The Benefits of Pipe Marking

Pipe Marking Benefits

Industrial pipe marking is an economical solution to any facility's complex pipe infrastructure. Properly marked pipes provide essential information where it is needed most, improving safety and increasing efficiency.

Pipe marking is critical for worker safety, because insufficient system knowledge can lead to injury and death.

-

On Feb. 29, 2012, four people were using a cutting torch to demolish an out-of-service petroleum pipe. The pipe had not been purged in over a year. It contained vapors that resulted in an explosion and flash fire. All four workers were scalded, burned, and taken to the hospital. Two were released after 24 hours; the other two remained hospitalized for an extended period of time.

-

An accident occurred when a worker was changing an O-ring in a line heater. He had closed the valve upstream of the heater but, contrary to the required procedure, had not closed the downstream valve. As he was loosening it, the end blew off the pipe, which struck and killed the worker. The average pressure in this system at the time was 8,500 psi.

-

On Sept. 27, 2010, a worker was returning an eight-inch steam header back into service after planned maintenance. The worker, along with three coworkers, was walking along the steam header catwalk checking the valve positions. A two-inch, 90 degree elbow suddenly failed resulting in 1,000 psi, 500 to 650 degree Fahrenheit steam discharging onto the first worker. He was hospitalized for second and third-degree burns over 80 percent of his body.

These kinds of incidents can be prevented through effective and detailed pipe markers.

Elements of Effective Pipe Marking

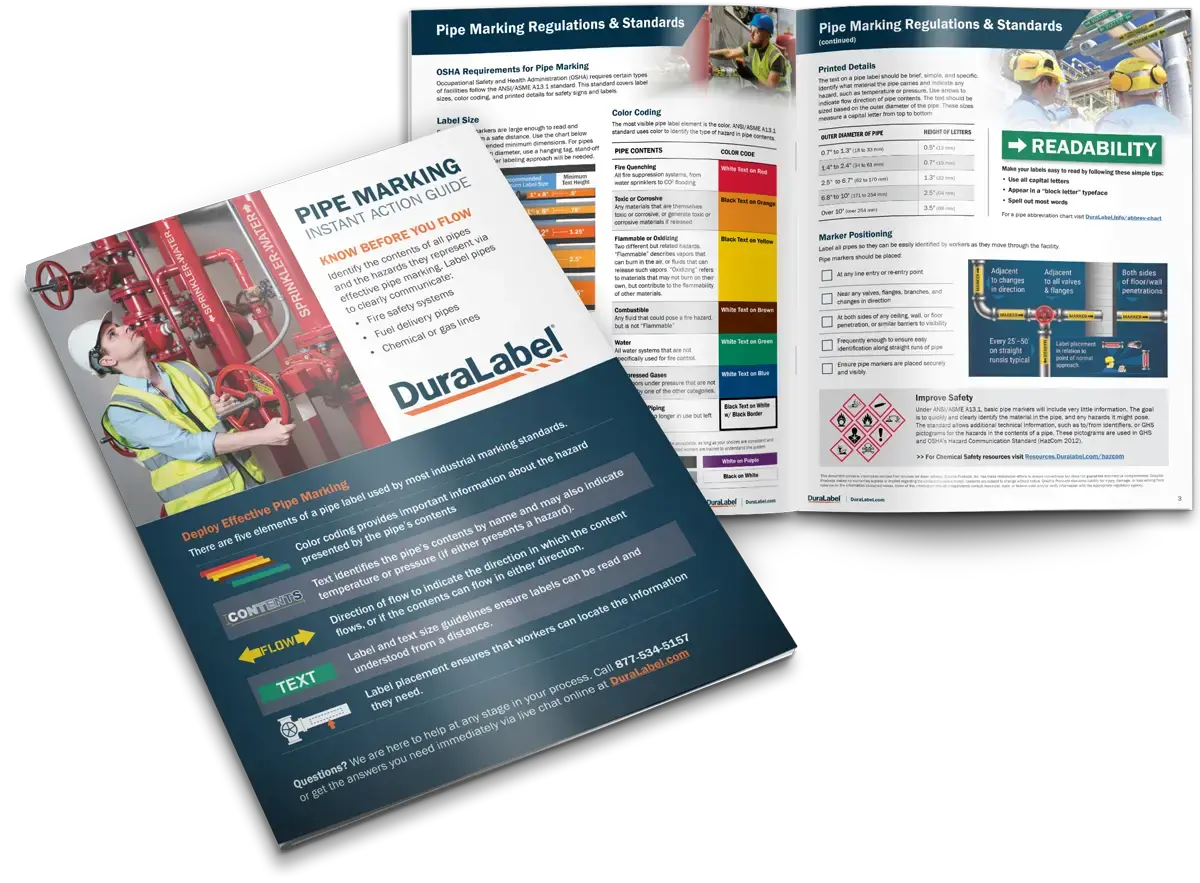

In general, there are five elements that make an effective pipe label. These elements are used by most pipe labeling standards:

-

Color coding provides important information about the hazard presented by the pipe's contents.

