How Emergency Preparedness Protects Utilities and Energy Operations

Why Is Emergency Preparedness Critical in Utilities and Energy?

U.S. businesses and households lose nearly $79 billion each year from power interruptions. For energy providers, even short outages create cascading risks that impact operations, safety, and the bottom line—making utility emergency preparedness essential.

Clear safety visuals—labels, signs, and markers—must remain legible when it matters most. Durable utility safety labeling provides clarity, guiding crews through hazards, shutdowns, and crisis scenarios where every second counts.

Why Preparedness Defines the Utilities Sector

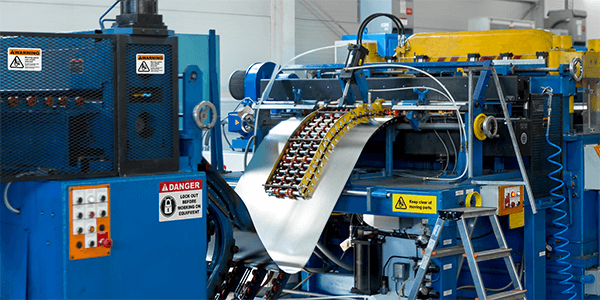

From wildfires and hurricanes to blackouts and chemical leaks, the utilities and energy sector faces constant threats. Employees work around high-voltage systems and fuel lines while maintaining heavy equipment that can become dangerous in an instant.

Readiness is measured by how quickly teams can act when incidents occur. Standards from OSHA, NFPA, and ANSI outline requirements for electrical safety labeling, pipe markers, and signage that communicate critical details. When utility safety labeling holds up under stress, operations stay organized, downtime is reduced, and crews remain protected—reinforcing the role of emergency preparedness across the sector.

The Cost of Poor Emergency Preparedness

The financial and human costs of inadequate planning are significant. OSHA fines add to the pressure: a single serious violation, such as a missing or illegible safety label, can cost up to $16,550 per incident.

Picture a substation damaged during a storm. If circuit disconnects are not clearly marked with OSHA compliance labeling, technicians lose valuable minutes tracing power sources before they can safely restore service. Every delay extends outages, drives up costs, and increases risk to the crew in the field. Reliable electrical panel labels and utility safety labeling save hours during recovery and give workers immediate clarity when they need it most.

Clear Messaging as the Backbone of Response

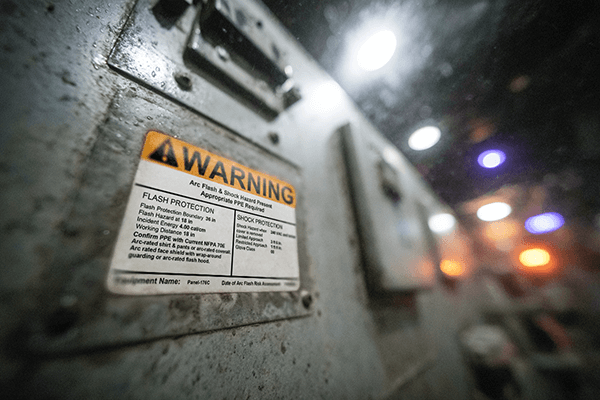

Emergencies unfold quickly, and hesitation can make the situation worse. Safety labels and signage provide utility workers with direct, reliable information they can act on immediately. Arc flash labels, for example, specify required PPE levels and incident energy values that help electricians make safe decisions under pressure.

In practice, visual systems in utility operations should cover:

- Hazards: Energized equipment, combustible gases, pressurized steam, or chemical exposure.

- Evacuation Routes: Direct employees to assembly points during outages, fires, or spills.

- Critical Shut-Off Points: Power, gas, or water that must be accessed quickly.

- Restricted Zones: Areas where only trained personnel may enter.

- Emergency Equipment Locations: Spill kits, eyewash stations, or extinguishers.

Consider a technician entering a control room during a storm-related outage. Without clear electrical safety labeling on panels, they risk accidental exposure to live circuits. A reflective label reading “480V—Arc Flash Hazard—PPE Level 2 Required” provides instant instruction, giving crews the confidence to act decisively and safely under pressure—illustrating another critical component of emergency preparedness.

Real-World Events That Highlight Emergency Preparedness

Storm-driven outages, wildfires, and substation failures continue to expose vulnerabilities in utility infrastructure. In 2023, the U.S. Bureau of Labor Statistics (BLS) recorded 5,283 workplace fatalities, with electrical exposures a significant contributor.

Organizations that rely on generic or degraded signs often lose time during recovery. Workers may spend crucial minutes searching for shut-offs or misinterpreting faded instructions.

By contrast, companies that invest in reflective, chemical-resistant, and glow-in-the-dark visuals maintain clarity even in extreme conditions. A photoluminescent sign in a darkened control room points the way to an exit. A reflective pipe marker helps a technician quickly identify the line that must be shut off to contain a leak. Durable utility safety labeling removes guesswork and supports faster, safer decisions—key pillars of effective emergency preparedness.

