Pipe Marking & Pipe Corrosion Control

The Silver Eagle Refinery explosion released a tidal wave of broken glass.

Homes were pushed off their foundations and countless workers were burned in the Utah-based petroleum refinery when a 10-inch pipe ruptured at the bottom of a reactor. The result was a hydrogen explosion and fire that would shake the sleepy city of Woods Cross.

The accident was caused by a rupture in a pipe that had become dangerously thin from corrosion, according to a 2014 report from the U.S. Chemical Safety Board. The accident could have been prevented were proper inspection strategies put in place along with reliable pipe marking that is compliant with the Occupational Safety and Health Administration (OSHA).

Annual pipe inspections are integral to providing a safe workplace environment. While potentially expensive and time-consuming—especially in large facilities—a comprehensive plan and routine maintenance schedule should be established. When examining pipes, safety professionals should examine not only the structure quality of the pipe, but its pipe marking labels as well.

The Role of Pipe Marking in Preventing Corrosion

Corrosion poses a significant threat to pipelines across various industries, including nuclear and fossil power plants, petrochemical facilities, and oil refineries. This natural process can lead to billions of dollars in damage annually by gradually destroying metals through chemical reactions.

Rusting, the most common form of corrosion, transforms metal pipes into iron oxides or salts when exposed to oxygen and moisture. This deterioration undermines the structural integrity of pipes, which is critical for maintaining safety and efficiency.

Effective pipe marking is essential in mitigating the risks associated with corrosion. Proper pipe markers and pipe labels can help in identifying the type of pipe and its contents, such as using gas pipe labels to denote gas lines. OSHA pipe labeling standards ensure that pipes are correctly marked to meet safety regulations, reducing the likelihood of accidents and facilitating maintenance.

Corrosion can be caused by:

- Salts and osmosis

- Water permeability

- Adhesion problems

- Surface preparation

- High-temperature deterioration

- Crevice corrosion in confined spaces

- Microbiologically-influenced corrosion

Corroded material is chemically removed with substances like phosphoric acid, but preventative measures—including surface treatments and applied coatings—are more commonly used. Enamel applications, painting, plating, and galvanizing are the most common anti-corrosion treatments, which provide a barrier of corrosion-resistant material between the damaging environment and the pipe. Additionally, the use of gas line pipe tape can provide extra protection and help maintain the effectiveness of the pipe markers and pipe labels.

By integrating pipe marking solutions with corrosion prevention strategies, facilities can better safeguard their pipelines and extend their operational lifespan.

What is Pipe Marking?

Pipe markers ensure workers are not only aware of pipe contents, but potential hazards, and the direction of flow associated with the materials inside the pipe. Bold, simple, and consistent OSHA pipe labeling methods convey this information to reduce hazards and ensure OSHA and American National Standards Institute (ANSI) pipe marking standards are met.

Pipe markers ensure workers are not only aware of pipe contents, but potential hazards, and the direction of flow associated with the materials inside the pipe. Bold, simple, and consistent OSHA pipe labeling methods convey this information to reduce hazards and ensure OSHA and American National Standards Institute (ANSI) pipe marking standards are met.

Industrial pipe marking standards exist and requirements vary between local authorities. The most common standard, ANSI/ASME A13.1, provides a frame of reference for most pipe marking projects.

Effective pipe marking programs and pipe marking best practices help improve facility efficiency and increase safety through visual communication. Effective programs combine ANSI pipe marking color codes, label sizes, printed text and arrows, and marker positioning to create clear consistent messages for compliance and safety.

Inspecting Your Facility's Pipe Marking

Combine resources and time by creating an integrated pipe marking and corrosion walk through in your facility to ensure your pipe labels are complete and your pipes are in a safe condition.

Pipe check data acquisition and analysis software uses 3D scanning technology to address pipe corrosion, depth, and mechanical damages. Piping and Instrumentation Diagrams (P&IDs)—or the document of record—are also used to ensure successful repairs and pipe maintenance is performed.

Labeling assistant applications aid with OSHA pipe labeling, allowing users to take photos, add notes, and reference exact pipe label locations with automatic geo-tagging. When examining pipe markers and labels look for:

Existing Markers

- Check for damage, fading, discoloration, and readability.

- Are the pipe labels accurate?

- Do they comply with your current marking color scheme?

Pipes Without Markers

- Look out for new equipment, or old equipment, that has recently been altered.

- Have pipe markers been removed or lost? What caused that removal?

- If a pipe or fitting has no identification, why not? The answers may lead you to a better understanding of your facility's unique needs.

Pipe Markers That Can't Be Clearly Seen

- Are existing pipe labels sized appropriately and visible from an ordinary viewing position?

- Would a different viewing position make it difficult to see the pipe marking?

- Would hanging valve tags or signs be a more effective way to mark a given pipe or fitting?

As you conduct your facility inspection, refer to a piping schematic or facility plan. Make sure that all the pipes that appear in the plan are actually present in your facility, and vice versa. A pipe system must include all sources, distribution, mixing, and discharge pipes, as well as all of the fittings, valves, and tanks that they connect, and ensure to include locations of shut-off valves.

