Industry

Manufacturing

Challenge

DSM-Firmenich's Brady system was frustrating and inefficient, offering limited label options and complex setup. As labeling needs grew, the system failed to meet the demand for clear, consistent labels essential for compliance and safety.

Results

With the DuraLabel Toro Max, DSM-Firmenich improved labeling efficiency and clarity for enhanced safety and compliance. The streamlined workflow freed up time for more strategic tasks, allowing the team to meet goals with greater confidence and professionalism.

“Our old Brady system was a pain.”

Jeff Goodin

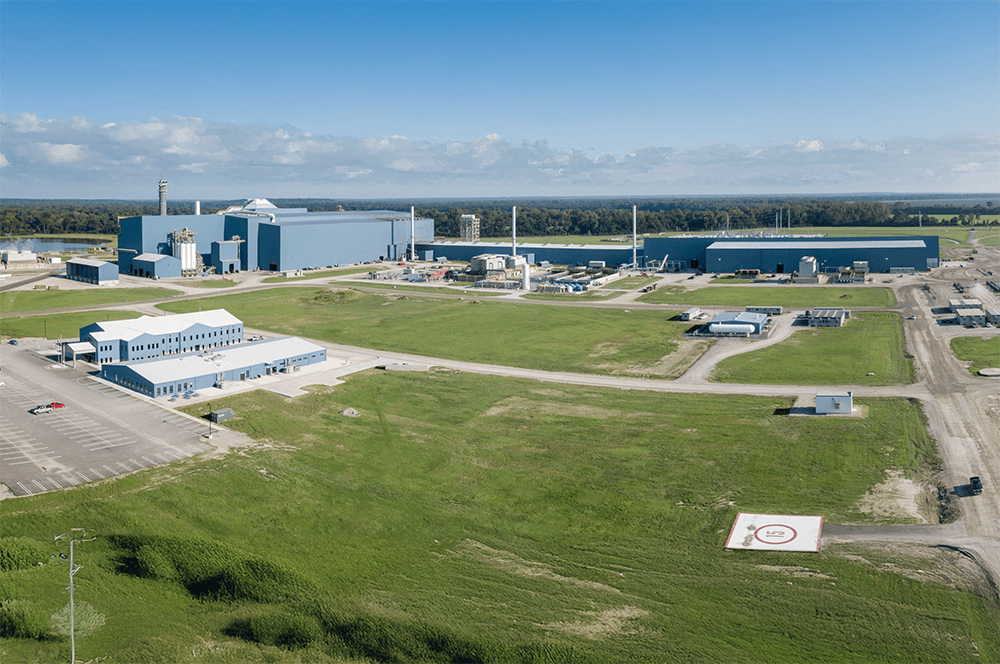

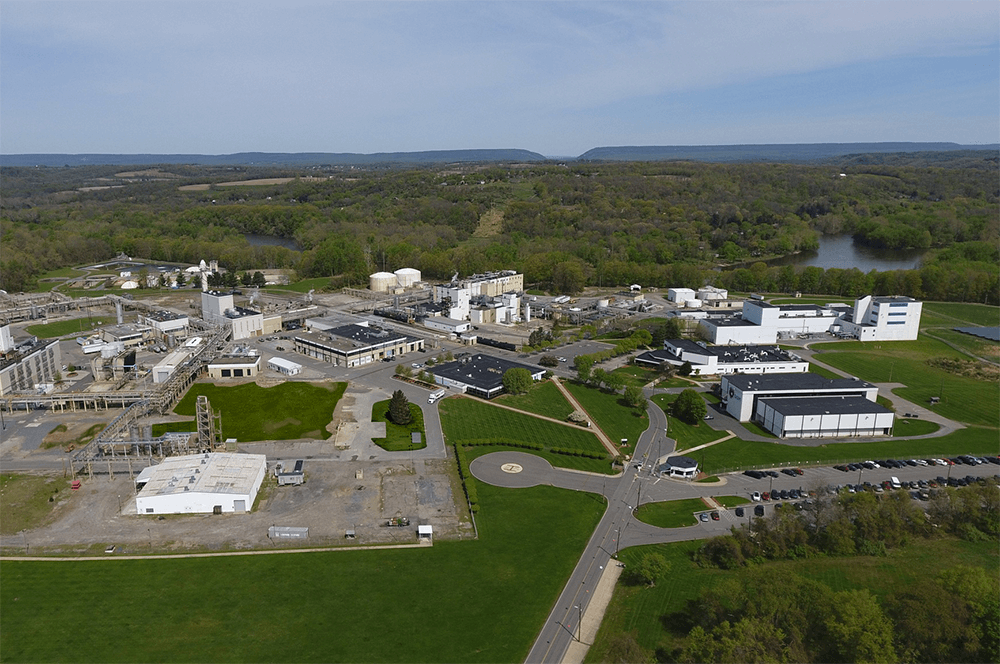

DSM-Firmenich is a global leader in health, nutrition, and bioscience. DSM is committed to creating sustainable, innovative solutions that improve health and safety worldwide. Within its complex operations, maintaining consistent, compliant labeling for equipment and systems is crucial for safety and regulatory adherence. Jeff Goodin, the Team Lead for Instrumentation and Electrical (I&E), oversees the labeling processes to ensure every area remains organized and safe for workers. DuraLabel partnered with DSM-Firmenich, providing a reliable Toro Max Industrial Sign and Label Print System—and other print systems—to support these critical needs.

DSM-Firmenich is a global leader in health, nutrition, and bioscience. DSM is committed to creating sustainable, innovative solutions that improve health and safety worldwide. Within its complex operations, maintaining consistent, compliant labeling for equipment and systems is crucial for safety and regulatory adherence. Jeff Goodin, the Team Lead for Instrumentation and Electrical (I&E), oversees the labeling processes to ensure every area remains organized and safe for workers. DuraLabel partnered with DSM-Firmenich, providing a reliable Toro Max Industrial Sign and Label Print System—and other print systems—to support these critical needs.

The Challenge

