Visual Management Signage That Powers Lean 5S Systems

Why Custom Signs Are Critical for Lean and 5S Implementation

Lean principles prioritize clarity, consistency, and the elimination of waste, and the 5S methodology brings these values to life, step by step. Yet in many workplaces, signage is treated as an afterthought. Generic or inconsistent visuals can undermine otherwise solid systems, leading to confusion, clutter, and compliance risks.

In a true visual workplace, custom signage acts as a silent supervisor. It shows where items belong, reinforces habits, prevents errors, and helps new staff get up to speed quickly. Custom signs aren’t just nice to have. They’re essential for making Lean strategies sustainable and visible long-term.

To better understand how signage supports Lean success, let’s break down each phase of the 5S system and the custom signs that bring it to life.

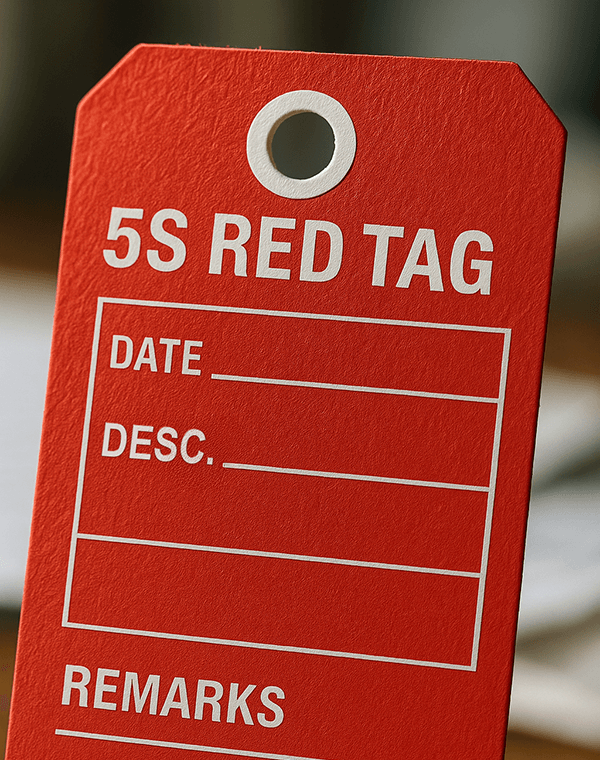

The Role of Red Tag Area Signs in Visual Waste Identification

Red tag area signs play a key role in visual waste identification during the Sort phase of 5S. This phase focuses on removing anything that doesn’t belong in the workplace, such as broken tools, outdated equipment, or excess inventory, to eliminate distractions and free up valuable space. Clearly labeled red tag signs help teams flag and separate unnecessary items, making it easier to decide what should be discarded, relocated, or repaired.

When red tag zones are consistently used and clearly marked, visual clutter is reduced, decision-making becomes faster, and waste is easier to track across shifts.

Recommended Sign Types for Sort

- Red tag labels: Use during audits to identify tools, equipment, or materials that need review or removal. Consider adding fillable fields for item status, review date, and assigned reviewer.

- Temporary holding zone signs: Mark designated areas for questionable or redundant items. A common method is labeling “Hold for Review” zones in visible, low-traffic areas to avoid mixing reviewed and active inventory.

- Inventory control labels: Help track supplies and prevent overstocking. These might include bin labels with reorder thresholds or audit dates to reduce material waste.

According to the U.S Environmental Protection Agency (EPA), companies that implement visual controls during the Sort phase often reclaim valuable space and improve workflow clarity.

With unnecessary items cleared away, the next step is organizing what remains into a clean, easy-to-navigate system.

How Floor Marking Solutions Support Lean Workflows and 5S Discipline

Floor marking solutions, such as tape, signs, and stenciled visuals, support Lean workflows by creating intuitive paths and clearly defined visual zones. These tools help employees navigate space, materials, and tools more efficiently. During the Set in Order phase, clear signage eliminates guesswork, reduces motion waste, and improves productivity.

This step ensures every tool, supply, or workstation has a designated home, and that it's clearly labeled so no one is left guessing. Custom signage brings structure to the workplace and improves communication between shifts and departments.

Recommended Sign Types for Set in Order

- Shadow board labels: Visually match each tool with a specific outline and name.

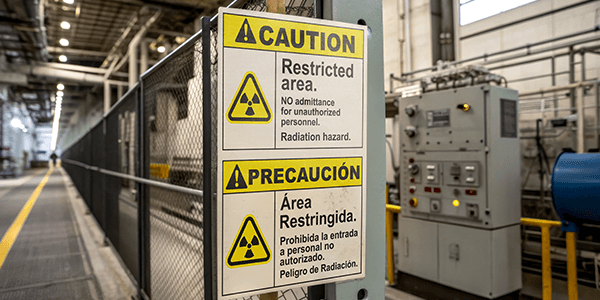

- Floor marking signs and tape: Define walkways, pallet zones, and restricted areas.

- Rack and bin labels: Identify storage areas with part numbers, item names, or color codes.

- Directional arrows and layout maps: Show the logical flow of materials and tasks.

Use color-coded floor tape to indicate traffic lanes, work zones, and storage areas (e.g., yellow for aisleways, red for defect zones). Ensure arrows align with actual process flow. For shadow boards, use real tool silhouettes and label by name, not just shape, to support quick returns and visual accountability.

