When Facilities Should Upgrade an Industrial Label Printer

When Should You Upgrade Your Industrial Label Printer?

Facilities should upgrade an industrial label printer when the current system can’t keep pace with compliance and production demands. Common signs include inconsistent print quality, slow output, frequent downtime, limited material options, or difficulty producing OSHA- and ANSI-aligned labels and signage consistently across the facility with an equipment labeling system.

The end of the year is often a practical window to make that change. Many facilities use this time to evaluate equipment, prepare for audits, and align budgets with upcoming operational goals. Replacing outdated systems before inspection and production needs spike helps teams enter the new year with a safer, more efficient labeling process already in place—especially when an industrial label printer supports multiple departments.

For teams weighing their options, a side-by-side comparison can make the decision easier. To support that process, DuraLabel® offers an industrial sign and label system comparison flyer that highlights the differences between its Bronco® Max, Toro® Max, and Kodiak® Max printers—making it simple to choose the best fit for any workplace.

An industrial sign and label system plays a bigger role than many facilities realize. From compliance to day-to-day efficiency, its impact reaches across departments and industries. Here are five clear reasons to make the switch before the new year.

1. Maximize Year-End Budgets and Planning for an Industrial Label Printer

As fiscal years close, many organizations look for strategic ways to allocate remaining funds. Investing in a new industrial labeling system before year-end puts those budgets to work on equipment that delivers long-term value.

Rather than spending on temporary solutions or generic supplies, a new in-house system positions teams to start the year with stronger compliance tools already in place. For some facilities, this comes down to the “use-it-or-lose-it” nature of capital budgets.

If funds go unused, they may not roll over to the next year—leaving safety upgrades delayed or forgotten. By allocating budget toward a printer upgrade now, facilities set themselves up for stronger compliance, greater efficiency, and a smoother start to the new fiscal year.

Audits also become easier when upgrades are planned before January. A company preparing for a first-quarter inspection benefits from purchasing new equipment before the year ends. That way, the inspection reflects updated compliance measures rather than outdated equipment.

Even the best financial planning falls short if compliance risks remain—making updated labeling capability the next key reason to upgrade.

2. Strengthen Compliance Before New Regulations Take Effect

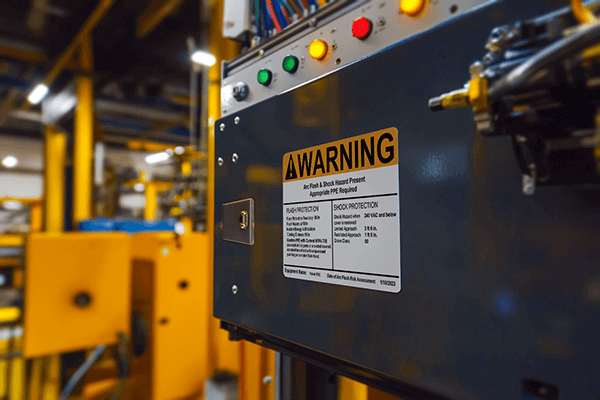

Labeling requirements evolve over time. NFPA, ANSI, and OSHA standards continue to update rules for electrical labeling, pipe marking, and hazard communication. Printers that cannot produce compliant labels place facilities at risk of citations. Upgrading now ensures teams are prepared for inspections and ready to meet the latest requirements.

For example, NFPA 70E mandates clear arc flash labeling that identifies incident energy, PPE requirements, and approach boundaries. A safety label printer equipped with up-to-date templates and durable supplies provides the accuracy and consistency needed to pass audits and protect workers, especially when paired with an equipment labeling system.

To stay compliant across industries, industrial label printers are designed to meet standards such as:

- OSHA Hazard Communication Standard (HCS): Chemical safety labeling

- ANSI Z535: Standardized colors and signal words

- NFPA 70E: Arc flash hazard labeling

- GHS: Consistent chemical hazard communication across industries

Some labeling violations—including those involving electrical panels or chemical containers—can result in fines over $10,000 under OSHA’s penalty structure. An up-to-date printer capable of producing compliant labels helps avoid these costly setbacks while supporting a safer workplace.

A reliable safety label printer also ensures facilities maintain audit-ready communication year-round, reducing the risk of sudden compliance gaps.

Compliance is essential, but efficiency matters too. That’s where in-house printing capabilities become a game-changer.

3. Improve Efficiency With an In-House Equipment Labeling System

Relying on outside suppliers for labels can cause delays, especially when hazards change or equipment layouts shift. By upgrading to an in-house label printing system, teams gain the ability to design and print labels on demand using an industrial label printer. This reduces downtime, speeds up hazard response, and improves overall workflow. Consider a warehouse that needs to update rack labels after a seasonal inventory change.

With an upgraded industrial sign and label system, staff can produce durable barcodes, aisle markers, and safety reminders in minutes instead of waiting days for outsourced orders. The result is fewer operational interruptions and smoother transitions between shifts or processes.

Efficiency gains also extend across departments:

- Safety Teams: Print hazard and PPE labels for equipment and work areas.

- Maintenance Staff: Produce equipment IDs and lockout/tagout markers.

- Warehouse Managers: Generate barcodes, rack labels, and floor markers.

When every department relies on the same workplace labeling system, facilities benefit from consistent design, reduced confusion, and a unified visual language. In-house printing also cuts waste since teams only print what they need, when they need it.