How Utility Safety Labeling Strengthens Compliance in Utilities

Strong labeling practices directly support compliance with federal and industry standards. Utilities must adhere to several key requirements:

- OSHA 29 CFR 1910.145: Accident prevention signs and tags must be legible, visible, and resistant to wear.

- ANSI/ASME A13.1: Pipe marking requirements include color-coding and size for visibility on pressurized steam, gas, or chemical lines.

- NFPA 70E: Electrical equipment labels must communicate arc flash boundaries, incident energy, and required PPE.

Take an ammonia refrigeration system as an example. A utility crew responding to a leak depends on IIAR-compliant pipe markers that resist extreme temperatures and chemical exposure. Without durable OSHA compliance labeling, shutdowns may be delayed and the risk of escalation rises significantly. Together, these standards form the blueprint for utility safety labeling that supports safe decisions under pressure.

Materials That Withstand Utility Conditions

Utility environments are tough. Labels face heat from transformers, constant moisture from cooling systems, and abrasion from frequent handling. Standard stickers and paper signs cannot stand up to those conditions.

Industrial-grade label durability makes the difference between a safe, efficient recovery and a dangerous delay. DuraLabel’s tough-tested supplies are built specifically for these demands.

Materials especially critical for utilities include:

- Reflective Vinyl Labels: Stays visible in dark or smoky substations.

- High-Temperature Poly Tape: Resists cracking near boilers, motors, and transformers.

- Photoluminescent Signage: Glows in the dark when power fails.

- Chemical-Resistant Label Stock: Stands up to oils, solvents, and cleaners.

- Heavy-Duty Adhesive Vinyl: Bonds securely to textured or uneven outdoor surfaces.

Think of a substation exposed to both extreme summer heat and heavy winter storms. High-temp labels keep equipment legible while reflective vinyl improves visibility during low-light maintenance. Investing in industrial-strength labeling durability reduces relabeling costs and keeps emergency systems ready for the next incident—further supporting strong emergency preparedness programs.

Building a Culture of Emergency Preparedness

Emergency planning works best when it becomes part of the culture. Utilities that treat readiness as an ongoing practice reinforce safety, strengthen compliance, and protect trust in critical services.

A strong program includes:

- Regular Audits of Signs and Labels: Identify and replace missing, damaged, or outdated visuals.

- Training on Hazard Recognition and Incident Response: Ensure employees know how to act on the information labels communicate.

- In-House Labeling Systems: Tools like a DuraLabel Industrial Sign and Label System allow teams to print updates immediately when hazards or layouts change.

- Bilingual or Pictogram-Based Signage: Reach diverse workforces and eliminate confusion.

- Close Tracking of OSHA, NFPA, and ANSI Updates: Reduce compliance risks and avoid costly citations.

Utilities that maintain these practices strengthen emergency preparedness, reduce downtime, and protect public confidence.

Streamlining Labeling with DuraLabel LabelForge PRO Design Software

Emergency preparedness depends on speed, and the right software can make all the difference. DuraLabel LabelForge PRO Design Software gives utilities an intuitive way to create compliant labels and safety signs on demand. With built-in templates for arc flash, OSHA, ANSI, and GHS standards, crews never need to start from scratch. This saves time during audits, simplifies updates when regulations change, and helps ensure accuracy across every facility.

DuraLabel Products and Resources for Utility Preparedness

Utility operations are a cornerstone of critical infrastructure, and downtime is costly. Crews need tools that deliver clear, reliable labeling under pressure. The DuraLabel Toro Max Industrial Sign and Label System provides that capability. Its portable, all-in-one design lets teams print arc flash labels, evacuation signs, and pipe markers directly on-site—saving time during outages and keeping hazards visible in changing conditions.

For added support, DuraLabel offers the free Industrial Data Center Labeling Quick Start Guide. While originally created for data centers, the guide includes strategies utilities can apply to power generation and distribution. It covers OSHA, NFPA, and ANSI compliance along with best practices for labeling critical systems. It is a practical resource for boosting resilience and reducing downtime.

Need tailored guidance? Call 1-888-786-9223 to connect with a DuraLabel representative who can recommend the right products, supplies, and approaches for your utility.

Read Next:

Pipe Marking Basics: OSHA and ANSI/ASME Labeling Standards

The Case for Custom Workplace Signs in Complex Environments

Related Resources

Why Custom Industrial Labels Matter for Mechanical Job Sites

How Do Custom Industrial Labels Improve Safety and Organization on Job Sites? Mechanical job sites are ...

Read

Industrial Labeling Trends Driving Facility Compliance Forward

How Are IndustrialLabeling Trends Shaping Safety and Compliance? Industriallabeling trendsare shifting ...

Read

Learn How to Create Custom Safety Signs In-House with DuraLabel

Why Should Facilities Create Custom Safety Signs In-House? Creating clear, compliant signage is a constant ...

Read.png)