Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter?

Lean manufacturing principles are core strategies that drive Lean process improvement by reducing waste and enhancing value. This article explores how waste reduction in Lean is achieved through 5S, value stream mapping, and continuous improvement, helping organizations build efficient, customer-focused workflows.

Where Were Lean Manufacturing Principles for 5S Formed?

The lean manufacturing principles were formed in Japan. In an effort to improve sales and increase profit, Eiji Toyoda embarked on a journey to improve Toyota's manufacturing processes. Inspired by his visit to the Ford facility in Michigan, he collaborated with Taiichi Ohno to develop a series of lean manufacturing tools. Collectively known as the Toyota Production System, these 5S tools gained prominence in James Womack's and Daniel Jones' book, Lean Solutions, where the authors identified the five principles.

The Five Lean Manufacturing Principles in a 5S System

The five lean manufacturing principles are the foundation of Toyota's success and can help businesses create products centered on what customers want. Lean manufacturing centers on the five following principles, but a notable pre-process requirement in the lean 5S system is the formation of a lean team to execute on these principles.

Lean Principle 1: Identify Value

The first of the lean principles, identifying value, is also the first step in the journey to become lean. This step requires businesses to define what customers value and how their products or services meet those values. In this case, value requires:

- Designing products to meet the needs of customers

- Removing features that do not specifically meet those needs

By designing products to meet specific needs, businesses will eliminate wasteful steps that may have been required for unwanted features. Design for Six Sigma (DFSS) is one method that can help businesses identify value. Incorporating 5S principles into the design process ensures that every step is streamlined and focused on adding value. Using Six Sigma Principles and DFSS, companies can systematically define, measure, and analyze what their customers want. Companies can then design products tailored for their customers, with 5S practices enhancing the efficiency and effectiveness of the design process.

Lean Principle 2: Map the Value Stream

The second principle of lean manufacturing is mapping the value stream. A value stream is the complete life-cycle of a product, which includes the product's design, the customers' use of the product, and the disposal of the product.

This step requires companies to identify and map the product's value stream. Lean tools like Value Stream Mapping (VSM) can be used to visually map out the entire product flow. Once the value stream is mapped, it will be easier to find and minimize steps that do not add value.

By gaining a comprehensive view of the product's lifecycle, companies can enhance visibility into their processes, identify inefficiencies, and eliminate non-value-adding activities. Applying 5S practices during this analysis leads to improved operational efficiency, reduced cycle times, and better alignment with customer needs, which results in higher quality products and increased customer satisfaction.

Lean Principle 3: Create Flow

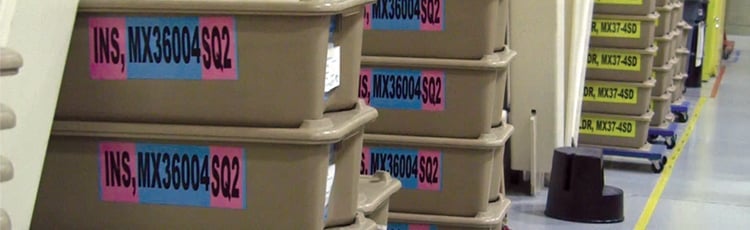

The third lean principle is creating flow. Efficient product flow requires items to move from production to shipping without interruption and can be achieved by strategically organizing the work floor using the 5S system. Every factor, from people and equipment to materials and shipping, must be taken into account to ensure products seamlessly move through the production process.

A well-organized work floor will result in reduced production time, inventory size, and material handling. Creating flow enhances overall operational efficiency by minimizing delays and bottlenecks, which speeds up the production cycle and reduces lead times. It also takes full advantage of resources and space, leading to lower operational costs and improved product quality. Applying lean principles in this context ensures that the production process is optimized and continuously improved.

Lean Principle 4: Establish Pull

.webp)

Closely related to creating flow, the fourth principle of lean manufacturing requires businesses to use a pull-based production system. Traditional production systems use a push system, which starts with purchasing supplies and proceeds by pushing material through the manufacturing process, even when there isn't an order. While push systems are easy to create, they often result in large inventories and a significant amount of work-in-progress (WIP).

A pull system, however, pulls a customer's order from the shipping department, which then prompts new items to be manufactured and signals that additional supplies need to be purchased. Lean manufacturing tools like Kanban can help businesses establish a pull system to control the flow of materials in a production system.

Using a pull system, businesses will:

- Increase output

- Maximize usable workspace

- Reduce inventories

- Eliminate overproduction and underproduction

- Eliminate errors caused by having too much WIP

Companies can create a more responsive and efficient production environment that is better aligned with actual customer demand by adopting a pull system. It also enhances operational agility. This helps businesses adapt quickly to changing market conditions and customer needs.

Lean Principle 5: Seek Perfection

The final lean manufacturing principle requires companies to seek perfection. While seeking perfection may seem straightforward, it is often one of the most difficult principles to successfully apply in the workplace. Seeking perfection requires companies to continuously improve their practices and often requires a shift in the workplace culture.

Kaizen, a philosophy of continuous improvement, can help businesses with this shift by creating a culture where workers seek perfection. Kaizen focuses on making small, incremental changes and requires every worker, from the corner office to the production floor, to help improve business practices.

Over time, Kaizen will result in increased efficiency, lower costs, greater productivity, and better quality products. By embracing Kaizen, companies can implement 5S practices to keep the workplace organized. Visual communication tools can improve clarity and effectiveness. These steps help reduce errors and increase productivity.

DuraLabel Solutions for Lean Manufacturing Principles for 5S

For facilities aiming to effectively implement the 5S system, DuraLabel’s RIGID SIGNAL 5S Floor Marking Tapes offer a practical and durable solution. These high-quality floor marking tapes are designed to support each of the five lean manufacturing principles by providing clear, long-lasting visual cues that help maintain organization and efficiency. These tapes ensure that your workspace remains well-organized and compliant with 5S principles. Invest in DuraLabel’s RIGID SIGNAL 5S Floor Marking Tapes to enhance your lean manufacturing efforts and keep your workplace running smoothly.

Take Action Today

Want to learn more about implementing lean manufacturing principles in your workplace? Our free comprehensive 5S System Quick Start Guide provides the information you will need to start a lean program in your workplace, while infographics, such as The Pillars of TPM, offer guidance on productivity, efficiency, and safety.

Explore all of our free resources or Call 1-888-788-9936 to talk with an expert about Lean process improvement tools like 5S, Kaizen, and value stream mapping. Get Lean 5S working for you today!

Read Next:

Related Resources

Lean Manufacturing Process

What is the Lean Manufacturing Process? The Lean Manufacturing process is a structured lean 5S process for ...

Read

Toyota Production System

What Is the Toyota Production System and Why Does It Matter? TheToyota Production System(TPS) is a ...

Read

How to Improve Quality Control in Manufacturing with Lean and 5S

What Is Quality Control in Manufacturing? Quality control in manufacturing is the process of monitoring and ...

Read.png)