6 Industrial Labeling Mistakes to Fix Before Year-End Audits

What Are the Most Common Industrial Labeling Errors That Can Cost Facilities During Audits?

As facilities prepare for year-end audits, one area often overlooked is industrial labeling. Small mistakes, such as faded hazard labels, missing symbols, or inconsistent layouts, can lead to compliance violations under OSHA, GHS, and ANSI standards.

These issues weaken safety communication, delay inspections, and increase the likelihood of costly citations, but they can be corrected quickly with consistent, compliant labeling practices.

Six common industrial labeling mistakes:

- Non-compliant label formats

- Label durability issues

- Environmental labeling challenges

- Inconsistent GHS and ANSI labels

- Outdated or damaged labels

- Delayed label updates

Addressing mistakes early helps facilities stay compliant and maintain professional, audit-ready labels across every department.

1. Non-Compliant Formats That Violate OSHA Label Compliance

Many facilities still use outdated templates or generic designs that fail to meet OSHA label compliance requirements. Missing signal words, incorrect colors, or inconsistent fonts can result in immediate audit deductions.

According to OSHA 1910.145 and ANSI Z535 standards, labels must include clear signal words like Danger, Warning, or Caution, combined with appropriate colors and symbols.

With built-in OSHA and ANSI templates, DuraLabel®’s free LabelForge® PRO Design Software simplifies industrial labeling and eliminates formatting errors.

2. Poor Durability That Jeopardizes Audit-Ready Labels

A label that fades, smudges, or peels won’t pass inspection—even if it’s formatted correctly. Harsh environments can quickly degrade low-quality materials.

Common causes of premature label failure include:

- Exposure to UV light that causes fading and discoloration

- Contact with solvents or cleaning agents that break down adhesives

- Abrasion from equipment or frequent handling

- Heat fluctuations that cause peeling or curling

- Using the wrong adhesive type for textured or oily surfaces

DuraLabel’s tough-tested supplies are engineered for longevity, undergoing exposure to heat, solvents, and abrasion during testing. For example, premium vinyl and polyester label stock remain legible in environments reaching 300°F or when exposed to industrial cleaners.

By choosing long-lasting materials, facilities protect their audit-ready labels and avoid costly reprinting or compliance failures during inspections.

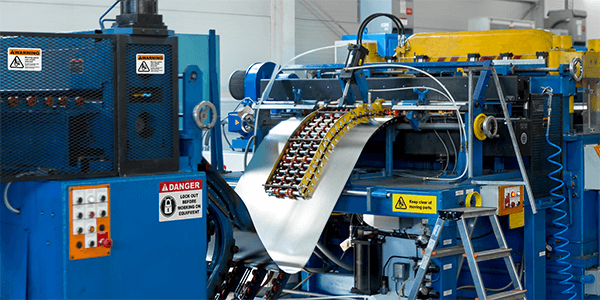

3. Ignoring Environmental Factors in Industrial Labeling

Every facility environment introduces unique labeling challenges. High humidity, dust, or chemical exposure can affect adhesion and clarity. Ignoring these variables leads to label failure and potential OSHA citations.

Facilities in chemical plants or refineries should use chemical-resistant vinyl, while outdoor equipment may require UV-resistant reflective materials for readability in all conditions.

A strong industrial labeling program accounts for these environmental differences from the start, keeping safety messages visible no matter the conditions.

How Internal Audits Strengthen Industrial Labeling Programs

Internal safety audits give teams a chance to uncover labeling gaps before external inspectors arrive. By walking through production areas, safety managers can identify missing hazard signs, outdated GHS labels, or worn arc flash markers.

These internal reviews also help departments coordinate their compliance efforts. Maintenance, operations, and safety teams can align their templates, label materials, and documentation practices under a unified industrial labeling standard.

This proactive approach demonstrates continuous improvement and creates stronger audit-ready labels long before the official inspection takes place.

4. Inconsistent GHS and ANSI Labeling Across Departments

When maintenance, operations, and safety teams each create labels using different designs, it undermines compliance and confuses auditors. Consistency is key to credibility.

Centralized software such as LabelForge PRO eliminates mismatched templates by standardizing color codes, GHS pictograms, and hazard formatting across departments. This unified approach supports GHS and ANSI labeling requirements while promoting clear, recognizable communication.

During an audit, consistent visuals send a clear signal that the facility follows structured, proactive labeling management.

Common Oversights in GHS and ANSI Labeling Reviews

Even well-organized facilities can miss subtle compliance details. Common oversights include incorrect hazard pictograms, improper color contrast, or missing secondary container labels.

Another frequent issue is outdated GHS information, such as old hazard statements or misclassified chemicals, remaining on containers long after updates to Safety Data Sheets (SDS).

Regularly reviewing GHS and ANSI labeling ensures that visual communication stays accurate as standards evolve. When paired with reliable industrial labeling software, teams can correct these minor errors before they turn into major audit findings.