A unified labeling system also simplifies training, as staff across departments follow the same process for creating and applying labels.

While efficiency reduces delays, advanced software ensures every label created meets compliance and safety standards.

4. Access Advanced Software for an Equipment Labeling System

Hardware is only one side of the upgrade equation. Software drives accuracy, efficiency, and compliance.

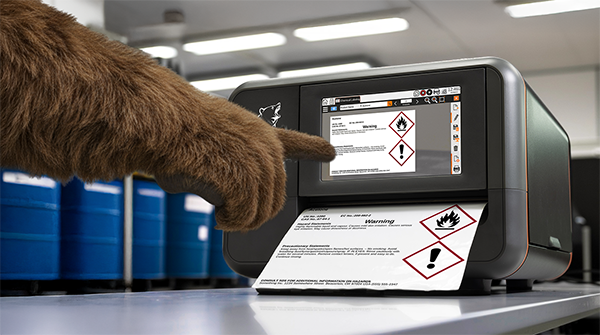

DuraLabel LabelForge® PRO Design Software, included free with all DuraLabel printers, provides built-in templates for OSHA, ANSI, NFPA, and GHS standards. It includes more than 3,000 ready-to-use designs and a symbol library of over 1,800 safety icons.

Workers, such as compliance officers, can use LabelForge PRO to generate GHS-compliant chemical labels or NFPA diamonds in just a few clicks. Arc flash modules simplify what would otherwise be a time-consuming task, auto-generating labels based on analysis data.

This eliminates guesswork and reduces errors, making compliance easier to maintain. Generic design tools often lack these features and can introduce inconsistencies across facilities.

LabelForge PRO keeps every label aligned with regulatory standards. With the ability to merge spreadsheets, generate sequenced barcodes, and import facility-specific images, the software offers both flexibility and control.

Teams can standardize formats across multiple sites or departments, building consistency while reducing variability. For many facilities, this kind of compliance labeling software transforms labeling into a faster, more reliable process.

With software handling compliance and consistency, the final piece is durability—making sure the labels themselves last in demanding environments.

5. Rely on Durable Technology Built for Harsh Environments

Labels are only effective if they remain intact and legible. Modern thermal transfer printers paired with tough-tested supplies create labels that withstand heat, chemicals, abrasion, and moisture.

Older printers may not support the high-performance materials needed in these environments. For example, outdoor electrical boxes require labels that resist UV rays and temperature swings.

A durable label printer with the right supply stock ensures critical warnings remain visible for years. This reduces replacement costs and keeps workers safe.

Durability is especially important in industries with demanding operating conditions, such as:

- Construction: Dust and abrasion can quickly wear down surfaces.

- Food Processing: Labels must withstand harsh washdowns and chemicals.

- Utilities and Energy: High temperatures and exposure demand specialized supplies.

- Manufacturing: Moving parts and solvents put constant stress on labels.

Modern sign and label printers support specialized supplies for each of these conditions, giving facilities confidence that their safety communication will last in the toughest environments.

Choosing a durable sign and label system also lowers long-term replacement costs, making it both a safety and financial advantage.

Building Long-Term ROI With an Equipment Labeling System

Beyond compliance and efficiency, upgrading your industrial sign and label system generates a long-term return on investment (ROI). Fewer label replacements reduce supply costs, and durable materials cut down on waste.

Improved clarity also helps prevent costly accidents. Facilities save time by reducing delays associated with outsourced printing or noncompliant labels.

Viewed through the lens of ROI, an industrial sign and label system upgrade is not just an operational improvement—it is a financial strategy. The combination of cost savings, risk reduction, and stronger safety outcomes delivers measurable value well beyond the initial purchase.

Step Into the New Year with an DuraLabel Industrial Label Printer

Upgrading before the new year is a step toward lasting efficiency and safety. With modern technology and in-house printing capabilities, facilities can start the year prepared for audits, inspections, and everyday operational demands with a consistent equipment labeling system.

DuraLabel Industrial Sign and Label Systems are designed to meet those needs. Every system combines thermal transfer printers, tough-tested supplies, and intuitive software to deliver professional-quality labels and signs on demand. From hazard communication to equipment labeling, these industrial sign and label systems provide the flexibility and durability required across industries. Investing in a modern industrial sign and label system ensures your facility enters the new year prepared for both compliance and efficiency.

To help choose the right system, download the DuraLabel Industrial Sign and Label System Comparison Flyer, which provides a clear breakdown of features and use cases for each model.

If you’d like expert assistance tailoring a labeling solution to your facility, call 1-888-695-5670 to connect with a DuraLabel representative today.

Read Next:

Why Upgrade to the DuraLabel Toro Max Industrial Sign and Label System

A Comprehensive Guide to Choosing the Right Industrial Label Printer

Related Resources

Why Engineers Rely on LabelForge PRO for OSHA Electrical Safety

What Is LabelForge PRO and What Is It Used For? DuraLabel LabelForge® PRO Design Software is an industrial ...

Read

Hazard Communication Solutions for a Safer Workplace

A faded label. A missing hazard symbol. An outdated SDS. These small details can trigger big problems in ...

Read

Learn How to Create Custom Safety Signs In-House with DuraLabel

Why Should Facilities Create Custom Safety Signs In-House? Creating clear, compliant signage is a constant ...

Read.png)