Harsh Environment Labeling FAQ

Labeling Solutions for Harsh and Demanding Environments

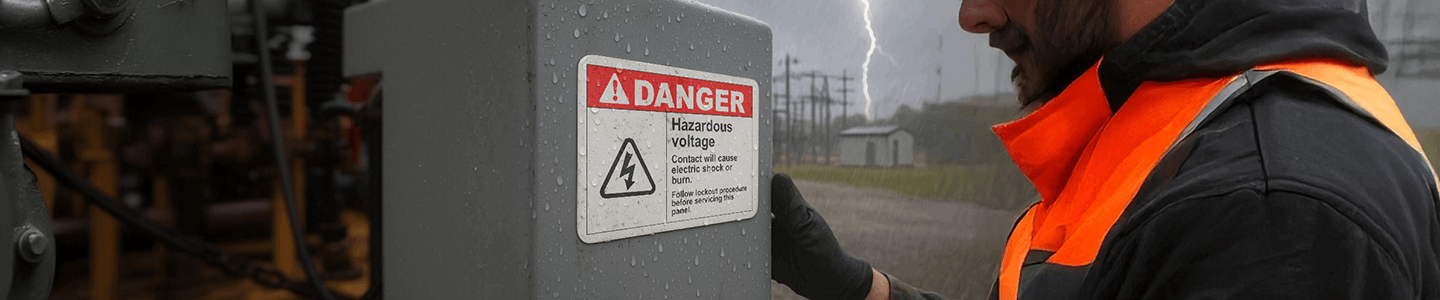

Industrial and outdoor environments often expose labels to extreme heat, cold, chemicals, and abrasion. Selecting the right materials and adhesives is essential for labels to remain legible and secure under these harsh conditions. Durable labeling supports safety, compliance, and efficient operations—even in the toughest settings.

Topics Covered:

Learn how to choose labels that can withstand demanding environments.

- Material Selection: Which materials hold up best against temperature swings, chemicals, and wear.

- Adhesive Performance: How to ensure labels stay put on difficult surfaces.

- Compliance Considerations: Meeting OSHA and industry-specific requirements in harsh conditions.

Explore these resources to improve reliability and compliance in challenging work environments.

Harsh Environment Labeling Frequently Asked Questions

- Are there labels that can withstand exposure to UV light and outdoor conditions?

- How can I ensure labels adhere to oily or dirty surfaces?

- What industries require specialized labeling for harsh conditions?

- What labeling solutions are available for marine or underwater applications?

- What materials are best for labels in high-temperature environments?

Explore our extensive FAQ library to get insights on industrial labeling, workplace safety, and compliance. Find solutions and best practices for maintaining a safe and efficient work environment.

Related Resources

Equipment Labeling Best Practices FAQ

Equipment Labeling Standards for Safety and Compliance This section explains best practicesfor labeling ...

Read

Custom Labels FAQ

How to Create Custom Labels That Meet Compliance Standards Compliance labeling isn't one-size-fits-all. Many ...

Read

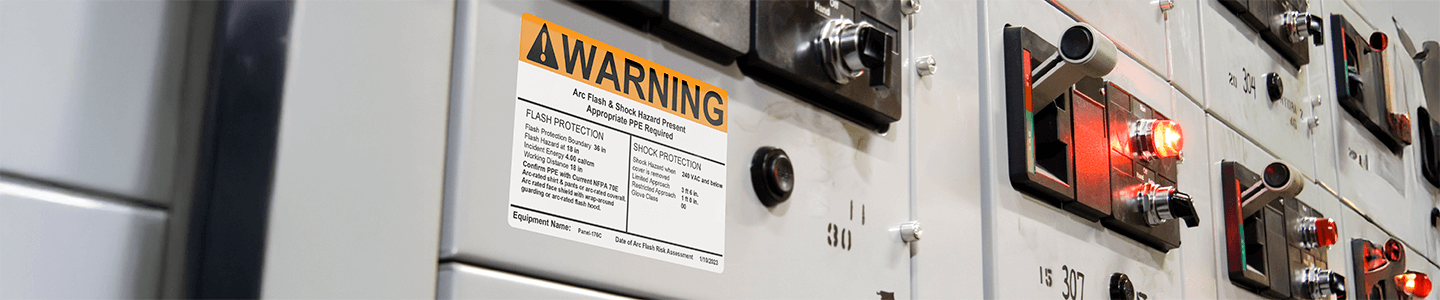

Arc Flash Labeling FAQ

Arc Flash Labeling Requirements Under NFPA 70E This section explains the labeling requirements for arc flash ...

Read.png)