Industry

Oil & Gas

Challenge

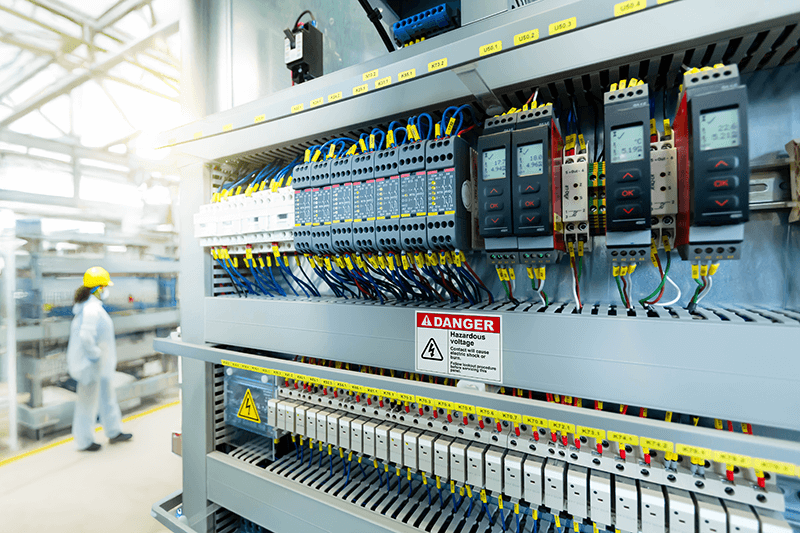

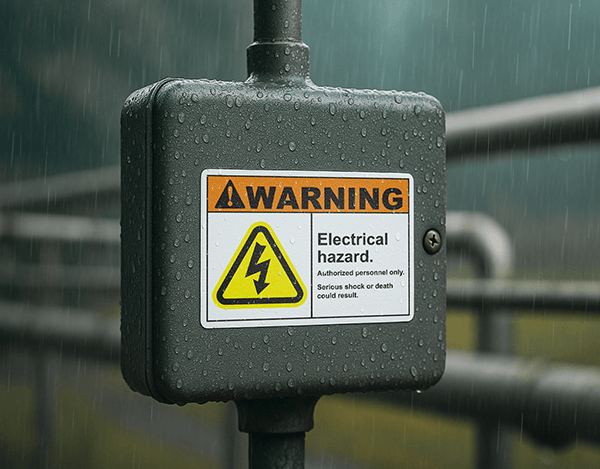

Williams needed durable, weather-resistant labels that could withstand harsh outdoor conditions. Previous labeling methods—including traditional adhesive labels and metal tags—frequently failed by peeling, fading, rusting, or becoming illegible after a short time. As a result, field teams struggled to quickly identify assets like valves, pipes, and electrical hazards, disrupting maintenance workflows and compliance efforts.

Results

With DuraLabel’s outdoor-grade labeling solutions, Williams made asset identification easier and more reliable across their pipeline operations. Labeling valves, pipes, and electrical hazards with durable materials has improved safety, ensured compliance, and simplified field navigation for maintenance crews.

Key Product

"Your products are essential to being able to identify assets in the field."

Alex Eastman

- Identify Valves, Pipes, and Electrical Hazards Quickly: Field teams can now locate assets across the pipeline network with ease.

- Ensure Long-Term Durability in Harsh Conditions: Labels remain intact and legible through rain, snow, heat, and UV exposure.

- Reduce Costs by Replacing Costly Metal Tags: DuraLabel’s materials outperform metal tags at a lower cost.

- Improve Compliance and Safety: Clear, accurate labeling supports proper procedures and safe navigation during fieldwork.

-

Standardize Labeling Across Teams: Consistent labeling practices across departments enhance clarity and reduce training time.

"Labels not being legible after a short period of time or not sticking to our assets—those were major issues. Your products hold up very well to outdoor weather." – Alex Eastman

The Results

Today, Williams depends on DuraLabel’s field-tested labeling solutions to maintain clarity and consistency across its pipeline infrastructure. The ability to clearly identify assets has strengthened safety protocols, reduced confusion in the field, and ensured that maintenance teams can operate efficiently—regardless of the weather.

With durable outdoor labels in place, the company continues to build on its commitment to safety, compliance, and reliable operations.

Discover why DuraLabel is different by watching how we tough-test our labels.

.png)