A Comprehensive Guide to Choosing the Right Industrial Label Printer

What is an Industrial Label Printer?

An industrial label printer is a thermal transfer or direct thermal printer designed to create durable safety labels, signs, and inventory markers. These printers support everything from asset tags and barcodes to large format labels and safety identification. As workplaces evolve and regulations tighten, selecting the right industrial label printer, like the DuraLabel® Kodiak® Max Industrial Sign and Label System, becomes paramount. Let’s explore the world of industrial labeling, look at its applications across industries, and offer guidance on choosing the perfect printer to safeguard your workforce and streamline operations.

The sections below explain the main printer types, differences between thermal printer vs inkjet technologies, and how to choose the right industrial label printer for workplace needs:

-

The key features of industrial label printers

-

Comparing thermal transfer and inkjet label technologies

-

What to consider for large format and 5S visual systems

-

How printer choice affects label durability and compliance

Next, we’ll break down the essential features that make a printer suited for industrial use and heavy workloads.

What Are Industrial Safety Labels?

Industrial safety labels are durable signs and markings designed to withstand harsh environments while communicating hazards, equipment instructions, and safety protocols. They support compliance with OSHA and ANSI standards and help protect workers by making critical information visible at the point of use.

In a visual workplace, clear communication is essential. Industrial safety labels organize inventory, mark hazards, and reinforce safe operating procedures across facilities. To produce these labels reliably, organizations rely on industrial label printers built for demanding conditions.

Clear and concise communication is essential to ensure the safety of all personnel in a visual factory. Industrial label printers, including thermal transfer printers and direct thermal models, allow facilities to create labels and signs that communicate hazard warnings, safety instructions, equipment identification, and emergency procedures. Whether it's identifying potential hazards or providing instructions for safe operation, these safety labels play a pivotal role in keeping workers informed and aware of their surroundings.

Efficient inventory management is vital for the smooth operation of any industrial facility. A thermal transfer printer allows organizations to categorize, track, and identify inventory items with ease. Whether it's labeling storage bins, shelves, or individual products, these printers help:

- Streamline inventory processes

- Reduce errors

- Improve overall efficiency

Organizations can minimize the risk of inventory mix-ups and improve workflow productivity when items are properly labeled and easily identifiable.

Industrial label printers play a crucial role in helping organizations maintain compliance with various safety regulations, including those set forth by organizations such as Occupational Safety and Health Administration (OSHA) and American National Standards Institute(ANSI). These printers help ensure that workplaces are safe and compliant with applicable laws and regulations by producing clear and visible warning labels that adhere to regulatory requirements.

In addition to promoting safety, thermal label printers also contribute to overall workplace efficiency. By providing organizations with the ability to create custom labels and signs on-demand, these printers eliminate:

- The need for manual labeling processes

- Reduce downtime

- Improve operational efficiency

Whether it's labeling equipment, marking aisles, or creating signage for facility navigation, these printers help organizations streamline processes and improve productivity.

How Are Industrial Label Printers Used Across Different Industries?

Industrial label printers are used across manufacturing, construction, healthcare, warehousing, and food processing to create compliant safety signs, wayfinding markers, and hazard communication labels. Their versatility makes them essential for nearly every industrial environment.

How Are Industrial Label Printers Used Across Different Industries?

Industrial label printers are used across manufacturing, construction, healthcare, warehousing, and food processing to create compliant safety signs, wayfinding markers, and hazard communication labels. Their versatility makes them essential for nearly every industrial environment.

From production floors to medical facilities, thermal transfer printers support visual communication by producing labels that hold up to chemicals, abrasion, moisture, and temperature changes. These labels help organizations standardize safety messaging, identify hazards, mark equipment, and reinforce procedures across departments and job roles.

Regardless of industry, effective visual communication is a core part of a strong safety program. Industrial label printers allow teams to create and update labels on demand, keeping information accurate as processes, materials, and risks change.

Manufacturing Safety and Compliance with Industrial Label Printers

Label printers serve as guardians of safety, producing labels and signs that identify machinery, warn of potential hazards, and provide crucial instructions for safe operation. By ensuring clear and visible communication, these printers help mitigate risks, prevent accidents, and maintain compliance with regulatory standards such as those set forth by OSHA and ANSI.

Using a thermal transfer printer allows manufacturers to produce durable labels that withstand oils, chemicals, abrasion, and temperature changes commonly found on production floors. This durability ensures safety information remains visible throughout the life of equipment and processes.

Warehousing and Logistics Labeling for Inventory Efficiency

In warehousing and logistics, accurate labeling is essential for efficient inventory management. Industrial label printers are used to create clear labels for storage bins, shelving, pallets, and individual products, helping teams track and identify materials quickly.

A thermal transfer printer supports this process by producing labels that remain readable in high-traffic areas and variable environmental conditions. Proper labeling helps:

-

Reduce picking and stocking errors

-

Improve workflow efficiency

-

Minimize inventory mix-ups

When inventory is clearly labeled and easy to identify, operations move faster and with fewer disruptions.

