The Toyota Production System (TPS) is a foundational framework for TPS and Lean Manufacturing, designed to reduce waste, improve quality, and empower workers. Its core principles—including Kaizen and TPS, Just-in-Time, and 5S—drive workflow optimization and continuous improvement in every aspect of production.

Toyota's lean production system has transformed the manufacturing industry. David Landes, an economic historian from Harvard describes it as the most important technical innovation since Ford's successful implementation of the moving assembly line.

The Toyota Production System (TPS) is the culmination of the company's dedication to continuous improvement. It is the culture adopted by employees and management alike. In the Toyota Production System, each person follows the same set of principles, which focus on improving production processes based on the customer's need and the product's quality, as well as safety in the plant and on the road.

Advantages of the Toyota Production System

The Toyota Production System provides numerous advantages for those who choose to implement it as a means of improving their current production system. The system uses continuous improvement to empower businesses by creating a culture that entrusts employees with key responsibilities at each stage of production. Employees become central in discovering problems and solving them.

TPS improves quality in products and processes. Overall, TPS uses several lean methods to help reduce errors and improve quality: Kaizen, 5S, 5 Whys, and Poka-Yoke. These tools help workers spot inefficiencies, errors, or potential defects and empower them to stop the assembly line so that defects are not included in the final product.

TPS reduces waste, increasing efficiency and reducing costs. The high-quality and cost-competitive products Toyota produces are directly linked to Toyota's ability to reduce waste throughout the production process. Just-In-Time (JIT), Kanban, Taki-Time, and Kaizen are used to spot waste. Areas that have wasted movement, overproduction, underproduction, inefficient transportation, unnecessary inventory, and defects are identified and improved until waste is eliminated.

TPS improves customer satisfaction by providing products that are free of defects. TPS succeeds because it puts the customer first. The company's zero-defect policy and continuous effort to reduce costs enables the company to deliver quality at a price customers can afford.

TPS improves all aspects of safety for employees and customers. TPS is a safety-conscious system that works to reduce risks in the workplace as well as those found on the road. 5S helps employees spot and eliminate hazards, while Kaizen enables employees to stop the production line and eliminate errors that may increase risks while driving.

stop the production line and eliminate errors that may increase risks while driving.

How Is Lean Related To The Toyota Production System?

The various tools, practices, methods, and techniques developed as a part of the Toyota Production System have come to be collectively called "lean manufacturing" or simply just "lean." Why lean? Because the Toyota Production System focuses on eliminating waste and doing just those things that deliver value a customer is willing to pay for. That makes for a lean operation, with little fat (waste).What are these tools, practices, methods, and techniques?

They include:

- 5S: Cleaning up to make problems visible and getting organized.

- Kaizen: Continuous improvement through acting on suggestions.

- Kanban: Demand pulls products through the production process, resulting in a just-in-time system of inventory and production.

- Poka-Yoke: Mistake proofing.

- TPM (Total Productive Maintenance): Proactive and preventative maintenance done in a way that maximizes the productive operation of machines and equipment.

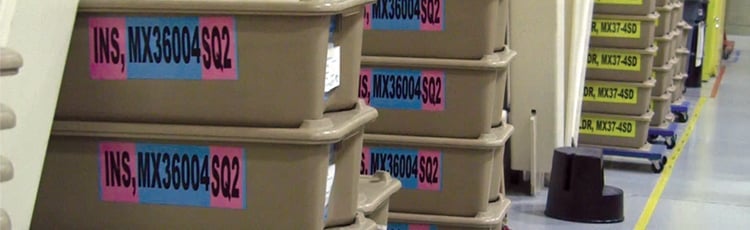

- Visual Factory: Using visual labels, signs, tags, and other cues to improve communication.

What Does The Toyota Production System Accomplish?

Toyota states on their web site that their goals for the Toyota Production System are:

To provide the customer with the highest quality vehicles, at lowest possible cost, in a timely manner with the shortest possible lead times. To provide members with work satisfaction, job security and fair treatment. It gives the company flexibility to respond to the market, achieve profit through cost reduction activities and long-term prosperity. These benefits result from eliminating the three types of waste:

- Muda: wasteful actions

- Muri: unevenness (lack of uniformity)

- Mura: excessive burden or stress

The goal is to eliminate waste to as great an extent possible, and then standardize on the procedures, processes, work practices, designs, and methods that resulted in the minimum amount of waste.The foundation of all of the lean tools is standardization. Standardization is used to ensure changes, implemented through the use of lean tools, continue to be used. In addition, standardization helps to ensure safe work practices and quality products.Let's take a look at three of the main Toyota Production System tools.