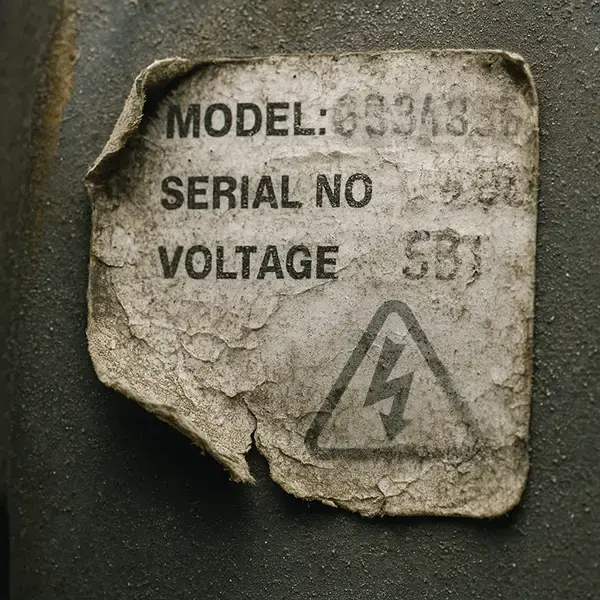

5. Damaged or Outdated Labels That Violate OSHA Label Compliance

One of the first things auditors notice is damaged or expired labels. A single illegible arc flash or chemical hazard label can trigger noncompliance findings under OSHA label compliance or NFPA 70E.

Before inspections, facilities should verify the condition of:

- Electrical panel and arc flash labels

- Chemical and GHS hazard communication labels

- Pipe markers under ANSI/ASME A13.1

- Machine and floor safety signage

Teams that print replacements in-house with a DuraLabel Toro® Max printer maintain a steady supply of durable, audit-ready labels that meet every standard on short notice.

The Role of On-Demand Printing in Maintaining Audit-Ready Labels

On-demand printing provides unmatched flexibility in managing label updates. Instead of waiting for outsourced orders, teams can produce compliant labels in minutes.

With a reliable industrial sign and label printer, staff can reprint worn hazard signs, update GHS information, or add barcode identifiers instantly. This adaptability keeps industrial labeling programs current, supports rapid compliance updates, and helps facilities stay ready for surprise audits or internal safety reviews.

6. Delayed Updates That Compromise GHS and ANSI Labeling

Whenever equipment changes, chemicals are introduced, or production lines shift, labels must be updated immediately. Waiting until audit time often results in compliance gaps.

Facilities using a DuraLabel Toro Max printer can create and update compliant labels the same day changes occur. This capability helps maintain real-time accuracy for GHS and ANSI labeling.

Proactive labeling updates demonstrate continuous compliance and minimize last-minute rushes that increase the risk of mistakes.

Building an Audit-Ready Labeling Program That Lasts

The most successful facilities treat industrial labeling as an ongoing safety program. An effective system is built on three principles:

- Compliance: Follow OSHA, GHS, and ANSI standards for design, color, and visibility.

- Consistency: Use unified templates and materials throughout the organization.

- Durability: Select durable supplies that withstand heat, moisture, and chemicals.

With DuraLabel’s integrated hardware and software, teams can audit their visual communication system anytime—ensuring every message is clear, compliant, and ready for inspection.

When auditors arrive, accurate, audit-ready labels speak for themselves.

DuraLabel Products and Resources for Industrial Labeling

Preparing for audits is easier when labeling systems are organized, consistent, and built for long-term performance. Investing in reliable tools helps facilities keep every label compliant, legible, and ready for inspection. That’s where DuraLabel products make the difference—offering durable materials and intuitive printing systems that simplify compliance and strengthen workplace safety communication.

The DuraLabel Toro Max Industrial Sign and Label System makes professional industrial labeling fast and reliable. Its built-in touchscreen and rugged portability allow teams to print compliant signs and labels directly where needed. Paired with durable vinyl and polyester supplies, Toro Max helps facilities maintain audit-ready labels and consistent visual communication in any environment.

Get ready for your next inspection with DuraLabel’s OSHA Signage Quick Start Guide. This free resource outlines label color codes, placement rules, and best practices for maintaining OSHA label compliance throughout your facility.

Need guidance before your audit? Call 1-888-786-9223 to connect with a DuraLabel expert who can recommend labeling systems, supplies, and software to keep your operation compliant and efficient.

Read Next:

How to Improve Fire Safety with Custom Labels and Signs

How Does an End-of-Year Signage Audit Improve Workplace Safety?

Related Resources

When Facilities Should Upgrade an Industrial Label Printer

When Should You Upgrade Your Industrial Label Printer? Facilities should upgrade an industrial label printer ...

Read

Industrial Labeling Trends Driving Facility Compliance Forward

How Are IndustrialLabeling Trends Shaping Safety and Compliance? Industriallabeling trendsare shifting ...

Read

Why Engineers Rely on LabelForge PRO for OSHA Electrical Safety

What Is LabelForge PRO and What Is It Used For? DuraLabel LabelForge® PRO Design Software is an industrial ...

Read.png)