Once everything is in its place, cleanliness becomes critical. That’s where Shine begins.

Shine and Visual Standards for Cleaning and Inspection Readiness

Shine focuses on maintaining a clean, safe, and inspection-ready workplace. It’s a way to uncover problems early, reduce contamination, and promote workplace pride. Signs and labels reinforce cleaning expectations, identify supplies, and standardize sanitation checklists.

Recommended Sign Types for Shine

- Cleaning station labels: Identify mop buckets, wipes, and other janitorial tools.

- Checklist boards and SOPs: Post daily, weekly, or shift-specific cleaning responsibilities.

- "Clean After Use" signs: Place at high-traffic machines or shared workbenches.

- Visual before-and-after signs: Show what “clean” looks like for critical areas.

Laminated checklists should be mounted near task zones and updated regularly. Use icons for universal understanding, especially in multilingual environments. For areas with rotating staff, before-and-after photo boards help clarify expectations and reduce variation in results.

To keep the workplace running smoothly, these practices need to be consistent, not improvised. That’s where the next phase, Standardize, takes hold.

Standardizing Labels to Build Consistency in Lean Workplaces

Standardize ensures that every team member, across every shift or location, follows the same procedures. Visual controls and consistent signage are key to locking in these behaviors and reducing variability.

Recommended Sign Types for Standardize

- Standard Work Instructions (SWIs): Visual step-by-step guides placed near machinery.

- LabelForge PRO Design Software templates: Reproducible designs for printing uniform signs and labels.

- Color-coded visual systems: Assign colors to departments, tools, or hazards.

- PPE requirement signs: Make compliance part of the routine with clear visual cues.

Establish visual standards for all labels, including font size, color use, placement, and language. Use label templates from LabelForge PRO to ensure uniformity across departments and locations. Color codes should be documented and posted where they’re easy to reference. SWIs should include updated visuals that reflect real floor layouts and task steps.

Even with strong systems in place, the hardest part is making them stick. That’s where Sustain becomes essential.

Sustain Lean Success with Ongoing Visual Reinforcement

Sustain is often the most challenging of the 5S steps because it relies on habit. This step transforms Lean from a checklist into a culture. Visual reminders, accountability boards, and daily reinforcement are what keep 5S alive over the long-term. Without signage that communicates expectations and celebrates adherence, systems tend to fall apart over time.

Recommended Sign Types for Sustain

- 5S audit boards: Display goals, progress, and metrics during team huddles.

- Leadership commitment signage: Show visible executive support for Lean.

- Reminder signs: Reinforce daily actions like returning tools or labeling new materials.

- Training visuals: Use consistent signage during onboarding and refresher sessions.

Consistent visual communication becomes second nature. It’s part of the landscape, and part of the culture. To maintain that consistency across every area, you need a flexible system for creating signs and labels on demand.

Design Durable Custom Signs with LabelForge PRO

Consistent labeling is the glue that holds Lean systems together, but managing it manually is time-consuming and often inconsistent. Sustaining a 5S system across teams, shifts, and facility zones requires a reliable, flexible way to create and update signage without disrupting operations.

LabelForge PRO, DuraLabel's free design software, simplifies the process. It includes a range of pre-built templates designed specifically for 5S labeling and workplace signage. Each one is customizable to match your facility’s layout, language, and labeling standards.

LabelForge PRO integrates seamlessly with DuraLabel Industrial Sign and Label Systems to produce durable, high-performance signage that stands up to wear, moisture, heat, and solvents.

With LabelForge PRO, you can:

- Use drag-and-drop design tools

- Choose from 5S-specific label templates

- Print signs instantly using your own equipment

- Standardize visuals across departments or sites

No more handwritten signs. No more guesswork. Just clean, consistent, compliant labeling on demand.

DuraLabel Visual Workplace Resources

Effective 5S signage is more than a checklist item. It’s the backbone of an efficient visual workplace. Custom signs that support each phase of 5S help ensure clarity, consistency, and accountability from the production floor to the stockroom.

For facilities looking to improve visual consistency across Lean operations, LabelForge PRO offers an intuitive, built-in solution. With customizable templates, industrial-strength materials, and seamless printer integration, it’s easy to build a signage system that aligns with your specific Lean goals.

Ready to get started? Download DuraLabel’s free 5S Labeling Quick Start Guide for real-world examples, material recommendations, and best practices for building signage that improves workflow, safety, and audit readiness.

Have questions? Our safety labeling experts are here to help. Call 1-888-402-8820 to connect with a visual workplace specialist.

Read Next:

5S Examples in Action: The Good, the Bad, and the Successful

How Custom Signs Support OSHA and ANSI Workplace Compliance

Related Resources

The Case for Custom Workplace Signs in Complex Environments

Why Do Custom Industrial Labels Outperform Standard Signs in Facility Environments? Custom workplace signs ...

Read

How to Make Custom OSHA Safety Signs That Meet Compliance and Last

How Do CustomSafety Signs Help Prevent Accidents and Downtime? Custom OSHA safety signs help prevent ...

Read

How OSHA and Multilingual Signage Promote Safer Workplaces

Why is Multilingual Signage Important? Multilingual safety signage helps prevent workplace accidents and ...

Read.png)