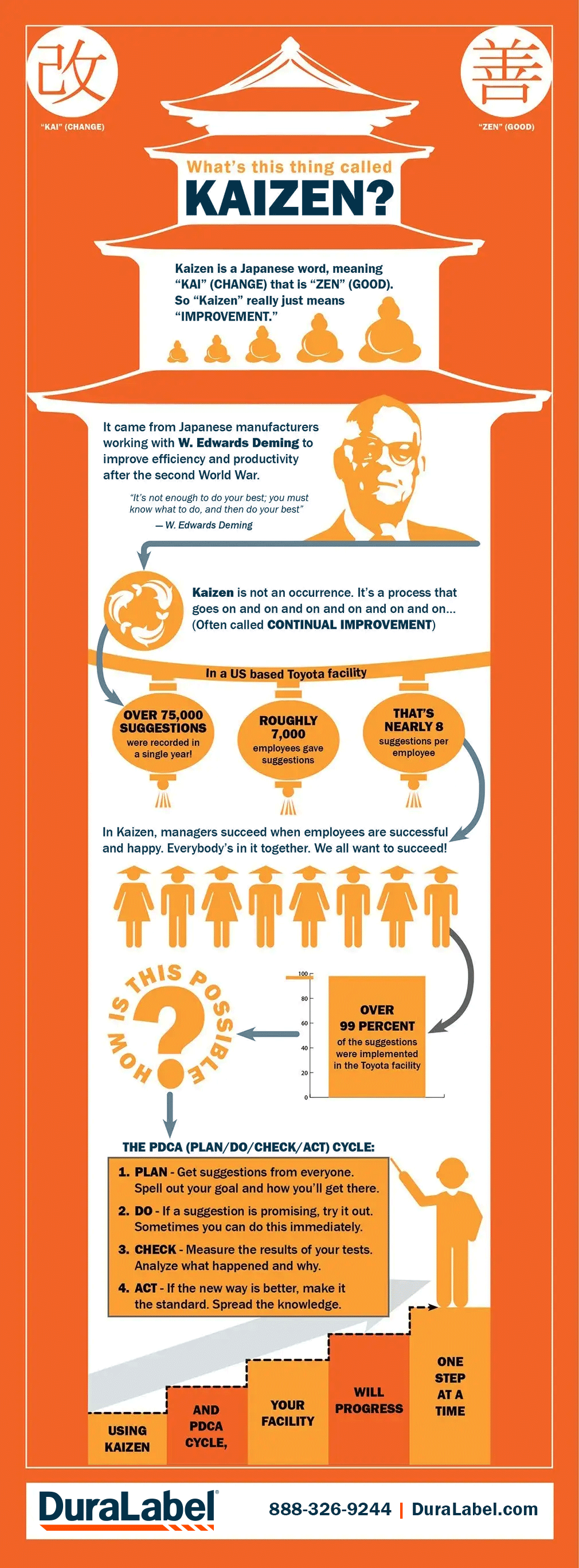

What’s this thing called

KAIZEN?

Infographic Transcription

改 “KAI” (CHANGE)

善 “ZEN” (GOOD)

Kaizen is a Japanese word, meaning “KAI” (CHANGE) that is “ZEN” (GOOD). So “Kaizen” really just means “IMPROVEMENT.”

It came from Japanese manufacturers working with W. Edwards Deming to improve efficiency and productivity after the second World War.

“It’s not enough to do your best; you must

know what to do, and then do your best”

— W. Edwards Deming

Kaizen is not an occurrence. It’s a process that goes on and on and on and on and on and on…

(Often called CONTINUAL IMPROVEMENT)

In a US based Toyota facility

OVER 75,000 SUGGESTIONS were recorded in a single year!

ROUGHLY 7,000 employees gave suggestions

THAT’S NEARLY 8 suggestions per employee

In Kaizen, managers succeed when employees are successful and happy. Everybody’s in it together. We all want to succeed!

HOW IS THIS POSSIBLE?

OVER 99 PERCENT of the suggestions were implemented in the Toyota facility

THE PDCA (PLAN/DO/CHECK/ACT) CYCLE:

- PLAN - Get suggestions from everyone.

Spell out your goal and how you’ll get there.

- DO - If a suggestion is promising, try it out.

Sometimes you can do this immediately.

- CHECK - Measure the results of your tests.

Analyze what happened and why.

- ACT - If the new way is better, make it

the standard. Spread the knowledge.

USING KAIZEN AND PDCA CYCLE, YOUR FACILITY WILL PROGRESS ONE STEP AT A TIME

DuraLabel®

888-326-9244 | DuraLabel.com

.png)

%20(1)%20(2)%20(1).webp)