Modern ERP System Adoption and the Shift Away from Legacy Platforms

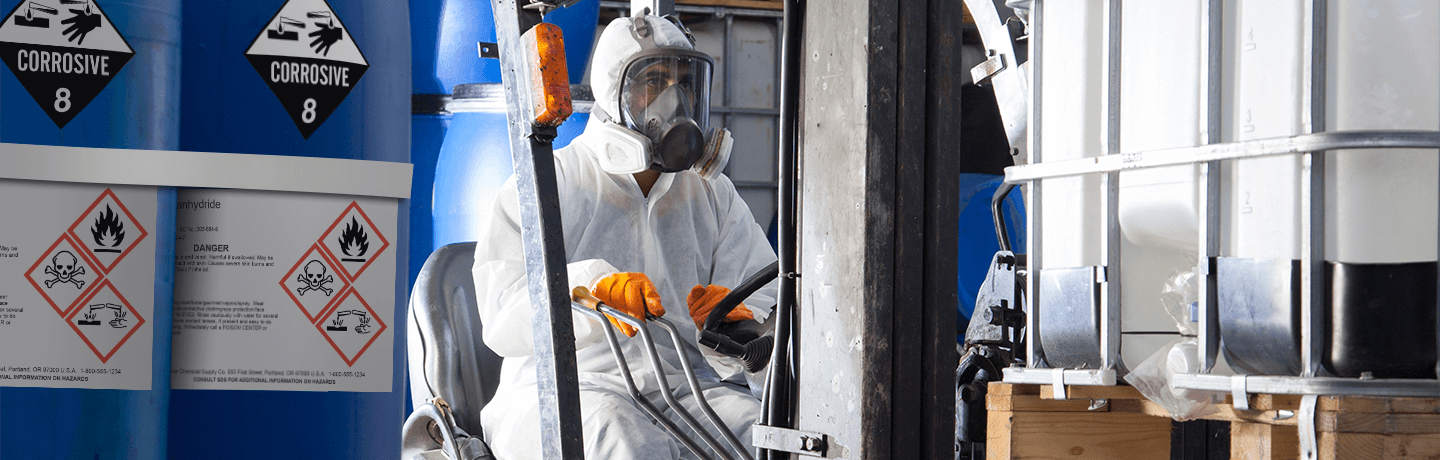

Modern ERP system adoption in a warehouse as a worker scans a flammable storage barcode label, improving inventory tracking, compliance labeling, and safer hazardous material management.

What's Driving Modern ERP Adoption in Manufacturing and Warehousing?

Manufacturing and warehousing teams are accelerating Enterprise Resource Planning (ERP) system adoption because legacy software no longer meets the speed, accuracy, or integration demands of modern operations. Organizations need real-time visibility, consistent data flow, and scalable systems that support inventory control and supply chain coordination. As a result, ERP modernization has become a practical requirement for staying competitive.

The sections below break down why legacy ERPs are failing, how cloud vs. on-prem decisions shape adoption, and what modernization costs and integrations look like in industrial environments:

- Why legacy ERP systems are being replaced now

- How cloud ERP vs on premise decisions influence adoption

- What ERP implementation costs look like in warehouses

- Why SAP S/4HANA timelines are pushing migration

- How ERP integration improves supply chain performance

- The role of physical labeling in ERP-connected workflows

Across the United States, operations leaders report that outdated systems cannot reliably connect with current warehouse tools or support continuous data movement. This disconnect creates delays, manual workarounds, and inaccurate reporting that undermine productivity. Research from ArcherPoint confirms that replacing outdated legacy systems is the number one reason companies switch ERPs, reinforcing how widespread these limitations have become.

Manufacturing is especially affected. National ERP benchmark data shows that manufacturers account for nearly half of all new ERP implementations, highlighting the sector’s push for better operational visibility and more predictable system performance. Faster order cycles, increased production demands, and tighter customer expectations have made ERP modernization a practical requirement rather than a long-term goal.

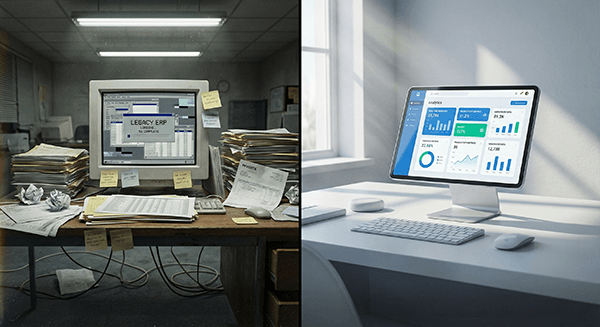

The Rising Need to Replace Legacy ERP Systems

Side-by-side comparison of legacy ERP vs modern ERP software dashboards, showing the shift from paper-heavy manual processes to streamlined digital reporting and real-time business analytics.

