To support your team’s safety goals, DuraLabel’s free OSHA Signage Quick Start Guide provides practical steps for assessing facility signage needs and implementing compliant visual communication strategies. It includes guidance on selecting proper sign headers, understanding ANSI formatting requirements, aligning with GHS label standards, and choosing durable materials for challenging industrial conditions.

Need expert support? Call 1-888-789-7964 to speak with a DuraLabel signage specialist and get started on a safer, more customized workplace.

Read Next:

Mission-Ready Fire Safety Starts with the Right Exit Signs

5S Examples in Action: The Good, The Bad, and The Successful

Related Resources

5 Ways to Make Workplace Safety Signs Stand Out

How Safety Signage Improves Hazard Communication and Employee Awareness Workplace safety signs play a key ...

Read

How OSHA 1910.145 Defines Workplace Safety Signs and Tags

What Does OSHA 29 CFR 1910.145 Require for Safety Signs and Tags? OSHA 29 CFR 1910.145 establishes the ...

Read

Everything You Need to Know To Be OSHA Signs and Labels Compliant

How Does OSHA Signage Compliance Support Workplace Safety? Occupational Health and Safety Administration ...

Read.png)