For nearly two decades, DSM-Firmenich relied on a legacy Brady system that brought frequent frustrations and inefficiencies. Jeff and his team found the outdated system inefficient, with limited label options and difficult setup. “Our old Brady system was a pain,” Jeff shared, highlighting the delays caused by its complicated design. As the team’s needs expanded, particularly for labeling in compliance and pipe marking, they recognized that their existing system lacked the flexibility and ease of use needed to keep pace with the growing demand. Clear, consistent labeling was key for keeping up with regulations and ensuring team safety, which made upgrading a top priority.

The Solution

DSM-Firmenich found the ideal solution with DuraLabel’s Toro Max Print System. With Toro Max’s high-quality output, straightforward setup, and broad range of labeling options, Jeff and his team could streamline their labeling process efficiently. “It was very easy to use, and my sales support is awesome,” Jeff noted.

The Toro Max Print System offered versatile applications, from compliance labeling to pipe marking, all while producing durable, high-visibility labels tailored to DSM-Firmenich’s safety and regulatory standards. The system’s ease of use enabled the team to integrate it seamlessly without complications, eliminating the challenges they had faced with their previous Brady printer.

“It was very easy to use, and my sales support is awesome." - Jeff Goodin

The Results

Since implementing DuraLabel Toro Max, DSM-Firmenich has achieved increased efficiency and clarity in labeling across the facility. The improved line identification and compliance labeling have made operations smoother for a safer work environment and adherence to safety standards. Jeff reported that the Toro Max Print System has significantly enhanced his team’s workflow, which freed up time and resources for more strategic tasks. Summing up the positive impact, Jeff said, “It has made me the envy of all I survey.” Thanks to DuraLabel’s reliable support and high-performance print system, DSM-Firmenich continues to meet its objectives with confidence and professionalism.

.png)