Water Treatment Facility Pipe Marker Benefits

Pipe marker systems are an essential part of any water treatment facility. Effective pipe marker usage improves safety and increases efficiency by providing essential information-where and when it's needed.

The Pipe Marker Standards

While there is no single standard that governs all pipe marking labels for water treatment facilities across the U.S., there are two pipe marker standards specifically developed for water treatment facilities that are in common use:

- Recommended Standards for Water Works (2022 edition)

- Recommended Standards for Wastewater Facilities (2014 edition)

Both of these are part of the 10 States Standards, developed by a coalition of ten U.S. states and one Canadian province-Illinois, Indiana, Iowa, Michigan, Minnesota, Missouri, New York, Ohio, Pennsylvania, Wisconsin, and Ontario.

Although these pipe label standards originally applied only to the ten states, other states have used them as a baseline for their own standards. This is because the 10 States Standards provide a wealth of reliable information that can improve safety and operations for public water works, including how to properly mark all kinds of pipes, from a sprinkle pipe to a complex chilled water pipe system.

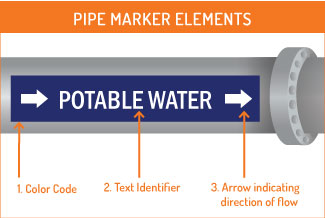

Elements of a Pipe Marker

In general, there are five elements that make an effective pipe label. These elements are used by most pipe marker standards and include:

- Color coding provides a means for workers to quickly identify the general contents of pipes as well as potential hazards.

- Text identifies the pipe's exact contents and may also display other hazards like temperature or pressure. For instance, a pipe labeled as a chilled water pipe helps to quickly identify and manage temperature-specific systems.

- Arrows indicate the direction of flow, including when contents may flow in either direction.

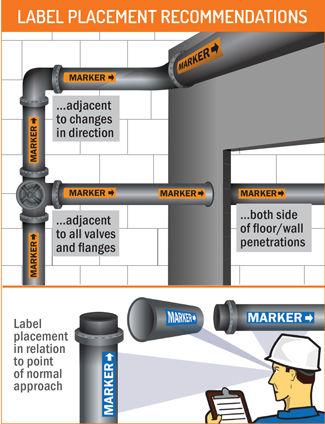

- Label placement recommendations ensure people will see the pipe label and be able to access the information they need with minimum effort.

- Size guidelines help you choose the right size pipe marker label and text to ensure pipe markers can be read.

The first four elements are specifically addressed in the 10 State Standards, while guidance for the fifth can be found in another standard: ANSI/ASME A13.1. These standards provide comprehensive guidelines ensuring clarity and uniformity in pipe marking across various industries, including water treatment facilities. Adhering to these standards not only enhances safety protocols but also facilitates effective communication and regulatory compliance within the facility.

Improve Safety with Pipe Marker Application

Water treatment facilities are complex and can contain numerous hazards, such as chemical storage areas, high-pressure systems, and intricate piping networks carrying various liquids and gases. Improperly labeled chemicals pose significant risks, potentially leading to chemical spills, exposure hazards to workers, and environmental contamination. Clear and accurate pipe marker usage not only helps mitigate these dangers but also ensures emergency responders can quickly identify and address any incidents, safeguarding both personnel and the surrounding environment.

Pipe marker solutions provides an effective means for workers to consistently identify hazards by:

- Providing information in an easy-to-read and consistent manner

- Using color-coding to support quick identification of contents

- Complimenting your chemical hazard communication program (HazCom 2012)

Supported by a comprehensive pipe color code system, workers will recognize pipes, their contents, and potential hazards from a distance, enabling them to more easily prepare for work. For example, in a wastewater treatment facility, a dark green pipe marker lets workers know that it contains pressurized air. As a result, workers are instantly aware of the hazard and know that they need to isolate and bleed the pipes before performing work.

Another added benefit of using a standardized pipe marker scheme is that it helps you meet HazCom 2012's requirements, which requires an in-depth program for communicating chemical hazards in the workplace. By taking advantage of a relevant standard, like the 10 State Standards, you can ensure that your facility consistently communicates the hazards related to the contents of its pipes.

Pipe Marker Usage to Increase Efficiency

Water treatment facilities can have many miles of piping, with varying contents. For example, it can be expected to find a chilled water pipe system for cooling facility processes and equipment, while fire sprinkler systems are a standard safety feature to protect against fire hazards. Workers have to perform routine maintenance to keep the facility in peak condition. Properly marked pipes aid workers in this task, ensuring that they can:

- Move from one task to the next without having to reference charts or binders

- Spend less time reviewing schematics because much of information they need is on the pipes

Located at the point of use, pipe marking labels help reduce errors and mistakes caused by information gaps. Workers always know what's in the pipes. Even when workers go from one facility to the next, they can confidently and efficiently perform work in unfamiliar environments.

Pipe Marker Solutions

Start marking your facility's pipes with DuraLabel line of DuraLabel printers and pipe marker supplies. Printers such as the DuraLabel Toro Max enable you to print durable labels onsite and on the go with an optional lithium-ion battery. These pipe marking labels are known for their reliability, ensuring clear identification that withstands environmental factors and maintains readability over time, enhancing overall safety and compliance efforts.

Each DuraLabel printer lets you:

- Design pipe marking labels with just a few clicks using DuraSuite labeling software

- Add supporting graphics like hazard pictograms and arrows to meet your facility's needs

- Create pipe marker solutions that will last for many years

Do more than create pipe markers. With a DuraLabel printer, you can create custom safety signs and labels for your entire facility with a database of over 1,800 symbols. Improve safety throughout your facility and meet OSHA's requirements for safety signs.

If you only need a handful of pipe markers for a specific project, visit our full selection of premade pipe markers.

To help you get started, we are offering a free Pipe Marking Instant Action Guide to keep handy when creating pipe labels in your facility. Download below for step-by-step labeling instructions, a pipe marking color guide, a facility inspection worksheet, and more!

Read Next:

Pipe Marking & Pipe Corrosion Control

Pulling Back the Curtain: A Look at DuraLabel’s Tough-Tested Process

Related Resources

The Benefits of Pipe Marking

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe ...

Read.png)

Navigating Pipeline Pathways with Directional Pipe Markers

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These ...

Read

Pipe Makers & Pipe Labels | Piple Marking Labels

Workplaces are safer than ever, but challenges remain: In 2014, nearly three million nonfatal workplace ...

Read.png)