Lean Manufacturing in the Food Industry

Why the Food Industry is Going Lean

The food industry is vast and serves hundreds of millions of people each year, more than any other industry. The complex industry includes:

-

Agriculture ? livestock, crops, and seafood

-

Manufacturing ? farm and processing equipment, supplies, and construction of facilities

-

Food processing ? manufacturing and preparation of food for markets

-

Food distribution ? transportation and storage of food

-

Food service ? fast food, restaurants, catering, etc.

-

Retail markets ? grocery stores, farmers' markets, etc.

Partially because of its complex nature and because it has arguably the largest consumer base, the food industry is taxed with keeping up with trends, like gluten free and organic products. To make things more difficult, consumers expect products to be fresh, free from defects, and safe for consumption.

To meet these challenges, the food industry has turned to lean manufacturing tools like Value Stream Mapping (VSM) and 5S to keep pace with the needs of consumers as well as improve quality.

Keeping Pace with the Needs of Consumers

VSM is a visual lean tool that helps organizations optimize manufacturing and production. Using these maps, you can analyze your current process, highlight problems, and develop complete solutions to best serve your customers. This is accomplished by mapping out the relationship between all aspects of the process and then identifying problems like waste, defects, and so on. The visual map makes it easier to find problems as well as track improvements as they are implemented.

VSM can help make the needs of consumers obvious. According to an article from the United States National Library of Medicine, VSM helped companies in the food industry identify issues in production, processing, storage, distribution, and food service that resulted in significant waste. For one company, this waste was not simply the loss of goods. It also caused them to lose customers, reducing sales. Using VSM, this company identified production processes that reduced the foods' nutritional value. It became clear that what consumers wanted was changing. Consumers were becoming more health-conscious and valued highly nutritious food. The company saw the need for change and improved their production process to provide a higher quality product-improving their sales by meeting the needs of their customers.

Eliminating Contamination

Another benefit of lean manufacturing is that it can help eliminate contamination in the food industry. Contamination can come from many places, including:

- Food storage ? Many types of food are perishable, should not be mixed with other foods (cross-contamination), or may attract mice and other pests.

- Sanitation ? The cleanliness of tools, equipment, preparation surfaces, and the overall facility is a major factor when it comes to food contamination.

- Preparation ? How food is made, as well as other factors like hand-washing and wearing gloves have a big impact on food safety.

- Packaging ? Different foods have different needs. Some foods are sensitive to light, while others are sensitive to heat. If food items are stored incorrectly, they may develop bacteria or spoil.

To help eliminate food contamination, lean tools like 5S provide a systematic method for improving organization, creating a cleaner environment, and improving how work is done through process improvement.

Request the Best Practice Guide to the 5S System and begin improving your facility's efficiency, organization, and cleanliness. This helpful guide includes checklists, training material and much more to get you started.

Implementing Lean in Food Processing Plant

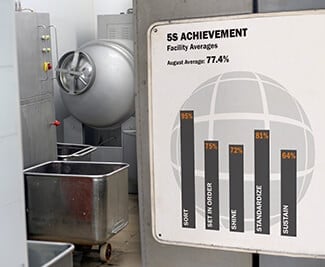

There are many ways you can get started with lean and many tools that you can choose to start with. The 5S system is often selected as the first tool a company implements because of its five powerful steps, which are implemented sequentially:

- Sort-remove unneeded and obsolete items from the workplace. These can include items that do not belong in a given area. For example, if an area is designated for storing ready-to-eat foods, remove any raw meats from the area to reduce contamination.

- Set in Order-organize the workplace based on how work is done. Make sure gloves and other supplies are where workers need them, and place hand-washing stations in easy-to-access locations.

- Shine-clean your facility and equipment to restore them to their original condition. Pay special attention to areas where grease, dirt, and other bacteria might grow.

- Standardize-improve your procedures so things run consistently and efficiently. Make sure that equipment is changed out as needed to reduce cross-contamination and make food safety part of each procedure.

- Sustain-repeat each step every day to ensure your facility remains clean and organized.

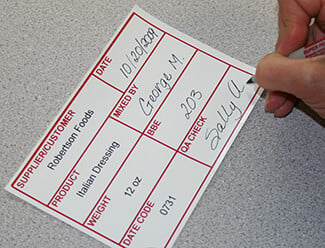

Give your 5S program a boost by implementing labeling and floor marking. Some common uses include:

- Labeling tools so workers know which are for raw foods and which are for ready-to-eat foods

- Marking bins and shelves to let workers know where things belong

- Creating easy-to-follow procedures to help ensure food is properly prepared and stored

- Using floor marking to create designated work areas, safe paths, add extra foot traction, and much more

Reduce your costs, improve quality, and make your workplace more efficient with a free Best Practice Guide to 5S by Duralabel. Download your free copy below.

Related Resources

2 Essential Lean Tools for Establishing New Facilities

Mitigate disruptions and build for the future using a thorough 5S plan from top to bottom. Focus on securing ...

Read

Lean | Not Just Grandpa's Optimization Tool

Lean has been around for decades, but it still has its place as businesses evolve and retain vitality. Big ...

Read

How to Build a 5S Implementation Team for Lean Success

What is a 5S Implementation Team? A 5S implementation team is a group of individuals empowered to make quick ...

Read.png)