What is Pipe Marking

What's Pipe Marking?

Video Transcription

Pipes, lines, tubing, conduits while the terminology varies, the problem is always the same: Workers, site visitors and emergency responders all need to know what's in those pipes.

The solution is pipe marking.

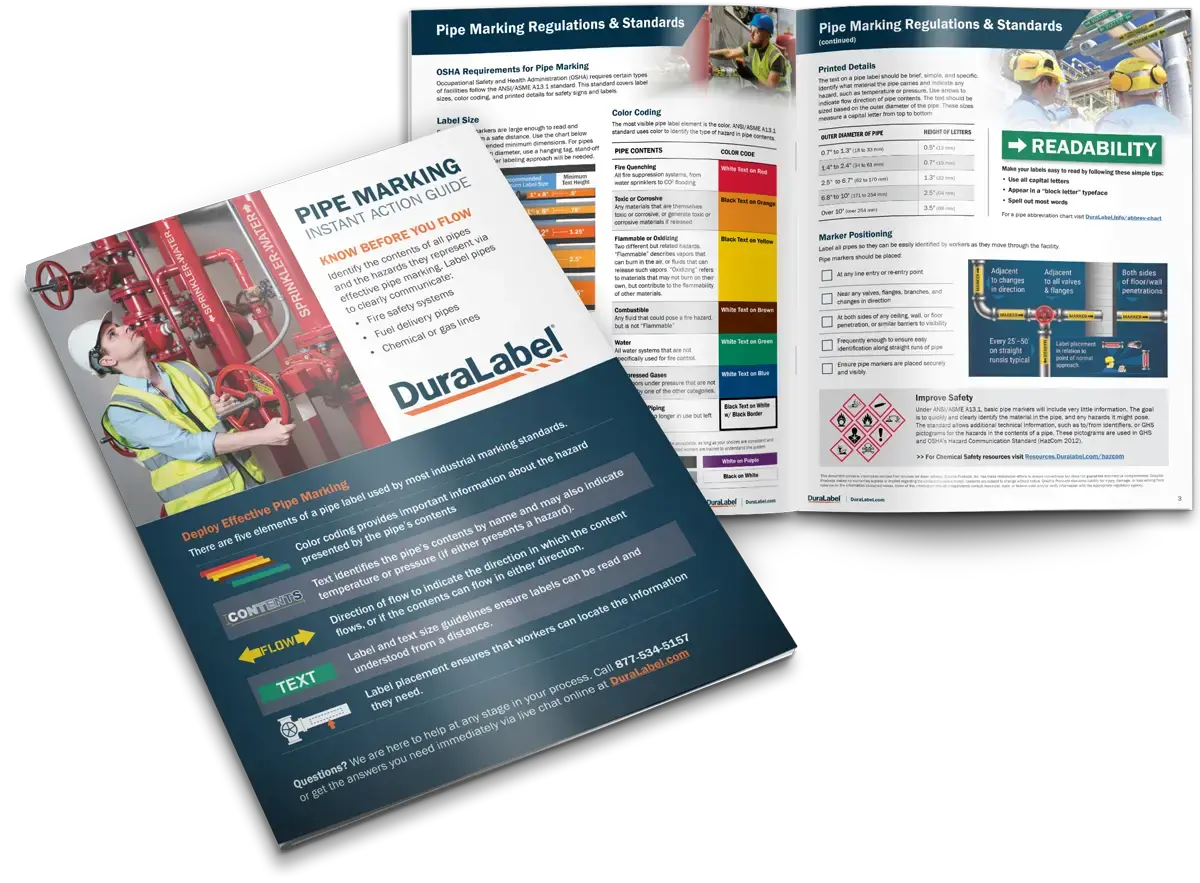

Always check with local authorities on your area's exact regulations as there are dozens of standards for pipe marking and they range widely in applicability, popularity and legal requirements. The most widely accepted are the ANSI/ASME A13.1 standard.

Created in 2007, the current standard blends existing ANSI and ASME guidelines.

Now, which pipes need to be marked? Ideally, all pipes in a facility are properly labeled, but the ANSI / ASME standard outlines three categories specifically that require identification:

- Pipes with hazardous contents or contents that could generate hazardous conditions.

- Pipes that could affect the procedures followed during an emergency or that are part of hazard prevention, emergency response or serve a safety purpose.

- Pipes' whose flow must be redirected, shut off, or adjusted to allow for maintenance or other expected work.

When it comes to marking these pipes, it's important to quickly know what they contain, so the ANSI / ASME standard uses this color code to identify pipes by the general kinds of materials they contain.

The A13.1 standard also state that the text, or "legend" is the most important element on the label. When designing a label, the size of both label itself and the text is determined by the (OD) or outer diameter of the pipe being marked. For example, any pipe with an 8 to 10 inch outer diameter should have a label sizing at least 3 by 24 inches, with text at least 2.5 inches tall. This ensures that the marking is clearly visible.

For an in-depth look at the ANSI/ASME pipe marking standard, or to find out how to evaluate and update your facilities' pipe marking system-follow the link, fill out the form and receive your free copy of our Pipe Marking Best Practice Guide.

Additional Resources:

• Free Pipe Marking Best Practice Guide

Related Resources

How to Make an Ammonia Pipe Marker

In this video, learn how to print ammonia pipe markers using the DuraLabel Toro Max. We walk you through the ...

Watch Now

IIAR Pipe Marking Labels

What are IIAR Pipe Marking Labels? Video Transcription Is this label compliant? How do you know? Can you ...

Watch Now.webp)

Pipe Marking Sizing Guide

Feeling overwhelmed by the maze of pipes in your facility? You’re not alone! Pipe marking is crucial for ...

Watch Now.png)