Pipe Makers & Pipe Labels | Piple Marking Labels

Workplaces are safer than ever, but challenges remain: In 2014, nearly three million nonfatal workplace injuries were reported by private industry employers, and more than 4,600 workers were killed on the job.

Yet proper safety signage can have an enormous impact on curbing these troubling statistics. Effective visual communication can raise awareness of workplace hazards to reduce risks and promote safety in a simple, affordable, and efficient manner.

OSHA 1910.145 is the agency's specification for signs and tags that identify hazards which could harm people or cause property damage. The standard specifies design requirements and when to use safety signs; these elements are developed further in the ANSI Z535 standard, which uses alert symbols and pictograms to communicate hazards.

This article explains why you should use safety signs throughout your facility, how they can help, and how to use safety signs most effectively.

Benefits of Safety Signs

Adequate safety signage has numerous benefits for facilities large and small.

- Reduce workplace accidents: With clear, specific safety signs, workers can recognize when to take certain precautions, stay out of restricted areas, wear different types of PPE, and more. Safety signs also encourage workers to watch out for hazards and minimize risks.

- Increase efficiency: Strong communication lets employees know where to go in a facility (or where not to go) and helps them understand more clearly the hazards that may be present in a quick, clear manner.

- Promote a culture of safety: Adequate signs and labels demonstrate to employees (and OSHA) your commitment to a safe work environment that recognizes hazards and accounts for risks.

When Should You Use Safety Signs?

In short: Use safety signs and labels whenever hazards are present-or whenever they may be present-in your facility. But which signs should you use to denote hazards?

OSHA and ANSI have established three primary severity classifications for safety signs. The following types of signs correspond to the severity of hazards present (or potentially present) and can be used to guide your facility's decision-making process:

- Danger: Danger signs alert workers to the most serious hazards, where special precautions are required. The "DANGER" signal word is printed in white letters on a red background and is preceded by the safety alert symbol; it indicates that death or serious injury will occur if the immediate hazard is not avoided.

- Warning: One hazard level below danger signs, these describe a hazard that could result in death or serious injury if not avoided. The "WARNING" signal word is printed in black on an orange background and is preceded by the safety alert symbol.

- Caution: These signs indicate that potential hazards may exist; if not avoided, they may result in minor or moderate injuries. These typically caution against potential injuries from unsafe practices. On caution signs, the "CAUTION" signal word is printed in black on a yellow background header and is preceded by the safety alert symbol.

A secondary hazard classification exists for biological hazards.These signs signify the actual or potential presence of biohazards and assets (containers, equipment, rooms, materials, and more) where biological hazards like potentially infectious material may pose a risk to workers.

Read more about required colors, symbols, and messages on safety signs. Duralabel has also produced an infographic that broadly outlines ANSI Z535 design standards.

Several other signs help employees stay safe without alerting them to specific hazards. They include:

- Notice: Use notice signs to provide information relevant to a building, an area, a machine, or equipment. These signs address practices and precautions unrelated to personal injuries, including procedures, instructions, maintenance information, rules, and directions.

- General safety signs: These provide notices of general facility practice, rules relating to health, first aid, medical equipment, sanitation, housekeeping, and suggested general safety measures.

- Admittance: Admittance signs don't have a defined hazard category and may use elements of other categories. They generally alert and explain the risks and consequences of entering a restricted area.

- Fire safety: Fire safety signs alert workers to the presence of emergency firefighting equipment. They should not be used for wayfinding or emergency exit applications.

Additionally, non-hazard signs communicate broad facility information, usually through simple text and clear symbols. These should never be used to describe hazards or risks, but rather to convey wayfinding directions, work procedures, general information, and more. These are not classified as safety signs but nevertheless contribute to workplace safety.

Where to Display Safety Signage?

If you're deciding where to put signs at certain points in your facility, consider asking the following questions:

- Are hazards present?

- OSHA requires safety signs at locations where a present (or potentially present) hazard threatens the safety of a worker

- Will the worker see the sign(s)?

- OSHA 1910.145(f)(4) maintains that the sign's signal word must be readable from at least five feet away

- Does the location give employees ample opportunity to avoid the hazard?

- Is there clear direction to safety and fire equipment?

- Is redirection necessary?

- Is maintenance performed in this area?

- Is it a high-traffic area?

Safety Sign Solutions

Labeling, signage, and visual communication are vital components of a safe work environment. Customized or site-specific messages can alert workers to hazards, promote safe behavior, and reduce workplace accidents.

