Industry

Construction

Challenge

Papé needed a durable, efficient labeling solution for barcoding its rental fleet. Previous machines frequently failed, and labels could not withstand outdoor conditions, leading to tracking and inventory challenges.

Results

With DuraLabel Barcode Labels, the company now barcodes its rental fleet across five locations using durable, weather-resistant labels. This has simplified tracking, boosted productivity, and strengthened safety compliance.

Key Product

“[DuraLabel Barcode Labels] made our lives easier.”

Michele Davidson

This Papé facility provides heavy equipment rentals across Seattle and Western Washington, supporting contractors and operators with reliable machinery for construction and industrial projects. Michele Davidson, Rental Administrator, oversees rental processes and fleet operations, where clear asset identification and efficient tracking are essential.

The Challenge

Before implementing DuraLabel Barcode Labels, Papé struggled with inadequate labeling solutions for its rental fleet. The team’s previous machines frequently broke down, and the labels could not withstand the outdoor conditions—quickly fading, peeling, or falling off.

These shortcomings created inefficiencies in tracking and managing inventory across multiple rental sites. With equipment spread throughout Western Washington, the lack of durable, standardized labeling made it difficult for staff to maintain consistency and reliability in fleet identification. The company searched for a dependable solution for more than six months, evaluating several options—including online label makers and Brother products—but none provided the quality or support required.

The Solution

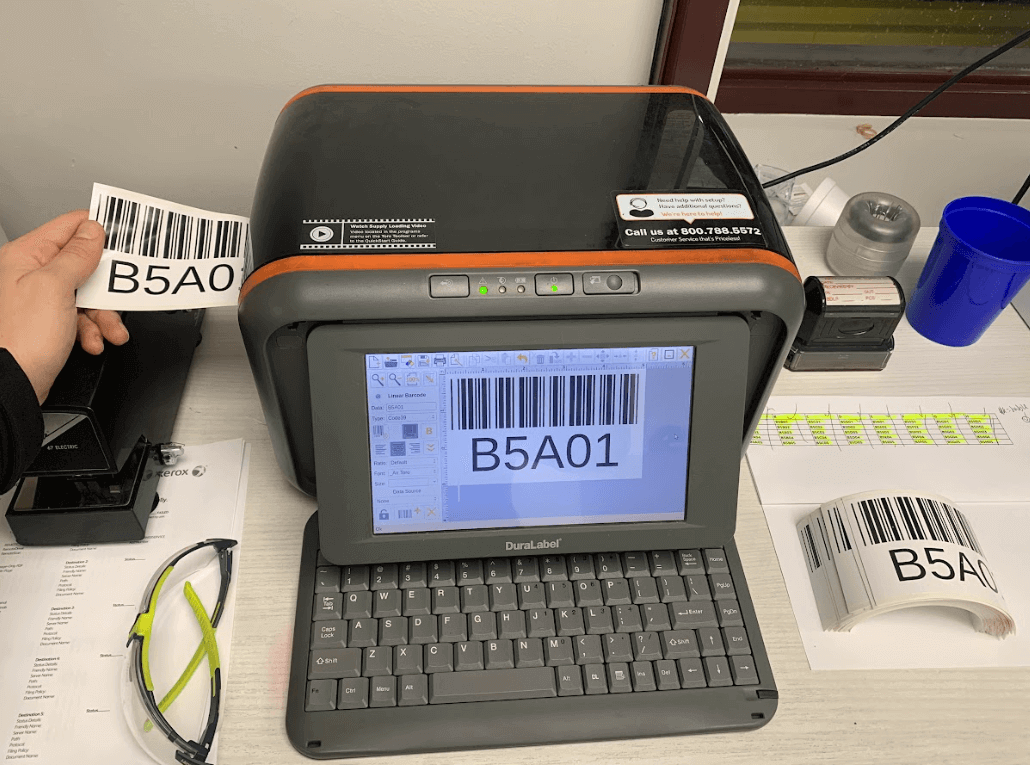

Papé turned to DuraLabel Barcode Labels to standardize barcoding across its rental fleet. With DuraLabel’s durable materials and reliable print systems, the company gained a solution that withstands outdoor conditions while supporting multiple users across five sites. The new system enabled teams to:

-

Print long-lasting, weather-resistant barcode labels for heavy equipment in outdoor environments.

- Standardize asset identification across five rental locations.

- Simplify inventory tracking and fleet management with easy-to-scan barcodes.

- Eliminate reliance on unreliable machines that previously wasted time and resources.

- Adopt quickly with no unplanned adjustments, allowing multiple team members to begin using the system right away.

“[Other] labels didn’t withstand the outside elements.” – Michele Davidson

The Results

After just one month of use, DuraLabel Barcode Labels have improved efficiency and reliability for Papé. The company now maintains accurate, consistent fleet labeling across multiple sites, cutting down time spent on manual tracking and re-labeling.

The durability of DuraLabel Barcode Labels has eliminated previous frustrations with fading or failing labels, giving teams confidence in their ability to manage assets effectively. Along with supporting safety compliance, the solution has delivered measurable productivity gains—simplifying workflows and making daily operations easier for staff across the region.

.png)