How Visual Tools Support OSHA Food Safety in Food Processing Plants

Why Are Electrical Safety Solutions Essential in Food Processing?

Electrical safety is a high-stakes concern in every facility because mistakes can be catastrophic. One wrong move can cause severe injury, trigger an arc flash, or shut down an entire operation.

This is especially true in food processing plants, where conveyor systems, chillers, mixers, and other high-powered machinery are essential to production.

The sections below break down why electrical risks are so serious in food processing and how visual systems help control them.

-

The biggest electrical risks in food processing plants

-

How electrical incidents cause injuries and downtime

-

Why clear visuals support training and osha food safety

-

Examples of visual tools used in food plants

-

How NFPA 70E and OSHA requirements apply

That’s why the smartest workplaces don’t just rely on training and protocols. They support them with clear, visible communication. From color-coded conduit labels to custom electrical hazard signs, visual systems help electricians and technicians work faster, more safely, and more confidently. In environments governed by the National Fire Protection Association (NFPA) 70E, OSHA standards, and time-sensitive tasks, those visuals aren’t just helpful—they are critical.

What Makes Electrical Safety So Complex?

Electrical systems are growing more sophisticated, with increased automation, tighter regulatory checks, and more distributed teams. This setup raises the stakes. Without clear documentation or labeling, even experienced electricians can lose valuable time tracing wires, identifying circuits, or determining the correct personal protective equipment (PPE).

For instance, during an unplanned outage, technicians must act fast to isolate faults. If circuits are mismarked or not labeled at all, the risks multiply. Visual breakdowns often occur when the stakes are highest: during emergency maintenance, shift turnover, or equipment failure.

This is where visual communication becomes more than a best practice. It becomes a survival tool.

In food processing, the stakes are even higher. Electrical system failures or maintenance delays can lead to more than lost production—they can cause product spoilage, contamination, and expensive cleanups.

A short lapse could mean hydraulic fluid in the bread dough or missed allergen controls in packaged snacks. Preventing these risks starts with faster, safer troubleshooting—and that depends on clear visual labeling.

Why Labeling Tools Matter in Electrical Safety

Visual tools eliminate guesswork. Whether someone routes a circuit, verifies lockout procedures, or maintains a panel, labels and signs provide instant clarity. That clarity is essential in electrical safety settings, where equipment complexity and downtime costs are high.

Consider a technician arriving for a maintenance check. If a disconnect switch lacks labeling, they might waste time tracing wires or potentially expose themselves to energized equipment. A simple voltage warning label, PPE icon, or identifier could prevent that delay or injury entirely.

Visual communication also plays a key role in:

- Preventing errors during troubleshooting or repairs

- Clarifying control panel layouts

- Reducing confusion during shift changes or emergency response

Even experienced electricians benefit from reinforcement. Nobody memorizes every conduit path or panel ID in a busy facility. Visual references keep electrical safety top of mind and make complex environments easier to navigate.

How Do Visuals Help Meet NFPA 70E Labeling Requirements?

According to the National Center for Biotechnology Information, electrical injuries result in approximately 1,000 deaths and 30,000 non-fatal shock incidents annually in the U.S. That statistic alone reinforces why NFPA 70E exists and why visual tools are a key part of many workplace safety programs.

NFPA 70E best practices include arc flash boundaries, incident energy labeling, PPE protocols, and lockout/tagout procedures. Labels and signage help facilities implement those practices visibly, making compliance easier to manage and enforce.

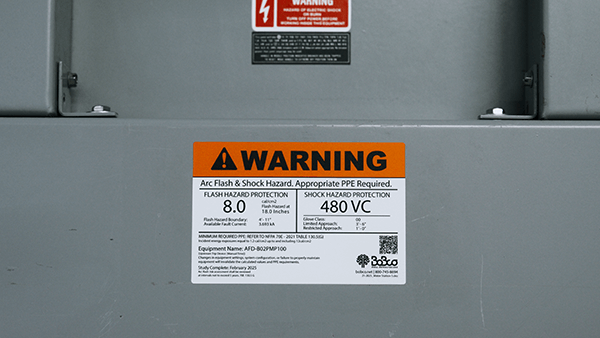

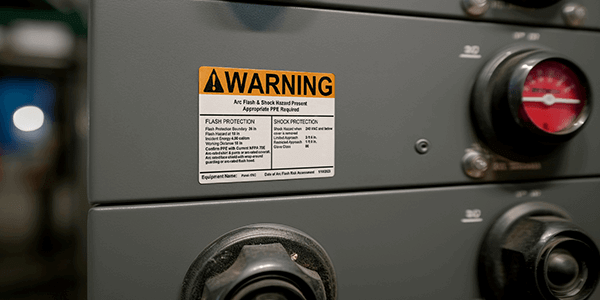

For example, arc flash labels on switchgear should display the voltage rating, calculated incident energy (in cal/cm²), PPE requirements, working distance, and shock protection boundaries. Verbal briefings can’t cover all that effectively. Visual communication does the heavy lifting, especially when multiple crews or contractors are on-site.

