Why Custom Industrial Labels Matter for Mechanical Job Sites

Mechanical job sites are fast-paced environments where precision and organization are critical. Mislabeling can lead to safety hazards, compliance violations, and financial losses. A recent study found that 76% of manufacturers mislabel more than 10% of their goods, causing over $1.3 million in annual losses worldwide. Custom industrial labels help prevent these costly mistakes by ensuring clear, consistent identification across job sites.

Clear, job-specific labels help workers quickly identify equipment, pipes, and safety hazards, reducing errors and streamlining workflows. Whether it's contractor labeling solutions for tools or safety labeling for hazard areas, the right system keeps operations organized, efficient, and safe.

The Role of Custom Labels in Mechanical Job Sites

Custom labels are more than just stickers—they are an essential part of any contractor’s toolkit for maintaining organization and ensuring workers have easy access to critical information. These labels help teams quickly find what they need and follow proper procedures, whether for equipment identification or hazard communication.

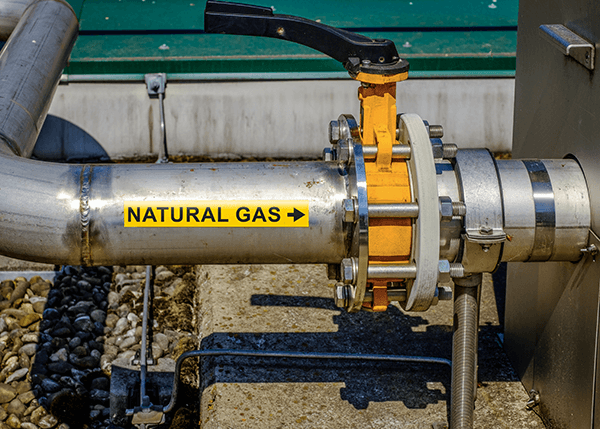

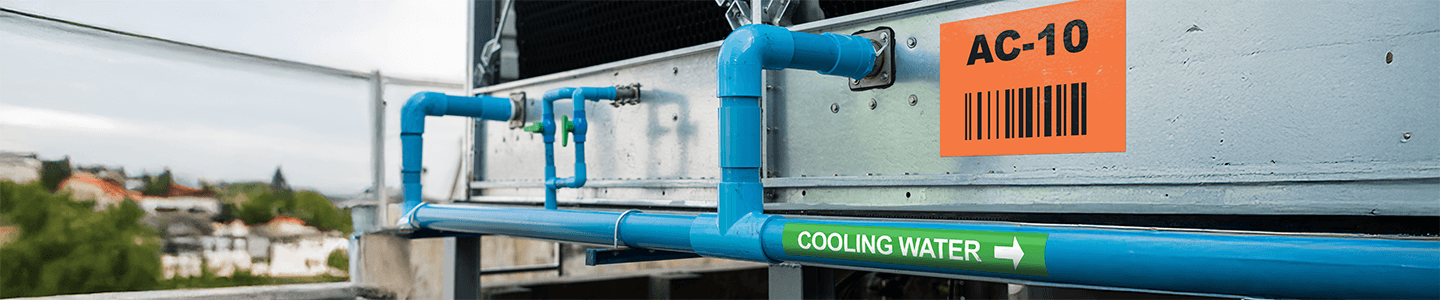

For example, contractor labeling solutions prevent misplaced tools and misused assets, while pipe identification labels clearly mark contents and flow direction to avoid costly installation errors. Standardized labeling also improves communication between teams, ensuring consistency across a project.

Without durable, readable labels, workers may resort to verbal instructions or handwritten notes, increasing the risk of miscommunication. Additionally, many of these signs and labels remain on-site for future residents, facility managers, and maintenance teams.

Accurate labeling reduces complaints, legal risks, and ensures long-term clarity for those who rely on this information. A structured labeling system improves workflow efficiency, accuracy, and overall safety.

Prioritizing Customer Safety and Confidence

Beyond improving efficiency, contractors must also consider customer safety and approval. Clearly labeled equipment, pipes, and hazard areas reassure clients that the site meets best practices and regulations. A well-organized, properly marked environment demonstrates professionalism and reduces liability concerns.

For example, an HVAC contractor must label refrigerant lines to prevent future maintenance errors, while clearly marked safety zones help customers and employees navigate the site safely.

Standardized labeling not only protects workers but also builds customer trust, reinforcing a commitment to safety, compliance, and quality work.

Reducing Errors with Clear Identification

Mistakes on mechanical job sites can lead to rework, delays, and safety risks. Custom industrial labels address these issues by providing clear, durable identification for components.

Key ways custom industrial labels help reduce errors include:

- Equipment identification labels: Mark tools, machinery, and assets to prevent loss and assist with maintenance.

- Pipe identification labels: Indicate contents, flow direction, and hazards to improve compliance and avoid errors.

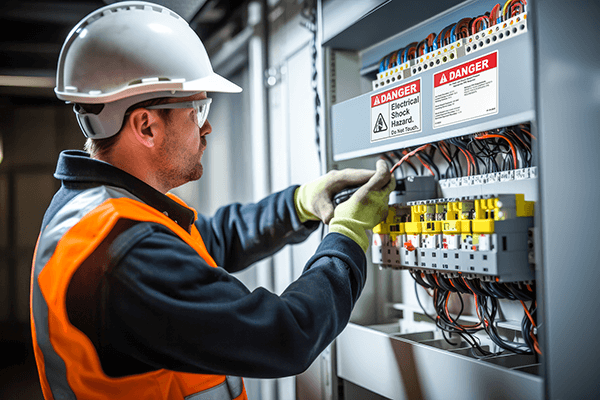

- Hazard and safety warning labels: Alert workers of dangers, required personal protective equipment (PPE), and restricted areas to prevent accidents.

