Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary?

An arc flash protection boundary defines the minimum safe distance from energized equipment where workers could be exposed to arc energy levels capable of causing second-degree burns. This critical safety concept, outlined in NFPA 70E, helps determine how close personnel can safely work during electrical maintenance or inspection.

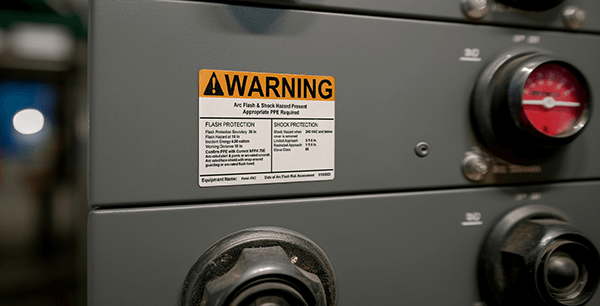

Within this boundary, proper arc flash protection measures—such as labeling, PPE, and procedural controls—are essential to reduce risk. Clear, compliant arc flash labels communicate incident energy, voltage, and boundary distances, allowing workers to recognize hazards before approaching equipment.

Main Arc Flash Categories

There are four recognized arc flash categories, each defined by how energy is released and the conditions in which it occurs. Understanding these types helps determine the correct labeling, PPE, and response strategy. To reduced risk, employees must be trained to recognize arc flashes to and follow established safety protocols through regular instruction and drills. Below is a breakdown of the four recognized types and the conditions under which they typically occur:Open-Air Arc Flash

An open-air arc flash occurs when electrical current arcs through the air between exposed conductors, such as wires or equipment. This is the most widely recognized and studied type of arc flash. It’s often used in lab testing to model arc flash behavior and calculate incident energy.

Common causes include equipment failure, poor maintenance, and human error. Because it’s frequently encountered in real-world industrial settings, this category forms the basis for many safety standards and label requirements.

Arc-in-a-Box

An arc-in-a-box flash occurs when the arc is confined within an enclosure—such as a panel box—where pressure and energy are concentrated. This model is commonly used in EU safety testing but offers valuable insight for all electrical systems.

While less frequently seen in daily operations, this category helps safety professionals understand how enclosure design and containment influence arc flash behavior.

Ejected Arc

An ejected arc occurs when high-energy plasma is violently expelled from the arc source, making direct contact with personnel. It typically results from high-voltage conditions (480V and above) and represents one of the most dangerous forms of arc flash due to the speed and unpredictability of plasma movement.

Although not always accounted for in standardized calculations, this real-world hazard reinforces the importance of robust labeling and PPE requirements.

Tracking Arc

Tracking arcs occur when arc plasma travels across a surface—such as a worker’s skin or clothing—rather than jumping through open air. This type is more common at very high voltages or in situations involving contamination or insulation failure.

While less visible, tracking arcs pose serious burn and shock risks and further illustrate the need for vigilance, proper gear, and environment-specific labeling

What Information Goes on an Arc Flash Label?

Arc flash labels must include specific, actionable safety data. According to NFPA 70E and OSHA guidelines, the minimum required information includes:

-

Nominal system voltage

-

Incident energy (cal/cm²)

-

Arc flash boundary

-

Required PPE category or rating

-

Equipment identification

-

Date of label issue or analysis

Labels should be placed on any panel or piece of equipment where energized work may be performed. Inconsistent or missing labeling is a common cause of arc flash injuries and a major compliance red flag.

Arc flash warning label examples often show how to structure these details using standardized formatting and ANSI/ISO-compliant icons.

What Are the Best Practices for Arc Flash Safety?

Arc Flash labels are a critical part of A layered electrical safety system. While PPE and lockout/tagout (LOTO) protocols are essential, labels are the only passive control that continuously communicates risk, even when no one is present. Their visibility at the point of hazard helps reinforce safer behavior, support compliance, and prevent costly mistakes.

Preventing arc flash incidents requires a proactive, real-world safety strategy that goes beyond theoretical models.

Although open-air arc and arc-in-a-box scenarios are typically used in lab testing and safety calculations, actual jobsite conditions often involve less predictable and more hazardous risks of ejected and tracking arcs, especially at higher voltages.

To protect workers, employers must implement training programs, that often include strict adherence to procedures, and the consistent use of NFPA 70E-compliant PPE. These safety measures, paired with clearly visible arc flash labels, help ensure your facility has the best safeguards in place.

Electrical Safety Tips

Every facility should adopt standardized electrical safety procedures. The following best practices reduce the likelihood of arc flash events and ensure compliance with OSHA and NFPA standards:

- Always assume that electrical equipment is energized unless confirmed otherwise through proper lockout/tagout procedures.

- Wear appropriate PPE, including arc-rated clothing, gloves, and face shields based on NFPA 70E PPE levels.

- Use insulated tools and equipment to reduce the risk of accidental contact with energized parts.

- Follow established safety protocols and procedures when working on or near electrical equipment.

- Conduct regular inspections of electrical enclosures to identify any signs of damage, contamination, or insulation degradation.

- Ensure that electrical equipment is properly rated for its intended use and that enclosure doors are securely closed and latched.

- Implement proper ventilation and pressure relief mechanisms to minimize the buildup of pressure during an arc flash event.

- Implement regular maintenance and testing of electrical systems to identify and address potential issues before they lead to arc flash incidents.

- Use circuit protection devices, such as fuses and circuit breakers, rated for specific application and load requirements.

- Train personnel on emergency procedures, including evacuation routes and the use of fire suppression equipment.

DuraLabel Arc Flash Resources

Arc flash safety doesn’t need to be complicated. With the right labeling solutions, you can meet NFPA 70E and OSHA requirements, improve hazard communication, and protect your team—without overcomplicating your workflow.

DuraLabel Industrial Sign and Label Systems and LabelForge® PRO design software are built for high-performance electrical environments. Use compliant arc flash labels to identify voltage levels, PPE categories, and approach boundaries. Leverage color-coded signage and standardized layouts to reinforce your training programs and support safer decision-making at every panel.

DuraLabel’s free Arc Flash Labeling Quick Start Guide helps teams create OSHA-compliant arc flash labels, implement lockout/tagout procedures, and select the appropriate NFPA 70E PPE levels for each task. Whether you're building a new program or improving an existing one, this guide offers step-by-step support to simplify your safety efforts. Download our free guide today.

Looking to go beyond arc flash? Explore DuraLabel’s free Facility Signage Handbook. Your go-to resource for implementing effective visual communication across your site. This free guide includes full-color floor plan examples, real-world arc flash warning label examples, and customizable signage strategies to help streamline your facility’s safety workflows.

Still not sure where to start? Contact us today at 1-888-897-5580 to speak with a DuraLabel safety professional who can help tailor a labeling solution to your unique environment.

Read Next:

Arc Flash Labeling Essentials for Industrial Facilities & Field Teams

Related Resources

5 Shocking Arc Flash Mistakes

Everyone knows arc flash is dangerous and the hazards that come with electrical work. However, sometimes ...

Read

How to Improve Arc Flash Hazard Safety in Mining Operations

How Can Mining Teams Reduce the Risk of Arc Flash Hazards? Mining operations depend heavily on electrically ...

Read

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA’s Standard for Electrical Safety in the Workplace, outlines specific ...

Read.png)