Value Added vs. Non-Value Added Activities

What is value and how do we identify activities that add value and those that do not add value?

Value can simply be defined as something a customer is willing to pay to receive. If a customer is not willing to pay for it, then there is no value. For example, let's say your company manufactures widgets and you offer free 24-7 customer support for your widgets. To provide the best customer service you always have at least one knowledgeable technician available to answer customer questions 24 hours a day, seven days a week. On the other hand, your competitor only offers email support, with a guarantee of getting an answer within 48 hours, and they sell their widgets for 5% less than the price of your widgets. Because of their lower price you are losing several major customers to your competitor every month. If this is the complete story, what is most likely the problem?

Your customers do not place much value on having 24-7, live customer support. They prefer the lower price. That places 24-7 customer support in the category of waste.

Defining Value

Everything we do either adds value or does not add value to the product or service our company sells. Who determines whether value is being added? The customer does.

Let's take the example of a receptionist who works for a manufacturing company that makes widgets. Does this person add value to the widgets? Who are the "customers" this person is serving? Her customers are the people who need to meet with people from outside the company. That means her customers are people in the purchasing, administration, HR, and engineering departments. The receptionist is also protecting the company's propriety information by only allowing authorized people to enter the building. So the receptionist's "customers" -the people she is providing a service for- are all internal customers. If the receptionist is not providing value for those customers that exceed the cost of having a receptionist, they will either be replaced or the receptionist position eliminated.

Anything or anyone who does not add value is waste.

Keep in mind that the receptionist is also indirectly adding value to the products your company ships to your customers. By saving time for other people in your company, and protecting your company's assets, there is value added to the product you are selling.

Value Added vs. Non-Value Added - The Seven Wastes

Lean manufacturing principles divide waste into seven categories.

- Waiting (idle) times

- Excess motion (transportation)

- Handling (moving things)

- Excess or useless inventory

- Overprocessing

- Overproduction

- Defects

In addition, when talking about value added vs. non-value added activities we need to include the category of required activities on the non-value added side. Let's look at each of these, starting with required activities.

Value Added vs. Non-Value Added - Required Activities

Required activities are those which must be done, but they do not necessarily add value for either internal or external customers. The most common required activities are those required by law or government regulations. While some required activities do add value, in many cases they are activities that must be done, but they add no value. However, that does not mean they cannot be optimized, eliminating waste, to reduce the costs of the required activities.

Some people categorize business activities such as HR (hiring) and building maintenance as required business activities that do not add value. However, these activities are not non-value adding required activities. For example, finding and hiring the right people, at the time when they are needed, and doing it efficiently, adds value. An organization's human resources are its most important resources. The HR department is providing a valuable service to each of the other departments within the organization, that in turn allows them to do a better job of adding value to the products they produce.

Waiting Time

This is one of the most obvious wastes and it clearly does not add value. For example, if a machine operator is killing time waiting for the next batch of components to arrive, there is waste that can be eliminated through better scheduling. However, not all waiting time is wasted time.

Let's say that a worker's job is to unload large blocks of wood from a pallet and place them into the inlet hopper of a finishing machine. He unloads them as quickly as possible so that the forklift with the pallet can perform other tasks, and then he waits about ten minutes for the next pallet to arrive. Is this waiting time wasted time? Not necessarily. In some jobs "waiting time" can be valuable rest time that workers need if they are to continue to do their job well.

However, in the example above, there are numerous opportunities for improvements for eliminating waste. For example, why does a person need to physically move large blocks of wood. Might there be a better way of doing this using machinery?

The definition of waiting time is idle time in which someone who could be doing something is doing nothing. Eliminating or reducing this idle time is eliminating waste and improving the value added activities.

Excess Motion

The term "excess motion" refers to the movement of materials, supplies, and equipment. In the above example, why is a forklift bringing blocks of wood from one location to another location? Let's say that in this example wood is cut into blocks in a sawing operation, then moved to a warehouse for storage, and then moved on pallets to the location where a worker loads the wood blocks into the finishing machine. Excess motion can be eliminated by having the finishing machine near the sawing operation. The wood is then cut to the right size and immediately passed to the finishing machine, eliminating the need to move it in and out of a warehouse. The excess motion (transportation waste) of the wood has been eliminated.