Organizations are moving toward legacy ERP replacement because older systems limit productivity, accuracy, and compliance. These older systems lack the flexibility to support new business models such as rapid fulfillment, multichannel distribution, and just-in-time inventory.

Legacy ERP systems often store data in isolated modules or require manual spreadsheets to bridge information gaps between departments. This creates delays in stock updates and increases the risk of miscounted inventory, misplaced materials, or missed reorders. Many older systems also lack the ability to integrate with new automation tools, modern barcode formats, or cloud-based supply chain applications.

Maintenance burdens add another layer of pressure. Support for outdated systems becomes more expensive over time, especially when hardware ages or custom code must be patched. Cybersecurity concerns further motivate replacement, as unsupported platforms leave organizations vulnerable to breaches or audit failures. Recent industry data shows why many teams now view modernization as the safer financial choice:

- $56 million a year to maintain legacy systems, on average, for large enterprises, according to a 2025 Pegasystems study conducted with Savanta

- $370 million a year in total losses tied to legacy tech and technical debt

- $4.88 million per breach in 2024, according to IBM’s annual Cost of a Data Breach study, underscoring the stakes of running unsupported platforms without current security patches.

Together, those pressures explain why upgrading to a modern ERP is increasingly less costly, and less risky, than continuing to maintain outdated systems.

How Are Cloud ERP and On-Site ERP Influencing Adoption Decisions?

Cloud-based ERP has reshaped how organizations evaluate their next system. Many companies are choosing cloud platforms to reduce infrastructure costs, speed up deployment, and improve accessibility across distributed warehouse networks. These systems update automatically, scale quickly, and reduce the need for internal server maintenance.

Smart warehouse cloud computing concept with a digital cloud overlay and security icons above racked inventory and forklifts, highlighting connected ERP systems, data protection, and real-time logistics visibility.

Market research shows a clear shift toward cloud-based systems across industrial sectors. An analysis published by IT Jungle in late 2024 reported that nearly 65% of new ERP deployments were cloud-based, signaling a strong move away from traditional in-house setups. Organizations are making the switch for several reasons, including:

- Faster scalability compared to in-house systems

- Lower long-term maintenance and infrastructure costs

- Reduced reliance on internal IT resources

- Easier integration with mobile devices and remote workflows

- Automatic updates that keep systems current without disruptive downtime

Despite this trend, onsite ERP systems remain critical for operations that rely heavily on machinery, robotics, or automated storage systems that require local stability. These environments sometimes need on-site systems to prevent latency issues or service interruptions. As a result, many companies are implementing hybrid ERP models that blend cloud flexibility with the reliability of on-site deployments.

Cloud ERP vs. On-Site ERP in Industrial Operations

| Factor | Cloud ERP | On-Site ERP |

|---|---|---|

| Deployment Speed | Faster implementation | Longer infrastructure setup |

| Infrastructure Costs | Lower upfront hardware costs | Higher hardware and server investment |

| Maintenance | Vendor-managed updates | Internal IT required |

| Scalability | Easily expandable across locations | Expansion may require additional hardware |

| Automation Integration | Strong for distributed systems | Stable for robotics-heavy environments |

| Latency Sensitivity | May face network dependency | Local control reduces latency risk |

Understanding ERP Implementation Costs in Industrial Environments

ERP implementation cost remains one of the most researched topics among organizations preparing for modernization. Organizations research ERP implementation costs heavily because accurate budgeting and realistic timelines are essential for avoiding disruptions during modernization.

Projects that involve significant data migration, multiple warehouse connections, or extensive customization typically require higher investment. Companies with multiple warehouse locations or advanced automation also face higher initial costs because of data migration, interface development, and user training. IBM’s Cost of a Data Breach study showed that many ERP projects exceed their early estimates, often due to unplanned integration work or insufficient resource allocation during the planning phase.

Despite the investment, the long-term value remains strong. Organizations that complete ERP upgrades often report improved productivity, fewer manual steps, and stronger inventory accuracy. Over time, these gains lead to reduced waste, better utilization of warehouse space, and more predictable order fulfillment. Many manufacturers also connect ERP improvements directly to faster cycle times and improved customer performance metrics.

