Lean Manufacturing Process

What is the Lean Manufacturing Process?

The Lean Manufacturing process is a structured lean 5S process for eliminating waste and optimizing workflow efficiency. It uses Lean workflow steps like Kanban, 5S, and continuous improvement (Kaizen) to drive measurable improvements in quality and productivity.

Widely referred to as "lean," the lean process has principles that focus on improving products and services based on what customers want and value. By reducing waste and improving customer satisfaction, the Lean production process saves companies money and improves overall profitability for long-term success.

How to Start the Lean Process

Becoming a lean facility is not something that can be done overnight, even when implementing a kaikaku radical change. Lean is a significant undertaking that requires comprehensive planning and total commitment from the workforce. Fortunately, several lean manufacturing methods are easy to start using. Those include:

- Using a simple manufacturing system

- Using a continuous improvement program

- Using metrics to measure the effectiveness of improvements.

Simple Manufacturing

Simple manufacturing is a streamlined process that uses a pull system to produce products based on customer demand. While there are several ways to implement a pull system, Kanban is one of the most effective and proven tools for doing this.

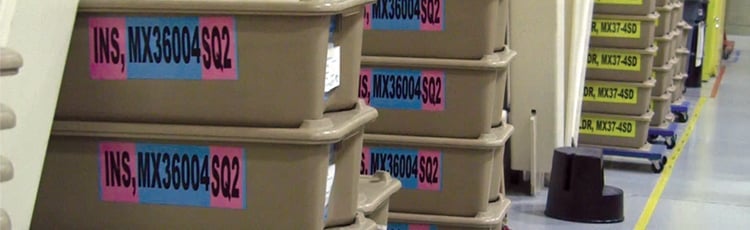

Kanban is a system that uses visual signals (cards) to control the flow of materials within a supply chain. Kanban works because:

- Every item, bin, box, or pallet has a Kanban card attached to it. The Kanban card lists the items and quantity that should be ordered so that the production floor can order the correct parts.

- The production floor may only order parts listed on the attached Kanban card and only when their current supply runs out or reaches a specified level. Workers remove the card and send it to the purchasing department.

- The purchasing department only sends supplies that are listed on the Kanban card. They cannot send supplies unless they receive a Kanban card.

By controlling the supply chain, businesses will:

- Reduce waste caused by producing too much or too little

- Reduce inventory and increase workspace

- Increase productivity by limiting the work-in-progress (WIP)

- Improve the overall workflow.

Continuously Improve

Continuous improvement is the foundation of the lean process. More commonly referred to as Kaizen, continuous improvement supports the lean process by creating a culture where every worker-from the CEO to the production floor assistant-looks for ways to improve the company. Generally, individual improvements are relatively small; however, over time the changes result in major improvements.

A culture of continuous improvement can be cultivated in the workplace by:

Welcoming all suggestions: Act on all good ideas-no matter how small. This will help Kaizen gain momentum and ensure it is practiced.

Communicating the positive effects: It is important to share how improvements have helped the company. This will demonstrate the worth of the program and encourage employees to submit new ideas.

Showing trust: Companies can also encourage participation by allowing employees to implement their ideas. This shows employees they are trusted and helps Kaizen become part of the workplace culture.

Visual communication is a key element that can help businesses establish a culture of continuous improvement. Strategically placed labels and signs can communicate changes in workflow, ensuring that workers can seamlessly move from one task to another, even when procedures change. Once established, continuous improvement will provide the foundation needed to support the lean process.

Measure Improvements

For the lean process to be successful, the efficiency of business practices needs to be continuously monitored. Statistical Process Control (SPC) and tracking Overall Equipment Effectiveness (OEE) are two methods that help business measure improvements and identify areas that need attention.

SPC is a quality control tool that can be used to monitor and control processes through metrics. SPC can be implemented using a control chart. Businesses can use a control chart to record information and see when processes stop working. Once a problem is found, workers can solve the problem as well as any new issues that occur.

OEE is a combination of equipment availability, performance, and production quality. OEE should be measured before and after improvements are implemented. Regularly measuring the OEE will help businesses track the effectiveness of improvements, spot problems when they occur, and identify areas that need immediate improvement.

SPC and OEE are valuable tools that can help businesses implement the lean process. These tools will make it easier to develop solutions that are targeted to the areas that need them the most.

Lean Manufacturing Solutions

There are many tools that can help businesses with the lean process. In addition to Kaizen and Kanban, companies can use 5S to support their implementation of simple manufacturing and continuous improvement.

5S is a systematic tool that creates functional order within a company. 5S accomplishes this with the five S's:

- Sort: Unneeded items are removed from the workplace

- Set in Order: Each work area is organized for convenience and efficiency

- Shine: Employees clean their workspace each day to spot potential issues and keep the area organized

- Standardize: Improvements are documented, so they can be applied throughout the workplace

- Sustain: Each step in 5S is repeated daily.

Following these steps will make it easier to implement Kanban and Kaizen by creating a well-ordered environment where employees can move from one workstation to another without having to spend time learning the new layout.

Take Action Today

Need a handy tool for lean process solutions? Download our free Kaizen and PDCA Best Practice Guide or call us today at 1-888-788-9936. One of our experts will help you integrate Lean Manufacturing process into your workflow using proven Lean strategies and DuraLabel industrial labeling tools.

Related Resources

Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter? Lean manufacturing principlesare core ...

Read

Toyota Production System

What Is the Toyota Production System and Why Does It Matter? TheToyota Production System(TPS) is a ...

Read

How to Improve Quality Control in Manufacturing with Lean and 5S

What Is Quality Control in Manufacturing and Why Does It Matter? In manufacturing, quality control is a ...

Read.png)