Each item should be accurately recorded on your schematic. As the project continues, you can use the schematic to create a list of any new pipe markers that need to be created, and old ones that need to be updated.

DuraLabel Pipe Marking Solutions

Pipe marking is crucial for identifying the contents and direction of flow within industrial pipelines. The OSHA pipe labeling helps workers navigate complex pipe systems safely and efficiently while detailing what each pipe carries. Understanding how to make and use pipe labels properly boosts safety and compliance with regulations in the workplace.

Having the right tools can make a big difference when creating reliable pipe labels. It's important to find a high-quality printer that simplifies the creation of these labels. Whether you need safety signs, pipe markers, or equipment labels, the DuraLabel Kodiak Max Industrial Sign and Label Print System is ready to meet your needs with its easy-loading ribbons and 9" full-color touchscreen.

With ongoing education and training, workers can ensure the pipe marking effectively communicates important information, protecting both people and the environment.

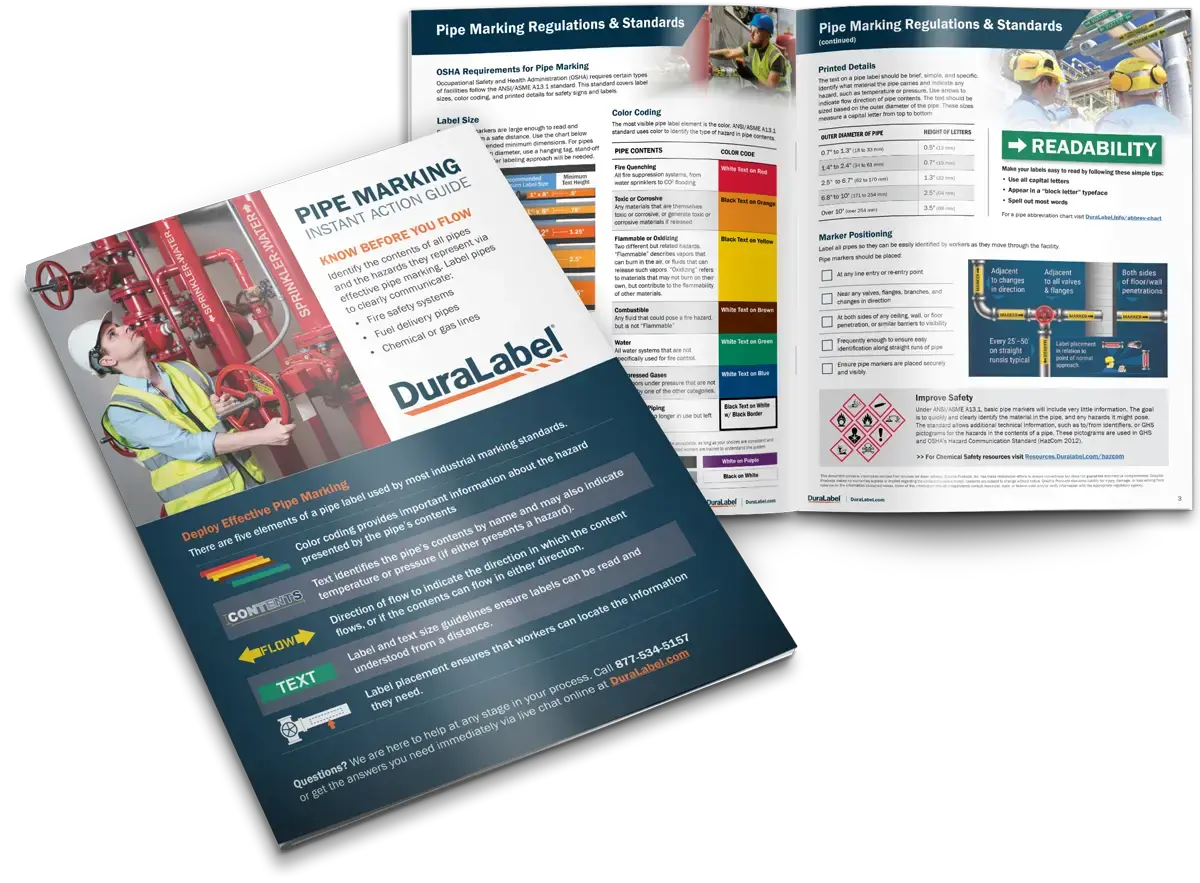

A great way to learn more about pipe marking is with DuraLabel’s free Pipe Marking Instant Action Guide. This guide helps you stay compliant with OSHA and ANSI standards, understand the hazards that might be in the pipes, and keep up with industry-specific rules. For further pipe marking assistance, including a complimentary webinar, visit DuraLabel.com or call 1.888.973.2045 to speak with a customer service representative.

Read Next:

Navigating Pipeline Pathways with Directional Pipe Markers

Related Resources

.png)

Navigating Pipeline Pathways with Directional Pipe Markers

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These ...

Read

The Benefits of Pipe Marking

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe ...

Read

Winery Safety: Common Violations and How to Stay Safe

Many of us romanticize the image of a wine maker caring for the vines, tending the fresh earth, hosting ...

Read.png)