The Survivor's Guide to Arc Flash Injury Safety

What Can Workers Learn from an Arc Flash Survivor’s Story?

On Thursday, August 12, 2004, electrical contractor Donnie Johnson's day began like any other. However, the looming threat of Hurricane Charlie in Tampa, Florida, added a sense of urgency to his work. Donnie's task was to wire a large semi-trailer mounted generator to a massive frozen foods warehouse electrical system in preparation for the storm.

During this process, in a mere moment, Donnie experienced a devastating arc flash incident. He suffered third-degree burns down to the muscle on both arms and hands, along with second-degree burns to his face, head, and neck. The intense heat of the blast seared through him, reaching temperatures as hot as seven times that of the sun's surface, as indicated by burn unit doctors. His wife could only identify him at the accident scene by recognizing his boots near his stretcher in the ambulance.

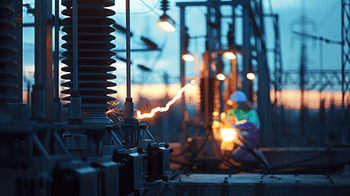

What is an Arc Flash Accident?

"As I was being blown to the ground I actually saw a two to three foot ball of white light, or basically a ball of lightning." – Donnie Johnson

An arc flash is a sudden release of electrical energy, resulting in a violent explosion that emits extreme heat and light rapidly. OSHA regulations advise individuals engaged in electrical tasks to put on protective gear that resists ignition during such incidents. These flashes may not always happen spontaneously; they can be triggered by contact with tools or the presence of conductive dust or corrosion.

Safety Tips From a Arc Flash Survivor

Donnie knows that he was lucky to survive his arc flash injury. An arc flash incident can be deadly. His experience underscores the importance of prevention, training, and following procedures without compromise. Here are some tips from Donnie to help prevent similar incidents in the future:

- Prioritize Personal Protective Equipment (PPE): Always wear proper arc flash PPE when working with electrical systems, including arc flash suits, gloves, and face shields. Don't underestimate the importance of protective gear, as it could have prevented many severe arc flash injuries.

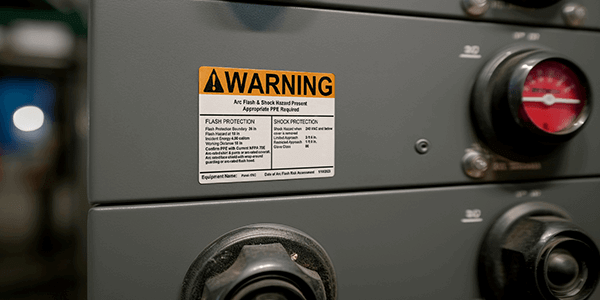

- Read Warning Labels: Take warning labels seriously and follow instructions meticulously. If I had read the arc flash warning label on the equipment I was using, indicating it shouldn't be used on live circuits, I could have avoided the arc flash explosion.

- Embrace Safety Procedures: Follow established safety protocols without exception. Even if a task seems routine or harmless, adhere to safety guidelines rigorously. Taking shortcuts or neglecting safety procedures can have catastrophic consequences.

- Stay Vigilant Around Electrical Equipment: Be aware of potential hazards and exercise caution when working with electrical systems. Even a momentary lapse in attention can lead to accidents. Stay focused and alert to minimize the risk of arc flashes or other electrical incidents.

- Continuous Training and Awareness: Regularly update your knowledge of electrical safety practices and stay informed about industry standards. Participate in training sessions and safety seminars to reinforce good habits and prevent complacency in the workplace.

Donnie acknowledges that his severe arc flash injuries had been preventable if only he followed safety procedures by wearing proper arc flash PPE. An electrician of nearly two decades, Donnie miraculously survived and now devotes a big part of his life to telling his story in hopes of saving lives by advocating for the importance of safety.

"This is about my personal experiences before, during and since the accident. Also how it affects you and those who care about and depend on you, all of this happened because I wasn't wearing my safety gear," says Donnie.

He also neglected to read the arc flash warning label on the motor rotation meter he was using, stating it was not to be used on live circuits. He checked the electrical rotation on the 480 volt generator, fully energized to get an accurate reading. He opened the electrical cabinet panel, connected the first two clips, but when attempting to clip the third, the meter failed and blew a puff of carbon into the electrical gear.

His surgeries and recovery lasted almost two years, and as he mentions repeatedly on his website, all because he didn't take less than a minute to put on his arc flash PPE.

Life After an Arc Flash Explosion

After completing two years of rehabilitation, Donnie returned to work at Borrell Electric Company's office in early 2006, where he has been employed for over two decades. He and his wife are actively involved in promoting workplace safety across the United States through the dissemination of Donnie's Accident video, which has become a widely recognized tool for safety training worldwide.