-

Text identifies the pipe's contents by name and may also indicate temperature or pressure (if either presents a hazard).

-

Direction of flow to indicate the direction in which the content flows, or if the contents can flow in either direction.

-

Label and text size guidelines ensure labels can be read and understood from a distance.

-

Label placement ensures that workers can locate the information they need.

Each of these elements work together to form a pipe marking system that provides the information workers need most.

Which Pipe Marking Standard Should You Use?

When pursuing the five elements, adhere to industry-wide standards for instant recognition and safety. The standard used will depend on your facility's type and location. There are many pipe labeling standards that may apply in different situations. Some common pipe labeling standards used in the U.S. include:

- ANSI/ASME A13.1 for general pipe marking

- IIAR Bulletin No. 114 for ammonia refrigeration

- NFPA 99 and CGA C-9 for healthcare facilities

- Ten States Standards for water and wastewater treatment facilities

If your facility is in the United Kingdom or Europe, you will need to follow relevant standards, which may include:

- BS 1710-2014 for marking pipes in general facilities, for refrigeration, for water treatment, and more

- The Health and Safety (Safety Signs and Signals) 1996 for general facility pipe marking

No matter where in the world you are located, check with your local authorities to ensure that you are fully complying with the law. Learn more about the elements of pipe markers with the Pipe Marking Best Practice Guide by DuraLabel. The guide covers several pipe labeling standards in great detail, detailing when and how they should be used.

Benefit: Pipe Marking Increases Hazard Awareness

When it comes to pipe markers, workers need a way to accurately and consistently identify the hazards they may face. A pipe label meets this challenge by:

- Presenting information in an easy-to-understand and consistent format

- Enabling workers to identify hazards with a quick glance

- Supporting your facility's overall hazard communication program

A proper pipe label system is well supported by a simple, yet effective pipe marker color code system. ANSI/ASME A13.1 uses six predefined colors and four user-defined colors to identify hazards which is used as the pipe marker color code standard by many organizations, and is referenced by OSHA as the color marking system of choice.

Under the ANSI/ASME A13.1 color standard, workers know immediately that a yellow label means they need to take extra safety precautions for fire hazards. They have an increased safety awareness when and where it matters most.

Pipe markers can also improve safety by supporting your hazard communication program. OSHA requires employers to create an in-depth hazard communication program as part of HazCom 2012. Instead of creating your own customized plan for communicating hazards related to your facility's pipes, take advantage of a relevant pre-existing standard, like ANSI/ASME A13.1. Make it an essential part of your hazard communication and training program.

Benefit: Pipe Marking Increases Worker Efficiency

A pipe label has the added benefit of increasing efficiency and reducing costs. Properly labeled pipes help workers perform daily tasks and maintenance more quickly and with fewer errors. They are more confident about their work environment and can:

- Quickly move from one task to the next, filling beakers and other containers without having to reference charts or binders.

- Spend less time referencing schematics and technical specs. Instead, workers track issues intuitively because much of the needed information is on the pipes.

With a comprehensive marking system, the information is at the point-of-use, reducing errors and mistakes. Workers know the exact contents of a pipe, every time.

DuraLabel Solutions to Get Started with Pipe Marking

When dealing with potential safety issues, a piece of duct tape and a permanent marker are not sufficient marking supplies. Use durable industry-specific premade pipe labels or invest in your own industrial label printer for on-demand pipe marking.

Designing and implementing your own unique pipe marking system, aligned with one of the pipe labeling standards, is easy with DuraLabel's line of DuraLabel printers, supplies, and kits. For facilities where mobility and flexibility would be an asset, choose the DuraLabel Toro Max Industrial Label Printer.

No matter which DuraLabel printer you choose, you can:

- Design pipe markers with just a few clicks using the built-in labeling software

- Create durable labels that will last for many years

- Add hazard pictograms, arrows, and other graphics to meet your facility's unique needs

At the end of the day, what's important is that you invest in a pipe marking solution that helps keep your employees safe and well-informed. To help you get started, we are offering you a free Pipe Marking Quick Start Guide, which will provide you the guidance needed to create more effective pipe markers.

Read Next:

Related Resources

Pipe Marking & Pipe Corrosion Control

The Silver Eagle Refinery explosion released a tidal wave of broken glass. Homes were pushed off their ...

Read.png)

Navigating Pipeline Pathways with Directional Pipe Markers

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These ...

Read

Understanding the ASME A13.1 Standard for Enhanced Pipe Labeling

What is the ASME A13.1 Standard for Pipe Labeling? The American National Standards Institute (ANSI) A13.1 ...

Read.png)