Food Facility Safety Practices That Shape Safer Worksites

How Does Food Safety Culture Protect Consumers?

A strong food safety culture, backed by regulations and reinforced through inspections, helps keep food free of contamination and protects consumers from preventable illness. In the United States, foodborne diseases affect nearly one in six people each year, according to the Centers for Disease Control and Prevention (CDC). Maintaining this culture is a core part of food facility safety and ongoing food safety compliance.

At the core of every safe facility is a food safety culture. These shared values and habits prevent risks long before inspections occur. September’s National Food Safety Education Month provides an opportunity for facilities to evaluate their practices and strengthen defenses against risks. Food safety depends on a layered approach built on training, durable labeling, and accountability, all of which support food facility safety.

This month also offers a chance to enhance visual communication. The free OSHA Safety Signage Quick Start Guide provides practical strategies for aligning with OSHA standards and helps facilities translate regulations into daily practices—reducing errors and reinforcing safe behavior that supports food safety compliance.

Food Safety Culture in Action

Food safety culture is the foundation of every processing plant, distribution center, and food service environment. It reflects a collective commitment to protecting consumers by embedding safe practices into daily operations. Leadership sets the tone, but every employee must participate for the culture to be effective.

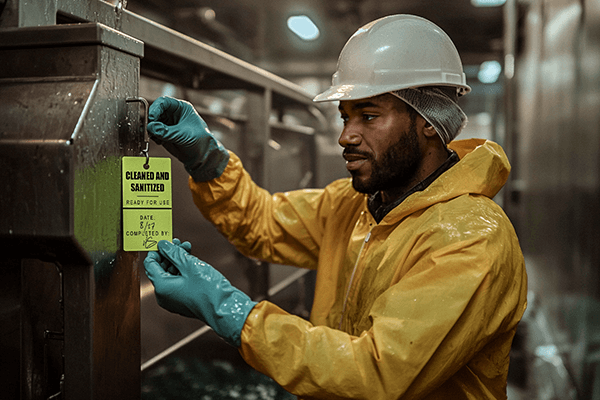

Facilities that invest in consistent training see stronger results. For example, a sanitation team trained to apply “Cleaned and Sanitized” tags after equipment washdowns reinforces accountability and builds trust with inspectors. Likewise, production staff who can recognize allergen warnings and cross-contact risks are better prepared to prevent contamination.

Visual cues are essential for reinforcing this culture. Durable safety labels, allergen notices, and hygiene reminders provide constant reinforcement that words alone cannot achieve and support overall food facility safety.

An industrial sign and label printer, such as the DuraLabel® Toro® Max Industrial Sign and Label System, enables facilities to create these reminders on demand. From allergen alerts to sanitation schedules, in-house printing gives teams the flexibility to keep messages clear, visible, and compliant.

When a facility builds food safety culture into its identity, it strengthens daily operations. Employees understand their responsibilities, supervisors can rely on consistent practices, and customers gain confidence knowing the products they consume are handled with care.

Food Safety Regulations That Shape the Industry

Even the strongest food safety culture depends on clear rules. Regulations establish the framework that ensures every facility meets consistent standards. Key governing bodies include:

- FDA (Food and Drug Administration): Oversees food safety through the Food Safety Modernization Act (FSMA), which emphasizes prevention.

- USDA (U.S. Department of Agriculture): Regulates facilities involved in meat, poultry, and egg production.

- OSHA (Occupational Safety and Health Administration): Enforces hazard communication standards for chemicals in food processing, including labeling requirements.

- GHS (Globally Harmonized System): Standardizes chemical hazard communication worldwide to ensure universal recognition of risks.

Regulatory requirements often overlap. A food processor may need GHS-compliant chemical labels for cleaning supplies, OSHA-approved safety signage for machinery, and USDA protocols for allergen separation. Durable food safety labels help bridge these requirements by staying legible during washdowns, chemical exposure, and temperature fluctuations as part of food safety compliance.

Compliance signage must also meet visibility standards. Inspectors routinely check chemical storage areas, equipment with pinch points, and refrigeration units for clear hazard communication. High-contrast colors, standardized pictograms, and strong adhesives reduce the risk of citations and strengthen audit readiness.

Food Safety Inspections and Audit Readiness

Inspections are one of the most visible demonstrations of food safety. Federal, state, and third-party inspectors assess whether facilities meet standards, maintain records, and enforce hygiene practices. Audit readiness is less about one-time preparation and more about daily habits that make inspections seamless.

Inspectors typically focus on three key areas:

- Labeling and Documentation: Expiration dates, batch numbers, allergen labels, and chemical storage signs must be accurate, visible, and intact.

- Sanitation Protocols: Teams should consistently demonstrate cleaning procedures and prevention of cross-contact.

- Visual Communication: Safety signs, hazard labels, and instructions must be placed correctly and remain in good condition.

Label degradation is a common pitfall. Faded or peeling labels on chemical containers or processing equipment create compliance gaps and can trigger citations. Facilities that print on durable food safety labels, such as chemical-resistant vinyl or metal-detectable materials, reduce these risks and demonstrate to inspectors that safety is a priority.

For example, an inspector entering a dairy facility may check that sanitizers display GHS pictograms, confirm expiration dates on perishable ingredients, and verify that allergen-containing products are clearly segregated. If labels are unreadable or missing, the facility risks fines and reputational damage.

One of the most impactful improvements a facility can make is through labeling. A strong food safety label communicates hazards, instructions, and traceability information that protect consumers and support food safety compliance.

Essential Elements of a Food Safety Label

A label is only effective if it communicates the right information. In food environments, labels must give workers and inspectors details that are clear, accurate, and durable. Requirements vary by application, but most food safety labels should include the following:

- Product Identification: Clear names for ingredients, chemicals, or finished goods help staff avoid confusion and prevent misuse.

