How to Make Custom OSHA Safety Signs That Meet Compliance and Last

How Do Custom Safety Signs Help Prevent Accidents and Downtime?

Custom OSHA safety signs help prevent accidents and downtime by giving workers hazard warnings that match the real risks in your facility. When signs follow OSHA labeling standards and are placed where decisions happen, they reduce confusion and speed up safe responses. The result is fewer injuries, less equipment damage, and fewer stoppages.

A generic sign won’t stop a machine from crushing someone’s hand or warn about a chemical spill waiting to happen. Custom safety signs do more because they are built around your actual workflow, equipment, and exposure points. Instead of vague messaging, they deliver specific direction workers can act on fast.

To get those benefits, facilities need to know how to create compliant custom signs, avoid common design and placement errors, and choose durable materials that hold up in industrial conditions.

The sections below break down how custom safety signs improve compliance, how to create them correctly, and what mistakes to avoid.

-

Why Custom Safety Signs Matter

-

How to Make Your Own Safety Signs for Industrial Compliance

-

Common Mistakes to Avoid When Creating Safety Signs

-

Resources and Next Steps

Why Custom OSHA Safety Signs Matter

Generic signs often fail to capture the specific risks and operational nuances in different workplaces. Custom safety signs give facilities the ability to:

- Identify unique hazards and specialized processes

- Align with NFPA, ANSI, and OSHA compliance standards

- Improve clarity, reduce confusion, and boost productivity

- Strengthen safety culture and reinforce internal policies

A well-executed custom signage strategy can significantly reduce workplace incidents, build employee confidence, and contribute to long-term operational success.

The Cost of Using Generic Signs

Generic signs may seem cost-effective at first, but they often lead to hidden expenses. Vague or broadly worded signage can overlook localized hazards, leading to more accidents and unexpected downtime. Facilities also face the risk of regulatory fines if signage fails to meet OSHA or ANSI requirements.

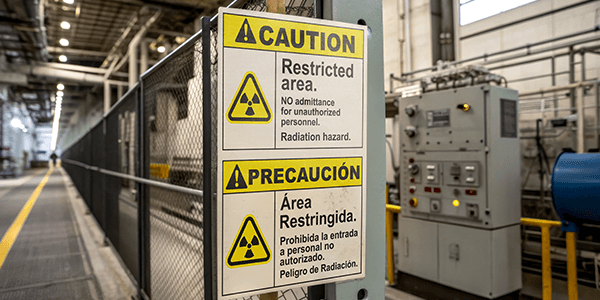

When workers encounter poorly matched or unclear signs, their trust in workplace safety measures can erode, impacting morale and productivity. For example, a manufacturing plant using a generic "Caution: Hot Surface" sign near specialized welding equipment might overlook critical hazards about high-voltage exposure or automatic machinery start-up. A custom sign that warns of both heat and unexpected motion helps prevent serious injuries and avoids costly compliance failures.

How to Make Your Own OSHA Safety Signs for Industrial Compliance

Creating effective custom safety signs begins with a clear understanding of your facility’s hazards and communication needs. Follow these steps to ensure your signs support compliance and keep workers safe.

- Identify hazards and information needs: Walk through areas with moving equipment, electrical panels, hazardous chemicals, and restricted zones. Pinpoint what workers need to know to stay safe and compliant.

- Check relevant standards: Reference OSHA regulations, ANSI Z535 standards, and NFPA codes to ensure your signage includes the correct signal words, colors, and symbols.

- Select appropriate colors and symbols: Use standardized visual cues (such as red for danger or yellow for caution) to make signs immediately recognizable.

- Write clear, concise text: Use short, direct language that can be quickly understood. Avoid jargon or unnecessary complexity.

- Design for visibility: Choose proper font sizes, layouts, and color contrast, so signs are legible from an appropriate distance under normal lighting.

Facilities that produce their own safety signage gain greater flexibility, making it easier to adapt as hazards change or processes evolve.

Common Mistakes to Avoid When Creating Safety Signs

Even with the best intentions, facilities can make costly errors when creating their own safety signs. Avoid these common pitfalls:

- Using overly complex language: Technical jargon or lengthy text reduces readability and increases the risk of misinterpretation.

