How to Audit OSHA-Compliant Signs Before the New Year

How Does an End-of-Year Signage Audit Improve Workplace Safety?

An end of year signage audit improves workplace safety by confirming your OSHA compliant signs are still clear, accurate, and aligned with current procedures. It helps catch faded, missing, or outdated OSHA signs so employees are not relying on partial or outdated visual cues. Correcting those issues strengthens compliance and reduces preventable incidents.

The sections below explain what to review during an audit, what problems show up most often, and how to correct them.

-

Why end of year audits reduce risk

-

The most common failures in OSHA signs

-

What to check for OSHA compliant signs

-

How to prioritize replacements and updates

-

Resources that make audits faster

As the year winds down, an end of year signage audit helps facilities close safety gaps before they turn into hazards. It ensures signs remain clear, up to date, and aligned with procedures. Faded or outdated visuals create hidden risks, but addressing them now prevents disruptions and reinforces compliance for the year ahead.

Facilities can simplify the process with the free Facility Signage Handbook. This resource outlines how to use a safety signage audit checklist, select compliant safety labels, and replace faded safety signs. Applying it during an end-of-year signage audit makes it easier to spot gaps and keep signage aligned with current standards.

Recognizing Faded OSHA Signs and Outdated Workplace Signage

The first step in an audit is to check the condition of signage. A year’s worth of sunlight, moisture, chemicals, and daily contact can quickly reduce effectiveness.

Facilities should look for the following issues during an end-of-year signage audit:

- Faded Safety Signs: Graphics washed out by UV rays or cleaning chemicals.

- Outdated Workplace Signage: Warnings or instructions that no longer match current procedures or regulations.

- Peeling or Curling Edges: Adhesives weakened by heat or moisture.

- Cracks, Dents, or Abrasions: Damage from heavy equipment or forklift traffic.

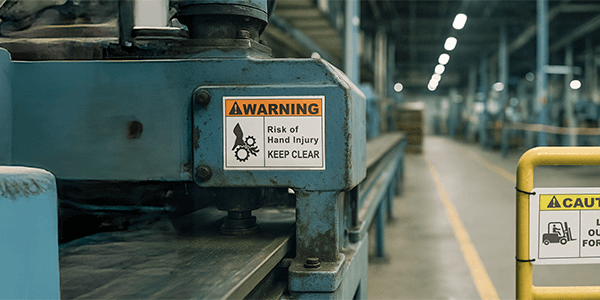

These problems may seem minor, but they can undermine safety systems. A forklift lane with faded arrows creates confusion about traffic flow. A chemical storage sign missing its hazard pictogram puts workers at risk. Findings like these show why replacing safety signs is a necessary step before the new year.

Meeting OSHA Signage Requirements and Maintaining Compliance

Condition is important, but compliance is essential. OSHA signage requirements under 1910.145 mandate clear visibility and distinctive colors, while ANSI standards specify layout and signal words. Compliant safety labels also help reduce variability and reinforce consistent hazard communication.

For chemical facilities, durable workplace signage built to GHS standards is critical. Labels must withstand solvents, moisture, and temperature shifts. An end-of-year signage audit helps prevent citations, avoid last-minute fixes, and strengthen workplace signage compliance.

How End-of-Year Audits Strengthen Workplace Signage Compliance

An end-of-year signage audit is also a key operational advantage. Clear, well-maintained signs reduce confusion and allow workers to act quickly in busy environments. For example, a warehouse with intact “Inbound” and “Outbound” markings keeps forklifts moving safely, while in healthcare, a fresh “Isolation Room—PPE Required” sign protects staff and patients.

This is also the right time to check placement. Has an “Emergency Exit” sign been blocked by stored equipment? Is a “Hearing Protection Required” notice too far from the high-noise zone it applies to? Audits reveal these oversights, giving teams the opportunity to realign signage before winter operations and annual inspections.

Using a Safety Signage Audit Checklist for Consistency

A thorough audit requires more than a quick walk-through. To achieve consistent results, facilities need a structured approach that highlights problem areas, documents deficiencies, and prioritizes corrective actions. Safety managers can make their end-of-year signage audit both effective and repeatable by following a clear framework:

- Map Critical Signage Zones: Identify high-risk areas such as chemical storage, machinery, electrical panels, and exits.

- Inspect Each Sign for Condition: Look for faded graphics, peeling edges, or cracks.

- Verify Regulatory Alignment: Compare against OSHA signage requirements, ANSI Z535, and GHS standards.

- Document Findings: Use a safety signage audit checklist with photos and notes for accountability.