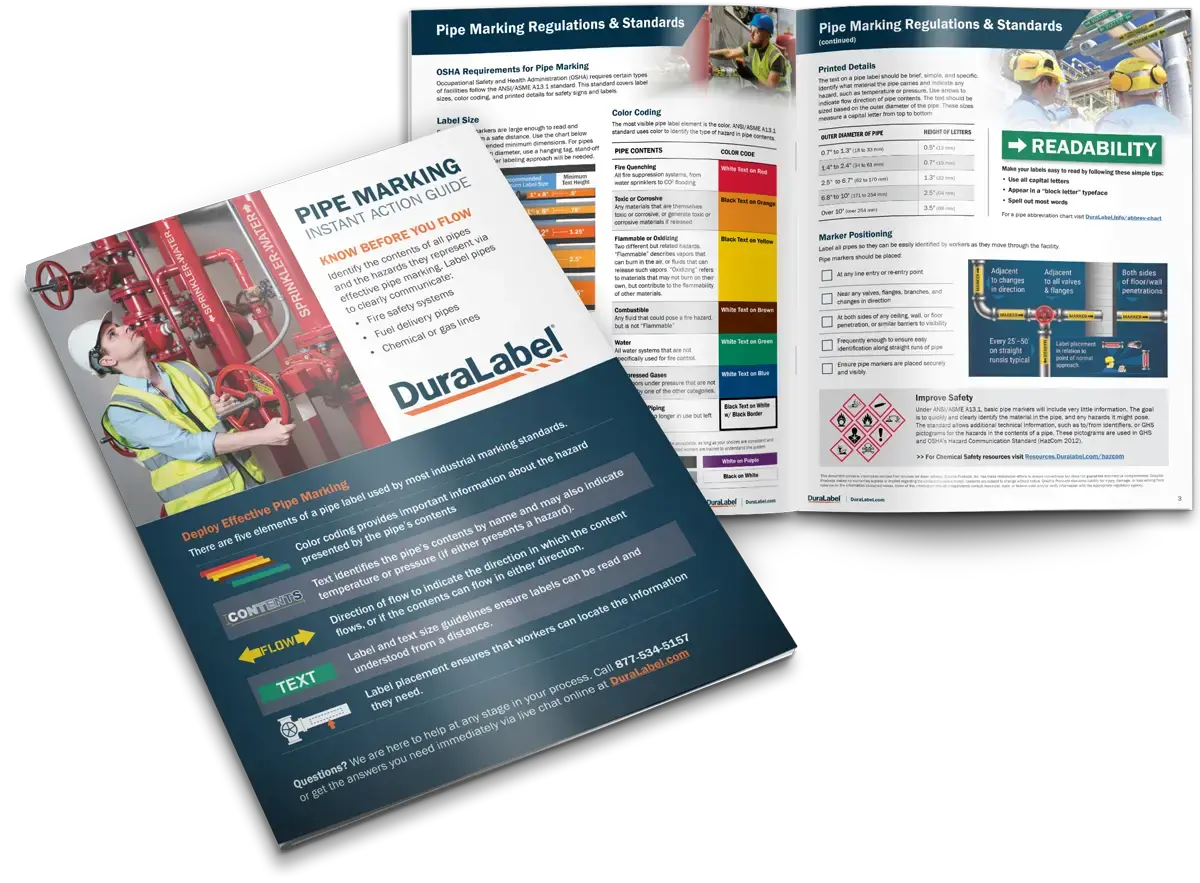

DuraLabel industrial label and sign printers by Duralabel can help you develop strong custom visual communication that keeps workers safe and invested in a culture of safety. DuraLabel printers can be used with more than 50 supplies suited to unique facility environments, including Ultra-Aggressive Vinyl for abrasive or uneven surfaces, Reflective or Phosphorescent material for low-light areas, Marine Label Stock that stands up to saltwater exposure, Oily Surface Supply for greasy environments, and Cold Storage Supply for refrigerated settings.

For more in-depth information, request your free Best Practice Guide to OSHA Safety Signs. The guide provides an overview on labeling in accordance with OSHA and ANSI standards, instructions for creating custom signs, and more.

Duralabel also carries a wide selection of premade safety signs, available in various materials and sizes.

Need help figuring out what exactly your facility needs? Duralabel offers an on-site Safety Compliance Service. A certified safety professional can review your labeling and signage efforts, offer recommendations for effective visual communication, and offer solutions for improving safety throughout your facility.

Not ready to enlist our services for safety compliance? Download our free OSHA Safety Sign Guide below to conduct your own basic facility audit.

Related Resources

.png)

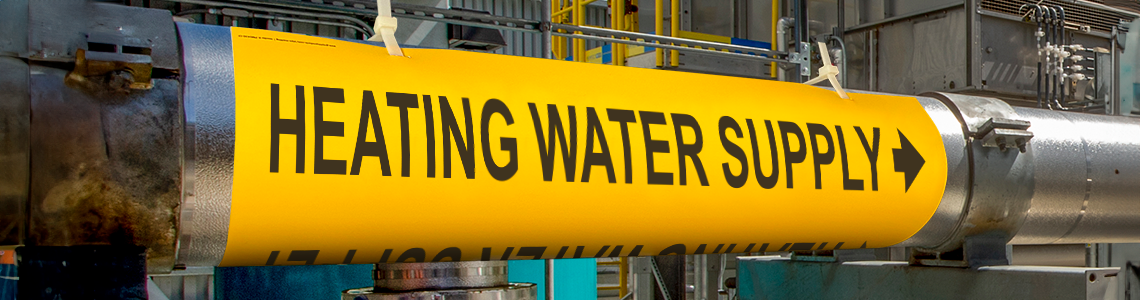

Navigating Pipeline Pathways with Directional Pipe Markers

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These ...

Read

Safety that Sticks: Using Pipe Labels for Every Size and Type of Pipe

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational ...

Read

The Benefits of Pipe Marking

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe ...

Read.png)