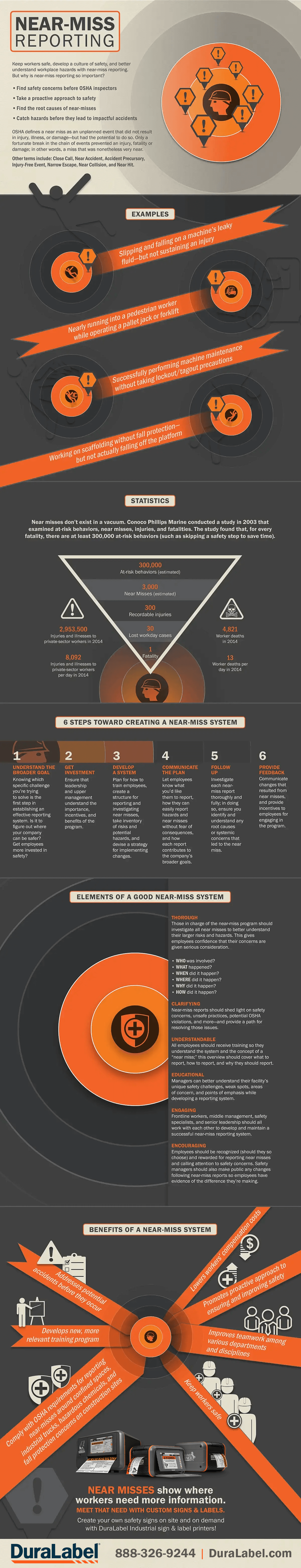

NEAR-MISS REPORTING

Infographic Transcription

Keep workers safe, develop a culture of safety, and better understand workplace hazards with near-miss reporting.

But why is near-miss reporting so important?

• Find safety concerns before OSHA inspectors

• Take a proactive approach to safety

• Find the root causes of near-misses

• Catch hazards before they lead to impactful accidents

OSHA defines a near miss as an unplanned event that did not result in injury, illness, or damage—but had the potential to do so. Only a fortunate break in the chain of events prevented an injury, fatality, or damage; in other words, a miss that was nonetheless very near.

Other terms include: Close Call, Near Accident, Accident Precursory, Injury-Free Event, Narrow Escape, Near Collision, and Near Hit.

EXAMPLES

Slipping and falling on a machine’s leaky fluid—but not sustaining an injury

Nearly running into a pedestrian worker while operating a pallet jack or forklift

Successfully performing machine maintenance without taking lockout/tagout precautions

Working on scaffolding without fall protection—but not actually falling off the platform

STATISTICS

Near misses don’t exist in a vacuum. Conoco Phillips Marine conducted a study in 2003 that examined at-risk behaviors, near misses, injuries, and fatalities. The study found that, for every fatality, there are at least 300,000 at-risk behaviors (such as skipping a safety step to save time).

300,000

At-risk behaviors (estimated)

3,000

Near Misses (estimated)

300

Recordable Injuries

30

Lost workday cases

1

Fatality

2,953,500

Injuries and illnesses in private sector workers in 2014

8,092

Injuries and illnesses in private sector workers per day in 2014

4,821

Worker deaths in 2014

13

Worker deaths per day in 2014

6 STEPS TOWARD CREATING A NEAR-MISS SYSTEM

1

UNDERSTAND THE BROADER GOAL

Knowing which specific challenge you’re trying to solve is the first step in establishing an effective reporting system. Is it to figure out where your company can be safer? Get employees more invested in safety?

2

GET INVESTMENT

Ensure that leadership and upper management understand the importance, incentives, and benefits of the program.

3

DEVELOP A SYSTEM

Plan for how to train employees, create a structure for reporting and investigating near misses, take inventory of risks and potential hazards, and devise a strategy for implementing changes.

4

COMMUNICATE THE PLAN

Let employees know what you’ll do when they report, how they can easily report hazards and near misses without fear of consequences, and how each report contributes to the company’s broader goals.

5

FOLLOW UP

Investigate each near-miss report thoroughly and talk it out. In doing so, ensure you identify and understand any root causes or systemic concerns that led to the near miss.

6

PROVIDE FEEDBACK

Communicate changes that resulted from near misses, and pass job incentives to employees for engaging in the program.

ELEMENTS OF A GOOD NEAR-MISS SYSTEM

THOROUGH

Those in charge of the near-miss program should investigate all near misses to better understand their larger risks and hazards. This gives employees confidence that their concerns are given serious consideration.

• WHO was involved?

• WHAT happened?

• WHEN did it happen?

• WHERE did it happen?

• WHY did it happen?

• HOW did it happen?

CLARIFYING

Near-miss reports should shed light on safety concerns, unsafe practices, potential OSHA violations, and more—and provide a path for resolving those issues.

UNDERSTANDABLE

All employees should receive training so they understand the system and the concept of a “near miss.” This overview should cover what to report, how to report, and why they should report.

EDUCATIONAL

Managers can better understand their facility’s unique safety challenges, weak spots, areas of concern, and points of emphasis while developing a reporting system.

ENGAGING

Front line workers, mid-level management, safety specialists, and senior leadership should all work with each other to develop and maintain a successful near-miss reporting system.

ENCOURAGING

Employees should be recognized for what they do (because all are motivated for reporting near misses and calling attention to safety concerns). Safety managers should also make policy or changes following near-miss reports so employees have evidence of the difference they’re making.

BENEFITS OF A NEAR-MISS SYSTEM

Addresses potential accidents before they occur

Develops new, more relevant training program

Comply with OSHA requirements for reporting near-misses around confined spaces, industrial trucks, hazardous chemicals, and fall protection concerns on construction sites

Lowers workers’ compensation costs

Promotes proactive approach to ensuring and improving safety

Improves teamwork among various departments and disciplines

Keep workers safe

NEAR MISSES show where workers need more information.

MEET THAT NEED WITH CUSTOM SIGNS & LABELS.

Create your own safety signs on site and on demand with DuraLabel Industrial sign & label printers!

DuraLabel 888-326-9244 DuraLabel.com

.png)