- Prioritize Replacing Safety Signs: Correct high-risk items immediately and schedule updates for secondary issues.

A safety signage audit checklist helps standardize this process and ensures nothing is overlooked before the year closes.

Why End-of-Year Is the Right Time for Replacing OSHA Signs

End-of-year signage audits are the ideal time to replace safety signs because facilities are preparing for winter conditions, reviewing budgets, and scheduling inspections. Conducting an audit now allows safety managers to use remaining resources effectively and begin the new year with compliance already in place.

Instead of rushing to replace outdated workplace signage in January, teams can make updates ahead of time—reducing stress, avoiding downtime, and strengthening safety culture heading into the next cycle.

Examples of Compliant Safety Labels Across Different Industries

Every facility faces different risks, but the need for clear and compliant signage is universal. An end-of-year signage audit brings these issues to light, showing how conditions and environments can wear down even the most carefully placed signs.

The benefits of these audits show up across industries:

- Manufacturing: A “Pinch Point—Keep Hands Clear” warning near a robotic press has faded, requiring immediate replacement.

- Construction: A jobsite banner reading “Hard Hat Required Beyond This Point” has been shredded by wind, leaving new crews without guidance.

- Utilities: An electrical panel label is missing updated arc flash details, violating OSHA requirements and exposing workers to risk.

- Healthcare: A biohazard waste label has degraded after repeated sanitation, showing why compliant, chemical-resistant stock is essential.

Tools That Support Durable Workplace Signage Updates

Once an end-of-year signage audit identifies problem areas, facilities need quick and reliable ways to implement updates. In-house printing tools make this much easier. LabelForge® PRO Design Software provides prebuilt templates for compliant safety labels aligned with OSHA, ANSI, and NFPA requirements. This allows safety teams to design and print replacements on demand, rather than wait on vendors.

One of the most versatile options is the DuraLabel® Toro® Max Industrial Sign and Label System. This all-in-one printer combines portability with the power of thermal transfer printing, making it simple to update signage wherever it’s needed.

The Toro Max’s touchscreen interface and broad supply range enable teams to create compliant safety labels and durable workplace signage that meet OSHA signage requirements. During an end-of-year signage audit, it allows managers to print replacements on demand so facilities start the new year fully prepared.

When paired with DuraLabel’s supplies—chemical-resistant vinyl, reflective stock, and high-tack adhesives—facilities can produce durable workplace signage that withstands UV, moisture, and abrasion. This reduces replacement cycles, simplifies replacing safety signs, streamlines updates, and keeps workplace signage compliance on track into the new year.

Building Accountability Through Workplace Signage Compliance

An end-of-year signage audit is a facility’s commitment to worker safety. Updated signage reassures employees that their well-being is prioritized. Using a safety signage audit checklist also trains staff to recognize worn or damaged signage and take ownership of reporting issues.

For diverse teams, compliant safety labels and bilingual signs reinforce communication, reduce confusion, and protect employees across every shift.

DuraLabel Products and Resources to Help Pass Inspections

An end-of-year signage audit is the most practical way to confirm that facility visuals are clear, compliant, and ready for the challenges ahead. Addressing issues such as faded safety signs or outdated workplace signage now prevents compliance headaches later and sets the stage for a safer, more efficient new year.

The DuraLabel Toro Max Industrial Sign and Label System gives facilities the ability to print durable workplace signage and compliant safety labels on demand. Its rugged design and intuitive interface make it a reliable solution for creating OSHA- and ANSI-compliant visuals before year-end inspections.

For practical guidance on conducting an end-of-year signage audit, download the free Facility Signage Handbook. This resource covers OSHA signage requirements, ANSI formatting, and strategies for replacing safety signs before they fail.

If you have questions about your facility’s signage program, call 1-888-965-3359 to connect with a DuraLabel expert who can recommend tailored solutions for your environment.

Read Next:

OSHA Signs Regulations and Compliance: Everything You Need to Know

Why Wait? Learn How to Create Safety Signs In-House with DuraLabel

Related Resources

How Custom Signs Support OSHA Rules and ANSI Signage Requirements

Why Do Facilities Need Custom Signs to Meet OSHA Rules and ANSI Signage Requirements? Custom signage plays a ...

Read

Custom Signage Built Around OSHA ANSI Signs for Safer Workplaces

How Do Slippery When Wet Signs Prevent Common Workplace Injuries? Slippery When Wet signs prevent common ...

Read

How to Make Custom OSHA Safety Signs That Meet Compliance and Last

How Do CustomSafety Signs Help Prevent Accidents and Downtime? Custom OSHA safety signs help prevent ...

Read.png)