Excess Handling

Excess handling refers to the unnecessary activities of workers and the unnecessary handling of products, machines, and equipment. In the above example, why must a worker move the blocks of wood from a pallet into the hopper of the finishing machine? What if the blocks of wood came out of the saw machine and went directly into the finishing machine? The wood blocks no longer need to be handled by an employee, eliminating that waste.

Excess Inventory

Inventory costs money for the storage space as well as taxes on the inventory. Inventory increases the risks of shrinkage, spoilage, and obsolescence. It also increases handling costs as items need to be moved in and out of inventory, and man-hours must be used to count the inventory on a regular basis. Only a minimal, absolute necessary inventory should be maintained such that it is adding value to the final product or service. Excess inventory is waste.

Let's look at our wood block example again. In a week the sawing operation can produce enough wood blocks to keep the finishing machine supplied for a month. Since the sawing operation does the cutting for a number of other products, it makes wood blocks for a week, with the blocks being stored in a warehouse until they are needed later in the month. It does the same for three other products. The result is four warehouses, each capable of holding a month's supply of the material needed to make a product.

But what if the cutting operation spends just one day on each product? Each day it makes enough for four days of operation of the finishing process for each product. The result is that each warehouse only needs to store four days worth of material instead of four weeks. The inventory storage costs along with the associated risks have just been cut by 75% as the result of eliminating excess inventory.

Overprocessing

Over-process means that more work is being put into a product or service than is needed by the final customer. If the finishing process for the wood blocks includes applying ten coats of high-quality epoxy paint with sanding and polishing between each step, but the customer only requires that the finished blocks be painted black, there is too much work going into the finishing process ? meaning the extra work (and epoxy paint) is being wasted.

Overproduction

Overproduction means making more product than what is immediately needed. If more wood blocks are being produced than are being sold, they will accumulate in a warehouse. This may make sense if most wood blocks are sold during the four weeks prior to Christmas and supply needs to be built up prior to the holiday season. In most cases, over-production results in high levels of wasteful inventory.

Defects

Defective products must be thrown out or fixed. Defective services must be done over. Doing things right the first time is essential to eliminating waste. While eliminating all defects may seem like an impossible task, there are lean methods such as Poka-Yoke, that are so effective at eliminating defects that they also eliminate the need to inspect for defects, producing even greater savings.

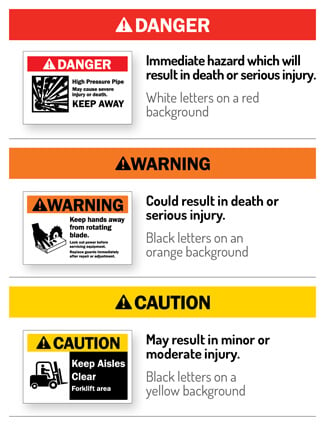

Value Added vs. Non-Value Added - The Need for Signs and Labels

The proper use of labels and signs will aid your efforts to reduce and eliminate waste. For example, they communicate needed information such as new or revised operating procedures at the place and time where the information is needed. They provide directions, guiding people safely to their destinations. And they provide critical safety information and identify the locations of safety equipment. However, signs and labels only work if they are posted, their message is clear, they remain in place, and are readable. To help achieve successful workplace practices and compliance, utilize DuraLabel industrial label printers and tough-tested supplies by Duralabel.

Related Resources

Process Cycle Efficiency (PCE)

The Process Cycle Efficiency, sometimes referred to as the "Value Added Ratio," is a measurement of the ...

Read

Value Stream Mapping in Lean Manufacturing

What is Value Stream Mapping? Value stream mapping is a lean manufacturing technique that follows the ...

Read

Lean Manufacturing in the Food Industry

Why the Food Industry is Going Lean The food industry is vast and serves hundreds of millions of people each ...

Read.png)