Arc Flash Labels That Withstand Food Processing Environments

Arc flash hazards are a concern in any facility with high-voltage equipment, but food processing environments present unique challenges. Frequent washdowns, fluctuating temperatures, and humid conditions mean labels must stay legible and securely in place despite constant exposure.

That’s why facilities rely on durable arc flash labels made from industrial-grade vinyl and printed with thermal transfer technology. These labels resist moisture, chemicals, and abrasion to remain compliant over time. For example, a food plant may apply arc flash labels to electrical panels near processing lines. Even after multiple washdowns and daily cleaning routines, those labels must continue to display critical safety details such as incident energy, voltage, and PPE requirements.

Floor Marking Tape: Reinforcing Electrical Safety on the Floor

Arc flash labels warn workers about electrical hazards, but they don’t define physical spaces. That’s where floor marking tape comes in. In busy food processing plants—with forklifts, foot traffic, and tight workspaces—floor tape helps workers instantly identify safe zones and hazard areas.

By applying high-visibility, durable floor tape, facility managers can:

- Mark arc flash boundaries around energized electrical equipment

- Create clear, color-coded paths that guide foot traffic safely

- Reinforce lockout/tagout protocols with visual cues at ground level

For instance, if an arc flash label specifies a 4-foot safety boundary, floor tape outlines that zone clearly on the plant floor, reducing the chance of accidental exposure during inspections or maintenance.

Using Software to Support Electrical Labeling Compliance

An effective electrical safety system combines durable labels, floor markings, and reliable software to keep hazards clearly identified and up to date. Tools like DuraLabel’s free LabelForge PRO help food processing facilities streamline the creation of NFPA 70E-compliant labels for panels, disconnects, and conduit systems.

Food processing facilities rely on LabelForge PRO to support their broader labeling programs by enabling teams to:

- Access templates for arc flash, voltage warnings, and lockout/tagout labeling that align with NFPA 70E requirements

- Autofill label data directly from spreadsheets or equipment lists to maintain accuracy across all safety visuals

- Customize layouts using symbols that meet National Electrical Code (NEC) and American National Standards Institute (ANSI) standards, helping ensure every label integrates seamlessly into the overall safety system

For example, when a plant updates its electrical panels after a machinery upgrade, LabelForge PRO helps generate updated labels that align with regulatory standards and maintain consistency across production areas—keeping the facility’s visual safety system current and effective.

Workplace Safety Campaigns That Reinforce Electrical Labeling

Electrical safety is a system of ongoing awareness and reinforcement. That’s why many safety managers launch annual or quarterly workplace safety campaigns—reminders that compliance is part of the culture, not just a checklist.

Visual communication supports these efforts by reinforcing PPE signage in high-voltage zones, marking approach boundaries, and replacing worn or outdated labels with current information. When treated as living tools rather than static posters, these elements help workplace safety campaigns stay visible and effective.

DuraLabel Resources for Electrical Safety Programs

A reliable electrical safety system combines smart software with durable, code-compliant labeling. DuraLabel offers the tools you need to build and maintain clear, effective safety visuals that meet regulatory compliance.

LabelForge PRO software streamlines the creation of electrical safety labels with preloaded templates and intuitive design tools, helping teams produce compliant, consistent labels for panels, disconnects, conduit, and more.

Download LabelForge PRO for free to streamline your labeling process and meet compliance standards with confidence.

For durable performance in harsh environments, DuraLabel Arc Flash Labels provide critical reinforcement. Made from industrial-grade vinyl, they resist moisture, chemicals, and abrasion, ensuring hazard warnings stay visible and secure—even in washdown zones and high-traffic areas.

Want to learn more about electrical safety labeling at your facility? Call 1-888-411-3520 to speak with an expert.

Read Next:

The Importance of Labeling for Safe, Compliant Electrical Installations

Essential Electrical Labeling for Contractors and Facility Managers

Related Resources

The Overlooked Fix That Improves Electrical Panel Safety

How Do Electrical Panel Labels Improve Safety and Compliance? Electrical panels are essential to every ...

Read

Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary? An arc flash protection boundary defines the minimum safe distance ...

Read

From Flash to Ash: Understanding Arc Flash Hazards and Prevention

What is Arc Flash? When it comes to electrical safety, arc flash is one of the most dangerous—and most ...

Read.png)

.webp)