The Shift Toward Systems, Applications, and Products in Data Processing

Many companies are preparing for Systems, Applications, and Products in Data Processing (SAP) S/4HANA migration as support for older SAP versions will expire soon. This shift is prompting organizations to evaluate migration options and align their ERP strategies with long-term technology roadmaps.

Industry timelines influencing migration decisions include:

- December 31, 2027: Mainstream support ends for SAP Business Suite 7, including ECC.

- December 31, 2030: Extended maintenance remains available through this date, offered at a higher support cost for organizations that postpone migration.

- December 31, 2025: ECC systems running Enhancement Packages 0 through 5 lose mainstream support on this earlier cutoff.

The transition offers an opportunity to replace outdated workflows and reduce customizations that slowed earlier systems. Companies are using the S/4HANA move to standardize data structures, enhance reporting accuracy, and eliminate workarounds that accumulated over years of system use.

Modern S/4HANA architecture also offers performance benefits. Its in-memory design supports faster reporting, real-time forecasting, and more resilient inventory tracking. For organizations managing high SKU volumes or variable customer demand, these improvements help streamline planning and strengthen overall responsiveness.

How Does ERP Integration Improve Supply Chain Optimization in Warehouses?

Warehouse ERP integration improves operations by connecting digital planning with physical workflow. When inventory movements, barcode scans, purchase orders, and shipping tasks feed directly into the ERP system, organizations gain real-time visibility that supports better decision-making and reduces the risk of errors.

Warehouse inventory management with a gloved worker scanning a barcode label on pallet racking, supporting real-time ERP tracking, accurate stock control, and safer material handling operations.

Integrated systems eliminate the need for disconnected spreadsheets or duplicate data entry. This supports more accurate inventory counts, tighter tracking of materials, and easier coordination between receiving, stocking, production, and shipping teams. Warehouses that operate multiple sites benefit from consistent part numbering, standardized labeling, and unified reporting across locations.

Many organizations also connect their ERP system to supply chain optimization software. These tools use ERP data to streamline planning and eliminate workflow gaps. Common improvements include:

- Automated replenishment that reduces the risk of stockouts

- Stronger forecasting based on real-time demand patterns

- Faster response to supplier delays or production interruptions

- Fewer inventory shortages across distributed warehouse sites

- More predictable warehouse flow supported by synchronized data

Together, these capabilities give warehouse teams a clearer operational picture and the agility needed to adjust quickly when conditions change. This level of visibility strengthens every stage of the supply chain, from daily material handling to long-term planning and resource allocation.

DuraLabel® Tools for Better ERP Outcomes

Modern ERP system adoption gives warehouse teams the visibility and accuracy needed to keep inventory moving without interruptions. When labeling, scanning, and workflow data feed into a single platform, organizations can reduce errors, improve coordination, and maintain consistent performance as operations scale.

DuraLabel supports these efforts with durable, industrial-grade labeling solutions built for ERP-connected environments. Our materials are designed to remain legible in high-traffic, high-wear conditions, helping warehouses maintain data accuracy and clear communication.

DuraLabel also offers LabelForge® PRO Design Software, a free sign and label design software that includes thousands of templates, automated supply detection, and built-in compliance modules. LabelForge PRO helps teams create accurate, standardized labels that stay aligned with ERP records and warehouse workflows.

For teams working to align physical labeling with digital systems, DuraLabel’s free Warehouse Labeling Quick Start Guide provides practical steps for improving scan accuracy, choosing the right materials, and standardizing labels across the facility.

Have questions? Call 1-888-789-7964 to connect with a DuraLabel safety specialist for support with labeling, integration, and workflow planning.

Read Next:

How Papé Streamlined Fleet Tracking with DuraLabel

5 Reasons to Upgrade Your Industrial Printer Before the New Year

Related Resources

HMIS Labeling and How the HMIS Labeling System Works

How Does the HMIS Labeling System Work? The Hazardous Materials Identification System (HMIS)uses color bars ...

Read

Why a GHS Labeling System Matters for Hazard Communication

What Is GHS Labeling? GHS labeling is a standardized method for communicating chemical hazards in the ...

Read

What GHS Chemical Labels Mean for Ammonia System Safety

What Are Common Ammonia Hazards? Ammonia is a highly hazardous chemical commonly used in refrigeration and ...

Read.png)