Don’t Just Label It—Build a Pipe Marking Plan That Works

Why is Pipe Marking Critical for Safety and Compliance?

In industrial environments, whether dealing with aging ammonia systems or advanced low-emission liquefied natural gas (LNG) piping, pipe marking plays a critical role in keeping workers safe and operations compliant. Unlabeled or mislabeled pipes can lead to confusion, response delays, environmental violations, and serious injury. These incidents don’t just threaten worker safety—they can result in expensive downtime, regulatory fines, and long-term damage to your facility’s reputation. A strong pipe labeling system is essential to maintaining accountability, boosting operational efficiency, and reducing the hazards of unmarked pipes.

A properly marked pipe provides immediate clarity about what’s inside, where it’s going, and how hazardous it might be. This information is essential for everyone on-site—especially maintenance teams and emergency responders who may not be familiar with the facility’s layout. The hazards of unmarked pipes are often underestimated until an incident occurs.

Understanding the Risks: Hazards of Unmarked Pipes

Overlooking pipe identification invites serious safety risks. When a pipe is unlabeled or mislabeled, workers may misjudge its contents, leading to exposure to high pressure, extreme temperatures, or hazardous chemicals. In high-risk environments, even a moment of uncertainty can result in injury, operational disruption, or environmental harm.

Unmarked pipes expose facilities to greater regulatory scrutiny. Agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) require clear labeling for systems that transport hazardous materials. A single missing label can result in a citation, escalate liability concerns, or trigger enforcement action. Accurate pipe labeling strengthens safety, supports efficient maintenance, and keeps your facility aligned with industry regulations.

Compliance and Accountability

OSHA’s General Duty Clause requires employers to provide a workplace free of recognized hazards. That includes following established labeling standards, such as ANSI/ASME A13.1, for pipe systems that contain hazardous materials or are part of emergency response procedures. Inadequate labeling can trigger citations, especially when regulators determine the issue could result in worker harm.

The Value of Custom Pipe Labels

While off-the-shelf solutions can cover basic needs, most industrial environments benefit from custom pipe labels tailored to their specific systems. Custom labels provide additional clarity by including facility-specific terminology, contents, flow direction, and relevant hazard warnings. They also support integration with asset tracking or maintenance systems through barcodes and QR codes.

With custom pipe labeling, facilities can:

-

Improve visibility with color-coded and content-specific messaging

-

Reduce confusion during emergencies or shift changes

-

Add barcodes, QR codes, or safety symbols for clarity and tracking

-

Support specialized workflows with unique text fields or multilingual options

Custom labeling improves visual communication, reduces ambiguity, and reinforces accountability across departments. It’s a scalable solution that meets the evolving needs of modern facilities while directly addressing the hazards of unmarked pipes.

Building a Pipe Marking Plan That Works

Effective pipe marking starts with a structured plan that aligns labeling practices with safety, maintenance, and regulatory goals.

1. Conduct a Pipe Identification Audit

Begin with a full review of your facility’s pipe marking and labeling systems. Identify what each line contains, where it flows, and whether any labels are missing, damaged, or outdated. Pay special attention to systems involving steam, chemicals, or pressurized materials.

2. Follow ANSI/ASME Labeling Standards

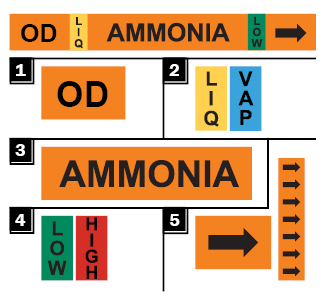

Use industry standards as the foundation for your labeling strategy. ANSI/ASME A13.1 provides clear guidance on:

-

Label placement and flow direction indicators

-

Letter height requirements based on pipe diameter and viewing distance

-

Color combinations that signal pipe contents (e.g., water, steam, ammonia)

-

Consistency across departments and contractors

Applying these standards consistently improves comprehension across teams and ensures compliance.

