The Advantages of Lean Manufacturing: 5S, Kaizen, and TPM in Action

What Are the Advantages of Lean Manufacturing?

Womack and Jones, in their book Lean Thinking, define lean manufacturing as "a systematic approach to identifying and eliminating waste." When properly implemented, the advantages of Lean manufacturing go beyond cost savings—they include better flow, faster output, and stronger quality control. Whether you're applying 5S, Kaizen, or TPM, each tool drives Lean efficiency improvements by cutting waste, reducing errors, and maximizing equipment uptime.

These benefits of Lean processes show up in faster order processing, less downtime, and stronger team collaboration. With the right tools and mindset, companies can unlock measurable results—making Lean a proven path to sustainable growth.

Create Flow

Lean manufacturing can help create flow through process and visual design. Every factor (buildings, people, equipment, materials, and processes) must be carefully examined so that workflow can be optimized. 5S can help improve workflow by:

Lean manufacturing can help create flow through process and visual design. Every factor (buildings, people, equipment, materials, and processes) must be carefully examined so that workflow can be optimized. 5S can help improve workflow by:

- Removing unnecessary tools, supplies, and equipment to increase the available work area and storage space (Sort)

- Organizing tools, supplies, and workstations in a manner that will improve efficiency and make it easier to move from one task to the next (Set in Order)

- Cleaning the workplace to make it easier to spot leaks, material buildup (metal shavings and dust), and other signs that equipment may not be working properly (Shine)

- Applying consistent improvements from Sort and Set in Order throughout the workplace (Standardize)

- Continuing to review and improve workflow by practicing each step in 5S (from Sort to Sustain) on a daily basis (Sustain)

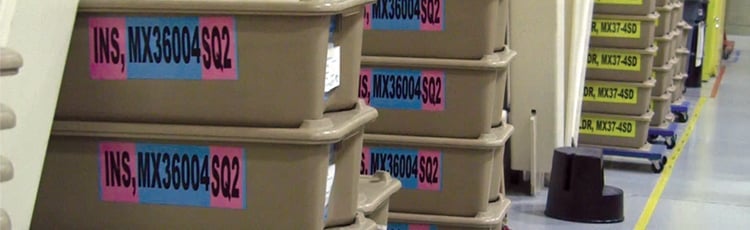

Throughout the process, visual design (signs, labels, wayfinding, and floor marking) can support 5S:

- Mark tools with department information, numbers, and barcodes to improve tracking and remind workers where items belong.

- Use color coding to distinguish one department from another. This will help ensure that workers can quickly navigate their workplace and identify their area of responsibility.

- Use DuraLabel® PathFinder® Floor Marking Products to identify places for equipment, mark traffic lanes (powered vehicle vs. pedestrian lanes), and help people identify departments and work zones.

- Place signs in strategic locations to communicate common maintenance practices as well the tools needed to perform maintenance or assembly. This will make it easier for workers to follow standards and ensure that they have the tools they need to perform their work.

When used together, these visuals form a comprehensive system that enables people to quickly move through the workplace, identify procedures, locate equipment, and replace equipment at the end of the day. Learn more about 5S and how it can improve workflow, increase efficiency, and reduce costs with the in-depth 5S System Best Practice Guide.

Remove Waste

Reducing waste is one of the key aspects of lean manufacturing, and tools like Kaizen and TPM can help businesses find and eliminate waste throughout the workplace. Waste takes many forms including:

Reducing waste is one of the key aspects of lean manufacturing, and tools like Kaizen and TPM can help businesses find and eliminate waste throughout the workplace. Waste takes many forms including:

- Time spent waiting

- Overly complicated procedures

- Defects or errors created by processes or equipment

Removing Waste with Kaizen

Kaizen's strength comes from understanding that workers are in the ideal position to recognize areas and processes that can be improved. Encourage workers to look for wasteful practices and make suggestions on eliminating the source of waste. Workers can provide suggestions directly to their supervisors, through suggestion boxes, during standup meetings, or by using Kaizen boards.

To help get things started, set specific goals such as looking for ways to increase order processing efficiency and looking for processes that have unneeded steps.

Provide continuous support to ensure that good ideas are acted upon and that Kaizen becomes part of the workplace culture. Once employees see how Kaizen can improve the workplace and make their work easier, new ideas for improvements will surge.

An excellent example of reducing waste with Kaizen comes from a company based in Commerce City, California. Workers identified a problem with the invoicing system. On average, there were 700 incomplete orders at any given time, which significantly reduced revenue. In response, the sales team helped to develop a system that would not allow incomplete orders to be put into the system. This ensured that every future order had the information needed to be processed-reducing time spent hunting down missing information and eliminating waste.

(Source: Imai, M. (2012). Gemba Kaizen)

Our in-depth Kaizen & PDCA Best Practice Guide provides more examples and valuable tips on how Kaizen can be used to solve problems, reduce costs, and improve quality.

Removing Waste with TPM

Idle and malfunctioning equipment is a significant source of waste for many businesses. Ineffective maintenance causes equipment to break down, resulting in unproductive periods of downtime.

TPM helps to reduce equipment breakdowns through its Eight Pillars. Operators perform daily maintenance on the equipment they work with and report problems to the maintenance department. The maintenance department, in turn, addresses problems before they cause equipment to break down. When the equipment does break down or produce defective products, the cause is eliminated by updating preventive maintenance programs, investing in new equipment, and by providing additional training as needed.

Implement TPM in your facility today. Learn how each pillar helps to achieve the three goals of TPM, creating a leaner facility:

- Zero unplanned downtime

- Zero product defects

- Zero accidents

Take Action Today

Want to implement the advantages of Lean manufacturing in your facility? Call us today at 1-888-788-9936. One of our experts will help you integrate Lean efficiency improvements like 5S, Kaizen, and TPM into your workflow using proven DuraLabel visual communication tools.

Related Resources

Lean Facility

Creating a Lean Facility The global market places significant pressure on businesses and other organizations ...

Read

Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter? Lean manufacturing principlesare core ...

Read

How to Improve Quality Control in Manufacturing with Lean and 5S

What Is Quality Control in Manufacturing and Why Does It Matter? In manufacturing, quality control is a ...

Read.png)