Toyota Production System and Continuous Improvement

Kaizen is the key tool that makes the Toyota Production System so effective. Without Kaizen, the Toyota Production System would have no foundation. The principle behind Kaizen is to always be improving.

These are not necessarily big capital project types of improvements, but small incremental improvements. The word "Kaizen" literally means continuous improvement.

Kaizen works by encouraging suggestions that are used to continuously make small improvements. The suggestions typically come from those who are the closest to the areas needing to be improved, such as equipment operators, warehouse workers, and people processing purchase orders. Although suggestions may also come from customers and suppliers.

The way Kaizen works is based on employees having the responsibility to follow the established standard procedures, and to also look for ways to improve those standards. They submit suggestions for improving the standards, and those suggestions are quickly acted on by supervisors and managers.

That does not mean all suggestions are approved, but it means that suggestions do not languish for long periods of time waiting for a manager to review them.

The result is a continuous stream of small changes that result in ongoing improvements. Because the changes are small, they can be quickly and economically implemented. Because they are continuous, over a short period of time they'll add up to significant improvements.

Just-In-Time

Excessive inventory is waste. The cost of that inventory, and the cost of storing it and maintaining it, are major costs that can be eliminated.

By using a system that uses customer demand to stimulate production, inventory can be reduced to a minimum. This system is called "just-in-time," and Kanban is the tool that provides an effective just-in-time system.

Kanban is a system of visual "signals" that indicate there is a demand for something. Let's look at a simple example: manufacturing a product called a widget.

A widget is made using three parts: a case, a stem-bolt, and a gauge. The widget assembly area has three bins, one for each of the three parts. When an order comes in, the widget assembly area starts assembling widgets. When one of the parts bins becomes empty, a card, called a Kanban, is sent to the appropriate area signaling that more of that part is needed.

Thus, products and their component parts are only made when they are needed, as indicated by a Kanban card.

This process requires that the sending of the Kanban be timed such that the widget assembly process does not run out of parts, and it requires some flexibility in worker capability. For example, if orders for widgets slow down, but orders for self-activating gizmos increase, the workforce needs to be flexible enough to handle the change in production.

Just-in-time delivery—and Kanban—have more advantages than just reducing inventory costs. For example, with lean inventories, if a new design is developed, it can start shipping almost immediately because there is no inventory of older widgets that need to be sold first.

Another advantage of Kanban is that if there’s a quality problem, you won’t end up with a warehouse full of defective widgets. The problem can be identified quickly and fixed before it has a major impact.

Visual Factory

Not only does Kanban use a system of visual signals to control production, the entire Toyota Production System is based on visual communication. Why visual communication? Visual communication is the most effective means of communication.

People understand the message quicker, and with greater comprehension, than any other means of communication. In addition, in a manufacturing setting different information needs to be communicated simultaneously to multiple people. Using other means of communication, such as sounds, would result in confusion and a cacophony of noise.

What Is Visual Communication?

Visual communication uses color, shapes, symbols, pictograms, and text to communicate needed information. Some visual communication, such as safety signs, are required by OSHA. Other forms are used to improve productivity, ensure quality, and provide essential guidance in the workplace.

Visual communication is as simple as using floor marking tape to keep forklifts and pedestrians separated. It can be as easy as color-coded tool storage with shadow boards—or as complex as start-up and shutdown procedures posted on machines using instructional labels.

Signs are used to direct people to their destinations, identify storage locations, and notify them about shared expectations—like placing 50 cents in the cup to help pay for the morning coffee. Tags mark valves and switches that are locked out. Labels identify pipes and wiring. Stickers on hard hats identify personnel roles or clearances.

Visual communication is all around us, providing the information we need. Where does it come from? In many cases, from DuraLabel® Industrial Sign and Label Systems using tough-tested supplies. DuraLabel offers the right materials for all the visual communication methods mentioned here—from floor marking tape to more than 50 types of labeling supplies.

Take Action Today

If learning about the Toyota Production System has inspired you to take action and make improvements at your organization, then check out our free

Kaizen and PDCA Best Practice Guide or c

all us today at 1-888-788-9936. One of our exper

ts will help you integrate TPS and Lean Manufacturing into your workflow using proven Lean strategies and DuraLabel industrial labeling tools.

.png)