- Choosing poor contrast or small font sizes: Low-contrast designs or undersized text can be difficult to read, especially in fast-moving or emergency situations.

- Ignoring environmental conditions: Failure to account for moisture, UV exposure, heat, or chemicals can cause signs to peel, fade, or fail prematurely.

- Improper Sign Placement: Even the best-designed sign is ineffective if it’s placed where workers can’t easily see it when needed.

Avoiding these mistakes helps ensure your signage remains clear, compliant, and effective under real-world conditions.

Tools You Need to Create Safety Signs for Manufacturing or Maintenance

Creating professional-grade safety signage requires more than a desktop printer and laminated paper. Industrial environments demand durable, high-clarity visuals produced with purpose-built tools.

- LabelForge PRO Design Software makes it easy to build compliant layouts by integrating standardized safety symbols, barcodes, and custom messaging.

- DuraLabel Toro Max Industrial Sign and Label System supports rugged label stock like heavy-duty vinyl and polyester, delivering crisp, smudge-resistant prints that stand up to demanding conditions.

- DuraLabel Label Stock includes material options for reflective visibility, chemical resistance, and high-heat environments—ensuring your signs stay intact and readable over time.

Selecting the right combination of software, hardware, and materials empowers your team to produce custom safety signage quickly, efficiently, and to a professional standard.

Choosing the Right Materials for Long-Term Performance

The effectiveness and longevity of custom safety signs depend heavily on material selection. Facilities must consider:

- Vinyl: Flexible and durable, ideal for general indoor and outdoor applications.

- Polyester: Highly resistant to chemicals and heat, making it suitable for harsh industrial environments.

- Reflective materials: Improve visibility in low-light areas and enhance safety during power outages or night shifts.

- Photoluminescent materials: Glows in the dark to guide workers during emergencies when lighting fails.

For example, in a food processing facility with frequent washdowns using harsh chemicals, standard vinyl signs may degrade quickly. By switching to chemical-resistant polyester signs with extra-strong adhesives, the facility maintains visibility of hygiene protocols and hazard warnings—reducing replacements, improving compliance, and avoiding downtime.

Designing Durable Signs for Industrial Environments That Last Under Pressure

Industrial environments often expose signage to extreme temperatures, moisture, chemicals, and physical abrasion. To maintain effectiveness, safety signs must be built to withstand these harsh conditions.

Choose materials that resist fading, tearing, and chemical exposure. Use strong adhesives to ensure signs stay securely in place on rough or variable surfaces. Protective laminates or coatings provide added resistance to UV rays, abrasion, and washdowns.

Designing for durability extends the life of your signage, reduces the need for frequent replacements, and helps ensure critical safety messages remain visible—supporting both compliance and workplace safety over time.

DuraLabel Custom OSHA Safety Signage Solutions

Choosing the right signage starts with understanding your facility’s specific risks and operational demands. Whether in manufacturing, utilities, or healthcare, custom safety signs deliver the clarity, durability, and compliance support needed to protect your team and maintain efficiency.

DuraLabel’s solutions are engineered for challenging environments, with materials built to last both indoors and outdoors. Paired with LabelForge PRO Design Software, DuraLabel Industrial Sign and Label Systems allow you to create compliant signs with customized text, graphics, and barcodes that meet exact regulatory and operational requirements.

By choosing DuraLabel, you gain the tools to reduce downtime, elevate safety culture, and achieve long-term success. Not sure which signs your facility needs? Download DuraLabel’s free Facility Signage Handbook or connect with a representative at 1-888-789-7964 for expert support.

Read Next:

DuraLabel’s Tough-Tested Process: Raising the Bar for Label Durability

DIY Labels or Premium Label Supply? Choosing the Right Safety Signs

Related Resources

How to Audit OSHA-Compliant Signs Before the New Year

How Does an End-of-Year Signage Audit Improve Workplace Safety? An end of year signage audit improves ...

Read

The Case for Custom Workplace Signs in Complex Environments

Why Do Custom Industrial Labels Outperform Standard Signs in Facility Environments? Custom workplace signs ...

Read

Everything You Need to Know To Be OSHA Signs and Labels Compliant

How Does OSHA Signage Compliance Support Workplace Safety? Occupational Health and Safety Administration ...

Read.png)