3. Streamline Production with Pipe Marker Label Software

Manual labeling approaches often lead to inconsistency and rework. With dedicated pipe marker label software, teams can produce compliant, standardized labels in less time. Software tools offer templates, color libraries, and editing features that help eliminate guesswork and reduce human error.

LabelForge PRO: Smarter Software for Safer Pipe Marking

For facilities seeking a streamlined, scalable solution, LabelForge PRO Design Software provides purpose-built tools for industrial labeling. This powerful pipe marker label software enables teams to create, edit, and print custom pipe markers that align with ANSI/ASME standards and facility-specific needs.

For facilities seeking a streamlined, scalable solution, LabelForge PRO Design Software provides purpose-built tools for industrial labeling. This powerful pipe marker label software enables teams to create, edit, and print custom pipe markers that align with ANSI/ASME standards and facility-specific needs.

LabelForge PRO includes preloaded templates, compliance-ready symbols, and intuitive controls that make it easy to update or expand your labeling system without slowing operations. The software supports custom layouts and content fields, so your team can build exactly the pipe labels they need—whether they’re dealing with chemical transfer lines, high-pressure steam, or facility-specific utility systems.

Key features of LabelForge PRO include:

-

Built-in ANSI/ASME-compliant templates for pipe marking

-

Drag-and-drop design tools for quick, consistent layout creation

-

Custom label fields to include flow direction, hazard details, or multilingual content

-

A searchable symbol library with GHS, PPE, and safety signage icons

-

Seamless compatibility with DuraLabel’s industrial printers and labeling supplies

Whether you’re labeling new installations or correcting outdated markers, LabelForge PRO simplifies every step of the process—helping your team maintain accurate pipe identification across the facility.

Maintaining an Effective Pipe Marking System

Labeling is not a one-time task. Over time, labels can fade, peel, or be obscured by insulation, debris, or equipment modifications. When processes change or systems are upgraded, labels must be updated to reflect new conditions.

To keep your facility in compliance and avoid the hazards of unmarked pipes, incorporate labeling checks into routine maintenance schedules. Keep your pipe marker label software records current, and empower teams to flag and resolve issues before they become safety incidents. A proactive approach to pipe identification ensures your labeling system continues to protect workers and support operational clarity.

Download LabelForge PRO and Strengthen Your Pipe Marking Program

Inaccurate, missing, or poorly maintained pipe labels put workers and operations at risk. LabelForge PRO gives your team the tools to create compliant, consistent, and durable pipe markers that improve safety and meet ANSI/ASME standards.

With built-in templates, color-coded formatting, and an intuitive interface, LabelForge PRO simplifies even the most complex pipe marking tasks. It’s designed to help teams label everything from steam and ammonia lines to LNG systems with speed and accuracy.

DuraLabel also offers a wide range of premade pipe markers for common pipe contents and applications. For unique systems or site-specific needs, create custom pipe labels using LabelForge PRO and tailor every label to your exact requirements.

Developed by DuraLabel and trusted across critical industries, LabelForge PRO works seamlessly with DuraLabel Industrial Sign and Label Systems to support safe, efficient pipe identification in any environment.

Download LabelForge PRO now to build a safer facility and prevent the hazards of unmarked pipes before they lead to costly incidents.

Still have questions? Call 1-888-411-3520 to speak with a DuraLabel expert about building or upgrading your pipe marking system.

Read Next:

Why Electrical Engineers Need LabelForge PRO for Consistent Compliance

How UltraPure Systems Leveraged DuraLabel Pipe Labels for Compliance

Related Resources

Understanding the ASME A13.1 Standard for Enhanced Pipe Labeling

Pipe marking quickly communicates essential information to everyone in a facility, improving overall ...

Read

How Sun Exposure Affects Pipe Labels

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and ...

Read

The Dangers of Abandoned Pipes

Whether a pipe contains chemicals, water, or nothing, it's important to know if it's hazardous. ANSI/ASME ...

Read.png)