Lean Green Manufacturing: How 5S Methods Enhance Sustainability

Manufacturing industries face pressure from both the public and private sectors, each demanding faster, cheaper, and higher-quality products with the lowest environmental impact. Cap-and-trade emissions policies, paired with limited natural resources, have reshaped modern industry.

As a result, lean companies, particularly those with established 5S in green manufacturing systems, are ahead of the curve in meeting these challenges by reducing waste, improving efficiency, and embracing sustainable production methods. For instance, the automotive industry has seen a significant shift towards sustainable practices, with companies like BMW constructing green plants in Leipzig, Germany, to minimize environmental impact.

"Lean initiatives work well with green initiatives because you're looking at costs and how much waste is in the process," said Michael Sinocchi, executive editor with Productivity Press, a publishing company in New York. Productivity Press, founded more than 20 years ago, has translated the works of leading Japanese industrial experts on the Toyota Production System (TPS), which forms the basis of the lean and sustainable manufacturing strategy.

"With lean, the goal was to drive waste out of the process and invest those savings into the product by charging customers less, having shorter lead times, and spending less on inventory," Sinocchi said. "Now, it's driven by demand and resources."

By integrating 5S for reducing waste into manufacturing processes, organizations can align their sustainability goals with operational improvements. Sustainable manufacturing with 5S provides clear environmental benefits, enabling companies to adopt green practices in 5S systems, enhance resource efficiency, and reduce their overall ecological footprint. Implementing 5S and other lean methodologies has led companies like KAPCO to enhance operational efficiency and optimize processes, demonstrating the tangible benefits of these practices.

What Is Green Manufacturing?

Green manufacturing takes lean principles a step further by focusing on the environmental impact of production processes and materials. The correlation between companies that implement lean manufacturing and those adopting green manufacturing is strong, as both emphasize reducing waste, conserving energy, and improving efficiency. These efforts closely align with the principles of 5S, a system designed to optimize workplace efficiency through five key pillars: Sort, Set in Order, Shine, Standardize, and Sustain. Incorporating these 5S pillars into green manufacturing practices helps businesses meet regulatory requirements, achieve sustainability goals, and maintain consistent operational improvements.

The 5S pillars include:

-

Sort: Remove unnecessary items from each area.

-

Set In Order: Organize and clearly identify storage for efficient use.

-

Shine: Regularly clean and inspect each area to maintain safety and efficiency.

-

Standardize: Integrate 5S principles into standard operating procedures.

-

Sustain: Assign responsibility, track progress, and ensure continuous improvement.

Federal agencies such as the Environmental Protection Agency (EPA) have studied the relationship between 5S and green manufacturing. The EPA reports that companies using 5S systems experience multiple environmental benefits, including:

- Energy Conservation: Painting machines and equipment in light colors and cleaning windows, an aspect of the Shine pillar, decreases the energy needed for lighting, contributing to sustainable manufacturing with 5S.

- Waste Reduction: Regular cleaning allows workers to detect spills or leaks quickly, significantly decreasing spill response time and reducing waste generated from cleanup.

- Accident Prevention: Similar to the focus on medical facility 5S safety, removing obstacles and clearly marking main thoroughfares minimizes the potential for accidents that could result in hazardous waste generation, including spilled materials and absorbent clean-up supplies. This is a core component of lean and sustainable manufacturing.

- Defect Prevention: Keeping workspaces clean and organized under the Shine pillar reduces the accumulation of shavings, dirt, and debris that can contaminate production processes. Fewer defects mean fewer wasted materials and less energy spent on rework.

- Space Optimization: By sorting and eliminating unused equipment and supplies, companies using 5S in green manufacturing can significantly reduce their required operational footprint. Less storage space translates into reduced energy consumption for heating and lighting.

- Material Efficiency: Organizing equipment, parts, and materials improves accessibility and encourages employees to use existing resources before ordering more, reducing unnecessary chemical and material waste.

- Enhanced Visual Communication: Using 5S visual cues—such as signs, placards, scoreboards, and laminated procedures—enhances employees' understanding of proper waste handling, workplace hazards, and emergency response protocols. Green practices in 5S systems improve labeling of hazardous materials and streamline disposal procedures.

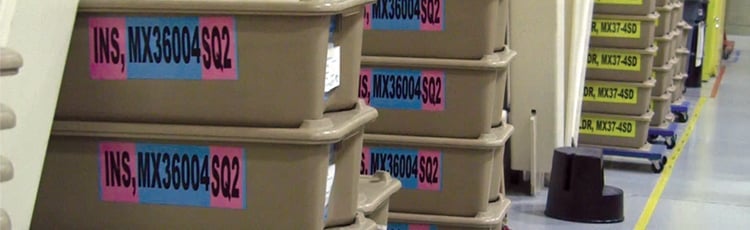

- Environmental Management: Integration with 5S operating procedures ensures that tools and materials are properly stored in labeled, color-coded locations. Utilizing "kits" that contain only the necessary material for a task helps eliminate overuse and supports 5S for reducing waste.

Examining Waste Beyond the Workspace

When green manufacturing is combined with 5S best practices, companies gain visibility not only into workspace efficiency but also into the entire lifecycle of their products. This broader approach encourages businesses to analyze the long-term impact of their production methods and make strategic adjustments for sustainability. A study published in the Science of the Total Environment journal proposed the lean energy-saving and emission-reduction (LESER) approach to improve energy efficiency and reduce waste emissions in manufacturing processes.

"Initially, companies were only focused on the front end of a product—how to be the best, the cheapest, and the fastest to get it out the door to sell it," Sinocchi said. "Now, companies are looking at the overall life of the product: what environmental impact it has and whether the same production resources will be available 10-15 years from now."

Sinocchi pointed to electric vehicles (EVs) as an example. When Ford introduced its first electric car, Toyota had already launched the Prius 2, positioning itself as an early leader in sustainable transportation.

"Companies like Ford were waiting for customer demand," he said. "Toyota examined the cost of resources like oil and realized this market will change 10-15 years from now. Companies can either sit back and say something will change or actively plan for it."

Next Steps for Sustainable Manufacturing with 5S

As more companies recognize the value of 5S in green manufacturing, they can integrate these principles into their sustainability roadmaps. The implementation of 5S for reducing waste not only improves operational efficiency but also enhances a company's ability to meet environmental regulations and industry expectations. The EPA's Lean and Environment Toolkit provides practical techniques for integrating environmental considerations into lean initiatives, helping companies achieve both operational efficiency and environmental sustainability.

For those looking to adopt these strategies, Productivity Press provides valuable resources on 5S and green manufacturing. Visit the Productivity Press website for recommended reading, including:

- The Green Factory: Creating Lean and Sustainable Manufacturing

- Creating a Lean and Green Business System: Techniques for Improving Profits and Sustainability

- Lean Waste Stream: Reducing Material Use and Garbage Using Lean Principles

Additionally, for step-by-step guidance on implementing 5S in your green manufacturing facility, download our free 5S Best Practice Guide to ensure you leverage sustainable manufacturing with 5S effectively.

By taking proactive steps now, companies can position themselves for long-term success while meeting sustainability goals and driving operational excellence.

Related Resources

What Is Lean Manufacturing

Lean is an efficient approach to running a process, business or organization to minimize waste, lower lead ...

Read

Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter? Lean manufacturing principlesare core ...

Read

How to Improve Quality Control in Manufacturing with Lean and 5S

What Is Quality Control in Manufacturing? Quality control in manufacturing is the process of monitoring and ...

Read.png)