- Hazard Information: OSHA food safety labeling and GHS chemical labels should display signal words, hazard pictograms, and handling precautions.

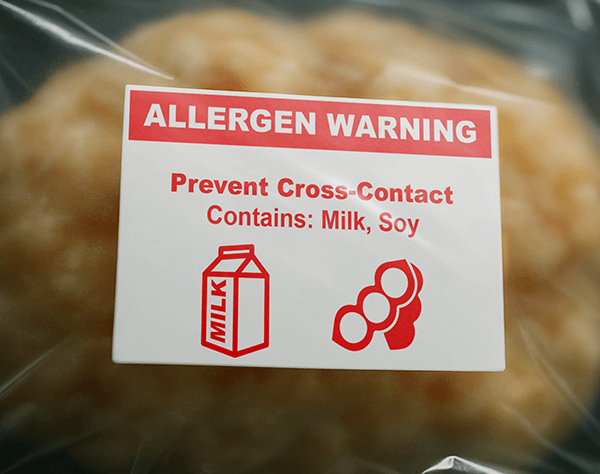

- Allergen Warnings: Labels must call out common allergens such as peanuts, milk, or soy when products are stored or prepared in shared spaces.

- Date and Batch Codes: Expiration dates, lot numbers, or production codes support traceability and reduce recall risks.

- Instructions for Use: Labels may also include sanitation directions, storage temperatures, or other critical handling requirements.

Durable food safety labels that provide this information keep teams aligned, reinforce compliance signage across facilities, and create a reliable paper trail for audit readiness—essential components of strong food facility safety.

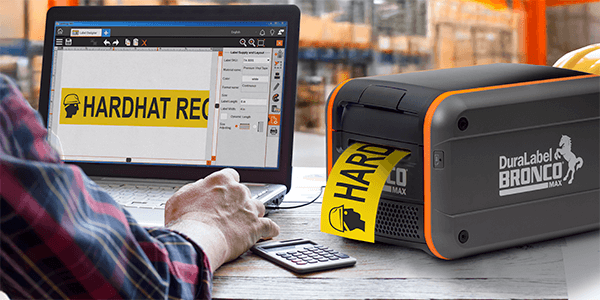

Creating Labels with DuraLabel LabelForge® PRO Design Software

Designing compliant food safety labels can be time-consuming without the right tools. DuraLabel LabelForge PRO Design Software simplifies the process with built-in templates for OSHA food safety labeling, GHS chemical labels, and allergen warnings. It also includes a library of standardized symbols, barcodes, and pictograms so teams can create professional-grade labels quickly and accurately.

When paired with a DuraLabel printer, LabelForge PRO enables facilities to produce durable food safety labels that remain legible during washdowns, cold storage, and daily handling. This combination saves time, reduces labeling errors, and keeps food safety compliance on track across the facility.

When labels deliver the right information, they form the backbone of a safer facility. The next step is putting those labels into action through daily food safety practices.

Key Food Safety Practices for Daily Operations

Food safety culture and regulatory compliance come to life through daily practices. Facilities that adopt clear, repeatable routines set themselves up for long-term success.

Some of the most effective food safety practices include:

- Conduct Routine Training and Refreshers: September is an ideal time to review hygiene, allergen handling, and equipment sanitation.

- Maintain Consistent Labeling Systems: Durable labels for chemicals, allergen zones, and equipment reduce confusion and support compliance.

- Prevent Cross-Contamination: Color-coded floor tape and bilingual signage help diverse teams follow protocols.

- Specialty Labels for Contamination Prevention: Metal-detectable labels add a layer of protection by being visible to scanning equipment.

Consider allergen management as an example. A bakery producing both nut-containing and nut-free products must label every container, utensil, and storage area with allergen warnings.

High-visibility, chemical-resistant labels that withstand frequent cleaning reduce risk and improve audit readiness. This simple practice helps prevent one of the most common—and most serious—causes of product recalls.

By combining these food safety practices with durable tools, facilities create an environment where compliance becomes part of daily routines rather than treated as a separate task. This strengthens both food facility safety and food safety compliance.

DuraLabel Products and Resources for Better Food Safety

National Food Safety Education Month highlights the importance of integrating culture, regulations, inspections, and best practices into a unified system of protection. Facilities that combine strong leadership with durable tools create an environment where compliance becomes second nature and risks are minimized.

Food safety requires labeling tools that withstand harsh environments and maintain clarity over time. The DuraLabel Toro Max Industrial Sign and Label System delivers that capability, enabling teams to produce compliant, food-safe labels on demand. From chemical-resistant supplies for sanitation stations to metal-detectable labels for packaging lines, Toro Max provides reliable performance in critical areas.

For additional support, download the free OSHA Safety Signage Quick Start Guide for practical strategies on compliance and workplace safety.

Still have questions about how labeling supports inspections or compliance? Call 1-888-786-9223 to connect with a DuraLabel expert.

Read Next:

OSHA Signs Regulations and Compliance: Everything You Need to Know

Why Tough Mechanical Environments Require Durable Labels

Related Resources

Why Every Workplace Safety Plan Must Address Electrical Hazards

What Threatens Workplace Safety in Electrical Jobs? Electrocution, arc flash, contact with energized ...

Read

How Custom Vinyl Labels Help Facilities Boost Safety and Compliance

Why Are Premium Custom Vinyl Labels Important forWorkplace Safety? Premium custom vinyl labels are gaining ...

Read

Invest in the Bronco Max Printer for Safer Facilities

Can Facility Maintenance Teams Afford to Skip Labeling? Facility maintenance touches every corner of a ...

Read.png)