Reflecting on his newfound recognition, Donnie expressed pride in knowing that safety managers worldwide incorporate his video into their employee training programs. Despite comprehensive safety training, Donnie acknowledges the challenge of combating complacency in the workplace. He hopes to make a meaningful impact by raising awareness and inspiring others to prioritize safety. While accidents are inevitable, Donnie emphasizes the importance of adhering to safety procedures and wearing proper arc flash PPE to mitigate risks. He acknowledges that his experience serves as a cautionary tale and underscores the critical role of safety measures in preventing severe arc flash injuries.

How Common Are Arc Flash Injuries?

In the U.S, there are an average:

- 30,000 arc flash incidents

- 7,000 burn injuries

- 2,000 hospitalizations

- 400 fatalities

According to the Center of Disease Control (CDC), electrocution ranks as the fifth leading cause of workplace fatalities in the U.S. Shockingly, one to two arc flash-related fatalities occur daily across North America. Considering the relatively small number of electricians in the workforce, this statistic is particularly concerning.

An arc flash incident doesn't always coincide with an electric shock. Either can happen independently. Many electricians have experienced shocks (some even more than 10 times in their careers), yet they don't always exhibit horrific burns. The shock and the arc flash may not occur simultaneously. Every 30 minutes, a worker suffers an electrically induced injury that requires time off the job for recovery.

Protect Your Workers from Arc Flash Injuries

While OSHA 1910.333 emphasizes working on de-energized parts, some believe that current regulations lack the necessary enforcement to address arc flash concerns. The NFPA 70E standard provides practical safeguards for electrical safety but is often referenced by OSHA only after incidents occur. Companies must take important safety steps:

- Ensure workers receive "Qualified Worker" training covering NFPA 70E standards.

- Conduct a proper Arc Flash Risk Assessments

- Label all electrical panels with compliant arc flash warning labels

Reinforce Arc Flash Protection Through Visual Communication

Visual communication tools are not just decorative; they are vital assets in preventing an arc flash hazard. While Donnie's injuries were electrical, various professions, from plumbers to carpenters to masons, depend on visual cues to alert them to arc flash or LO/TO (Lockout/Tagout) dangers. Clear and concise labeling of electrical equipment is essential. An arc flash warning label provides critical information about potential hazards, including:

- Arc flash boundary: The minimum safe distance from energized equipment during an arc flash event.

- Arc flash PPE requirements: Indicating the necessary gear for working near specific equipment.

- Incident energy levels: Quantifying the potential severity of an arc flash.

Floor boundary markers define safe zones around electrical panels, switchgear, and other high-risk areas. These markers help workers understand where they should stand to minimize exposure during maintenance or troubleshooting.

Color-coded floor markings indicate different safety zones:

- Green: Safe zone for normal operations.

- Yellow: Caution zone, approach with care.

- Red: Restricted area, only authorized personnel allowed.

Highly visible signs near electrical equipment serve as reminders and warnings. "Danger: Arc Flash Hazard" signs should be placed at arc flash boundary points. "Lockout/Tagout" signs remind workers to de-energize equipment before maintenance. "Emergency Shutdown" signs identify emergency procedures. Consistent use of safety signage reinforces safety protocols and keeps workers vigilant. Above all, it is important to encourage a safety culture where everyone actively looks out for visual cues and follows established protocols.

DuraLabel Arc Flash Injury Prevention Solutions

Every arc flash survivor story is a reminder of what’s at stake — and how much can be prevented through preparation. A strong safety culture, clear labeling, and consistent training protect not just individual workers, but entire crews.

Easily design and print arc flash and electrical safety labels any time you need them, onsite or in the field with the versatile DuraLabel® Kodiak Max Industrial Sign and Label System. This printer also serves as an excellent facility-wide industrial labeling system to print signs and labels for all kinds of applications and environmental conditions indoors and out. To reinforce safety, design an electrical safety training program. NFPA 70E training remains the best option for worker safety and compliance, helping to contribute to a workplace culture of safety.

To enhance your program further, download the free arc flash labeling quick start guide . It's important to periodically evaluate your facility for electrical safety and ensure all arc flash labels are up to date to keep workers safe and your facility operating smoothly.

Want to learn more about arc flash PPE? Our free Arc Flash PPE Chart explains the four types of arc flash categories, lists minimum arc rating (AR) and required arc flash clothing for each situation.

Get help crafting a system that will provide the safety communication you need. Call 1-888-902-2148 and one of our experts will guide you through the process.

Read next:

Related Resources

What Is An Arc Flash?

An arc flash is an explosive burst of heat and light, caused by a sudden, uncontrolled electrical arc (or ...

Read

Create a Safer Facility with a Proper Arc Flash Boundary

What Is the Arc Flash Boundary? NFPA 70E is the major industrial standard for safe electrical work in the ...

Read

Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary? An arc flash protection boundary defines the minimum safe distance ...

Read.png)