5 Top Solar Energy System Strategies for Safety

When it comes to new and upcoming projects in the solar industry, the heat is on. Solar installation projects are increasing year over year to meet energy targets and sustainability efforts, according to solar energy experts. With great demand comes an influx in workloads for many contractors. That is why it is paramount for workers to understand solar installation and maintenance hazards and safety.

Solar in Demand

Solar is not the latest in energy efficiency, but more businesses are grasping the concept of all-solar functionality for financial and a multitude of other reasons. There are more than 8,700 solar projects in the database, according to the Solar Energy Industries Association. These projects are mostly for large-scale infrastructure. For example, the Chattanooga Airport in Tennessee recently became the first airport in the nation to run nearly 100 percent on solar power. It is only a matter of time before other large industries follow suit.

"This project has immediate benefits to our airport and community, and we're proud to set an example in renewable energy for other airports, businesses, and our region," said Terry Hart, president and CEO of the Chattanooga Airport. "While generating a local renewable resource, we are also increasing the economic efficiency of the airport."

With an increasing number of solar projects, the demand for workers is growing. There are more than 242,000 solar workers in the United States, according to the National Solar Job Census of 2018. There are electrical safety standards by the NEC, ANSI, and ASME that are in place to help protect those who install and maintain solar energy and photovoltaic systems. Workers need to understand the hazards with which they are working, and workplaces should have a safety plan in place from the get-go.

Solar Safety

Here are a few tools and methods to think about when installing and maintaining solar energy systems:

Here are a few tools and methods to think about when installing and maintaining solar energy systems:

- Job Hazard Analysis: Focus on job tasks and identify each hazard. Consider environmental factors, the tasks, tools, and workers. Try to eliminate all hazards and communicate hazards and protocol to the workforce.

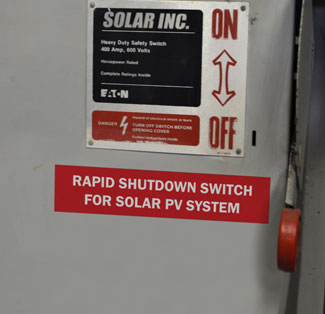

- Signs and labels: Electrical equipment needs labels, which are an essential part of communicating to the workforce. They also must follow the National Electrical Code. Make sure signs and labels, and even pipe markers, are in the right place, such as on junction boxes, conduit, switches, panel doors, meters, and disconnects. Also, make sure they have the correct information on them to properly warn workers of hazards and work boundaries using the latest labeling standards from the NEC.

- Emergency plan: Mark exit routes and maintain emergency safety equipment, such as eyewash stations and fire extinguishers. Plan for emergencies through an emergency action plan.

- Documentation: Keep a record of the JHA and review it often. Also, keep a map of the solar system and where equipment is located for easy reference and planned maintenance.

- Maintenance: Prepare a maintenance plan using the Total Productive Maintenance method. Streamline processes and tailor them with lean principles to limit downtime and to amplify efficiency.

Solar installation and maintenance plans that keep workers and businesses safe begin and end with having the right information and tools available. Any energy work has its hazards, so mitigating those hazards continually can keep the workflow running smoothly. Identify and control workplace hazards through a JHA and utilize visual communication tools for a simple and cost-effective way to manage work and keep production in order.

Improve the safety of photovoltaic systems through compliance with labeling requirements by downloading our free Solar Photovoltaic (PV) Labeling guide.

DuraLabel Solar Solutions

Solar installation projects involve various factors, including labeling to ensure compliance and safety. DuraLabel offers solutions to address these needs. The DuraLabel Toro Max Solar Panel Kit and DuraLabel Bronco Max Solar Panel Kit use materials designed to withstand environmental factors like UV radiation that ensures labels last longer.

DuraLabel’s extended-life vinyl tapes and detailed labeling guides help installers adhere to NEC requirements and maintain clarity and safety in solar installations. For advice and solutions, contact DuraLabel’s experts at 1-888-965-3359.

To help navigate the NEC's latest labeling requirements, DuraLabel developed a comprehensive Solar Labeling Guide that will help you understand the labels your installation will need.

Read Next:

Pulling Back the Curtain: A Look at DuraLabel’s Tough-Tested Process

Related Resources

The Key to Reliable Construction Projects: Safety Signage That Works

Construction signs and labels play a crucial role in protecting workers and keeping projects on schedule. ...

Read

Redefining Job Site Safety Through Better Custom Labeling

How Do Contractors Use Labels and Signs for Better Job Site Safety? The final steps of a project are just as ...

Read

How 5 Industries Rely on Custom OSHA Signs to Cut Hazards

How Can Construction Safety Signs Reduce Injury Risks in Fast-Paced Job Sites? Construction safety signs ...

Read.png)