- Material and inventory labeling: Organize materials and track inventory with clear labels to prevent misplacement.

Custom labels for mechanical job sites reduce miscommunication and human error, creating a safer and more efficient work environment.

Improving Efficiency with Custom Labeling Solutions

Efficiency is critical in mechanical work, where delays can be costly. A clear labeling system helps workers quickly find tools, identify materials, and follow procedures.

For example, a contractor working on a large-scale HVAC system can use pipe identification labels to mark different refrigerant lines, avoiding mix-ups. Similarly, safety labels help workers quickly identify hazard areas, enhancing site navigation and awareness.

Choosing and Implementing the Right Labels for Mechanical Job Sites

Not all labels are built to handle the harsh conditions of mechanical job sites. These environments expose labels to extreme temperatures, moisture, chemicals, and heavy wear. Durable custom industrial labels, like DuraLabel’s UL 969-Compliant Poly Labels, ensure long-lasting visibility and reliability.

Labels must meet specific requirements to perform effectively on mechanical job sites and remain long after the work is complete:

- Equipment identification labels should resist fading, peeling, and abrasion.

- Pipe identification labels need strong adhesion and chemical resistance to withstand oils, solvents, and temperature fluctuations.

- Safety labels should feature bold, easy-to-read text and graphics so workers can quickly recognize hazards.

- Asset and inventory labels with barcodes, QR codes, and company branding improve tracking and compliance.

But even the most durable labels are only effective if they are applied consistently. A standardized labeling system ensures every worker can quickly understand and act on the information provided.

Standardizing Labels for Clarity

Standardized colors, symbols, and fonts ensure that workers of all experience levels can quickly and accurately interpret information. This is especially important for safety labeling and pipe marking, where OSHA and ANSI standards help prevent workplace accidents.

Proper Label Placement

Once a facility’s labeling system is standardized, proper placement ensures labels stay visible and effective. A well-placed label is easy to spot and minimizes the chance of confusion. Labels should be positioned at eye level whenever possible and applied to clean, dry surfaces to prevent peeling. Safety signs should be visible from all entry points, while equipment labels should be placed near operating controls or access panels for quick reference.

Meeting Compliance Standards with Custom Industrial Labels

Beyond organization, standardization also plays a key role in regulatory compliance. Industry standards, such as OSHA’s Hazard Communication Standard, dictate how certain labels must be designed and displayed to meet safety requirements. Investing in an on-demand labeling solution, like a thermal transfer printer, enables teams to quickly produce durable labels as needed.

Regulatory compliance is a major concern on mechanical job sites, where failing to meet industry standards can result in fines, project delays, or safety violations. Custom industrial labels help contractors stay compliant by ensuring proper identification of equipment, hazardous materials, and required safety measures.

For example, OSHA and ANSI standards require clear hazard communication, including safety labeling for confined spaces, high-voltage areas, and required PPE. Similarly, pipe marking must follow ANSI/ASME A13.1 color codes to indicate contents and flow direction. Custom labels that meet these standards help prevent compliance violations and improve workplace safety.

Failing to comply with these regulations can lead to serious consequences. OSHA citations for improper labeling can result in fines exceeding $16,000 per violation, and repeated offenses can bring even higher penalties. Beyond financial costs, unclear or missing labels contribute to workplace accidents, equipment damage, and miscommunication between teams. In high-risk environments, such as power plants or mechanical assembly lines, even a minor labeling mistake can lead to costly downtime or life-threatening hazards. By standardizing labels and using durable materials, contractors can create a safer, more organized job site where every worker has the information they need at a glance.

DuraLabel Custom Labeling Solutions for Mechanical Job Sites

Effective labeling on mechanical job sites requires durable materials and a reliable labeling system that withstands harsh conditions. DuraLabel provides custom industrial labels designed for extreme environments, ensuring long-lasting identification for equipment, pipes, and safety hazards.

With the portable DuraLabel Toro Max Industrial Sign and Label Print System and tough-tested supplies, contractors can quickly create equipment identification labels, pipe marking, and safety labels on demand at mechanical job sites—reducing downtime and improving accuracy.

DuraLabel’s custom sign and label service offers professional printing for large-scale projects, delivering ready-to-use labels tailored to specific job site conditions. Whether you need contractor labeling solutions for tools or custom labels for mechanical job sites to improve workflow, DuraLabel has the right products to meet your needs.

Learn how better labeling can reduce errors and streamline operations with DuraLabel’s free Facility Signage Handbook. Call us today at 1-888-973-2045 to connect with a safety professional who can help you choose the best labeling solutions for your job site.

Read Next:

Keep Job Sites Safe: How Custom Labels Change the Game for Contractors

Choosing the Right Industrial Label Printer for Your Business Needs

Related Resources

Keep Job Sites Safe: How Custom Labels Change the Game for Contractors

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical ...

Read

Why Tough Mechanical Environments Require Durable Labels

Unlike normal adhesive stickers, industrial labels must resist harsh conditions that quickly degrade ...

Read

8 Essential HVAC Installation Tips to Prevent Costly Mistakes

HVAC Installation Done Right: 8 Essential Tips to Prevent Costly Mistakes A poorly installed heating, ...

Read.png)