Industry

Manufacturing

Challenge

IPG Photonics needed labels that could withstand tough manufacturing conditions—without peeling, fading, or failing when exposed to oils and frequent handling.

Results

With DuraLabel, the team achieved durable, professional labeling that stays in place and performs reliably across departments and applications.

Key Production

“We had more reliability in the [labels] adhering to the products.”

Michael Hoffman

The Challenge

For IPG Photonics, product labeling is a necessary step in tracking, organizing, and presenting sophisticated laser systems. However, their previous labeling method created reliability issues. Labels often peeled or lost adhesion after exposure to oils or routine handling—causing delays, reprints, and inconsistencies. The team tested alternative solutions but found the results underwhelming. They needed a label that would apply cleanly the first time, stay in place, and maintain a professional appearance in demanding manufacturing conditions.

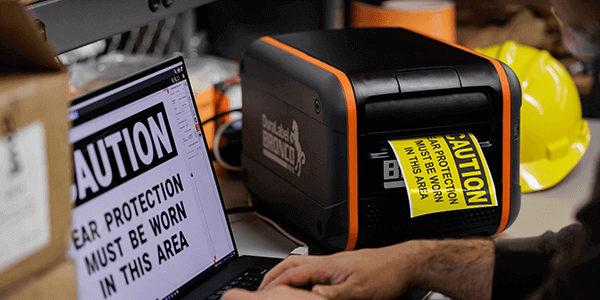

The Solution

By switching to DuraLabel Premium Vinyl Labels, IPG Photonics built a more dependable and professional product identification process. The labels are now used across multiple departments to:

- Print Long-Lasting Product IDs: Labels adhere securely the first time and maintain a clean, professional look.

- Resist Oil & Handling Wear: Materials are engineered for harsh industrial environments, standing up to oils, moisture, and frequent contact.

- Expand Usage Across Teams: Ideal for safety, product ID, and general labeling across diverse workflows.

- Reduce Label Failures: Eliminate reprints and manual fixes caused by peeling, fading, or smudging.

We were exploring other options, but we were not satisfied with their final product. — Michael Hoffman

The Results

Today, IPG Photonics relies on DuraLabel Premium Vinyl Labels to deliver clean, professional, and highly reliable identification across their production floor. The labels hold fast in challenging manufacturing conditions—resisting oils, handling wear, and environmental stressors—while maintaining a sharp, legible appearance.

The difference in performance was clear: fewer labeling errors, less rework, and smoother operations across departments.

Solve your toughest adhesion and durability challenges—explore DuraLabel Premium Vinyl Labels for labeling that performs from production to delivery.

.png)

.png)