Construction Site Safety with Thermal Transfer Label Printers

Construction sites change constantly, which makes clear visual communication essential. Industrial label printers, especially a thermal transfer printer, are used on jobsites to create durable safety signage that marks hazardous areas, outlines safe work practices, and supports OSHA compliance.

Labels and signs produced with thermal transfer printing hold up to dust, weather, and heavy handling, ensuring warnings remain visible as conditions shift. By clearly identifying risks and expectations, labeling helps reduce accidents and keeps workers informed in fast-moving construction environments.

Healthcare Safety and Compliance Using Industrial Label Printers

In healthcare settings, clear labeling directly supports patient safety and regulatory compliance. Thermal transfer printers are used to produce durable labels for medical equipment, medication, and patient records.

These printers play a critical role in promoting patient safety and regulatory compliance that range from identifying equipment to ensuring proper medication management. Sign printers help healthcare organizations maintain high standards of safety and quality of care by producing clear and legible labels that withstand the rigors of healthcare environments.

Food Processing Safety and Compliance with Thermal Transfer Printers

Food processing facilities operate under strict regulations to ensure food safety and hygiene. Industrial label printers, such as the DuraLabel Kodiak Max, offer specialized labeling solutions designed to withstand wash-downs, resist contamination, and comply with regulatory requirements.

From labeling food products to marking processing equipment, these printers help maintain hygiene standards and ensure compliance with regulations set forth by organizations such as the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA).

Wayfinding Labels for Clear Facility Communication

Any type of facility can benefit from effective wayfinding. Signs, lines, and labels that direct workers and visitors through the facility with simple, easily accessible information. This extends to emergency exit procedures, hazard zones, and vehicle traffic areas. Glow-in-the-dark signs and labels are especially important for identifying evacuation routes and exits in a power outage.

Enhancing Safety Across Industries

Industrial label printers are versatile tools used across industries to address a wide range of safety challenges. From manufacturing and construction to healthcare and food processing, these printers support safety, efficiency, and regulatory compliance.

By enabling organizations to create clear, durable, OSHA-compliant labels and signs on demand, industrial label printers help maintain safer, more organized workplaces across diverse environments.

Why Should Facilities Choose an Industrial Label Printer Over Standard Printers?

Facilities choose industrial label printers because they are built for durability, compliance, and consistent output in environments where office printers fail. Standard inkjet or desktop printers are designed for paper, not for exposure to dust, chemicals, moisture, or temperature swings.

In a thermal printer vs inkjet comparison, the difference is practical. Inkjet printers rely on liquid ink that can smear, fade, or break down in industrial conditions. Industrial printers, especially thermal transfer printers, use heat and ribbon-based printing to create labels that resist abrasion, chemicals, and long-term wear.

Industrial label printers also support a wider range of materials, allowing facilities to produce labels for pipes, equipment, safety signs, and harsh-use environments while meeting OSHA and ANSI requirements. That reliability reduces rework, improves efficiency, and ensures safety information stays visible for the life of the label.

What Is the Difference Between Industrial Thermal Printers and Inkjet Printers?

The main difference is how the image is created and how long it lasts. Industrial thermal printers use heat-based technology to produce durable labels, while inkjet printers spray liquid ink onto paper, which is better suited for office or short-term use.

In a thermal printer vs inkjet comparison, thermal printers are designed for industrial labeling needs such as barcodes, safety signs, pipe markers, and equipment labels. Thermal transfer printers, in particular, use heat and ribbon combinations to create labels that resist chemicals, abrasion, moisture, and fading.

Inkjet printers can produce high-resolution images and photos, but they are limited in material compatibility and durability. Ink can smear, fade, or break down when exposed to environmental conditions common in industrial settings. As a result, inkjet printers are typically used for documents, not for long-term labeling in production, warehouse, or safety applications.

For facilities that need reliable, compliant, and long-lasting labels, industrial thermal printers are built to meet demands that standard inkjet printers cannot support.

How Do Inkjet Printers Work?

Inkjet printers create images by spraying microscopic droplets of liquid ink onto paper. These droplets blend together to form text, graphics, and photo-quality images. Print resolution is measured in dots per inch (DPI), with higher DPI producing finer detail and smoother images.

Inkjet technology is designed primarily for office and document printing, where image quality matters more than long-term durability or environmental resistance.

Advantages and Limitations of Inkjet Printers

Inkjet printers offer some clear benefits, but they also come with limitations that matter in industrial settings.

Advantages

-

Lower upfront cost compared to industrial systems

-

Capable of high-resolution, photo-quality printing

-

Suitable for documents, graphics, and short-term labels

Limitations

-

Ink-based prints are prone to smudging, fading, and moisture damage

-

Limited compatibility with durable label materials

-

More moving parts increase maintenance needs and reliability concerns

-

Not designed for harsh environments or regulatory labeling

Because of these limitations, inkjet printers are rarely suitable for safety labels, barcodes, or applications that require long-lasting, compliant identification.

What is a Thermal Label Printer?

A thermal label printer uses heat to transfer pigment from a ribbon or activate heat-sensitive material, creating durable and compliant labels. This makes them ideal for safety labeling, inventory management, and compliance-driven applications.

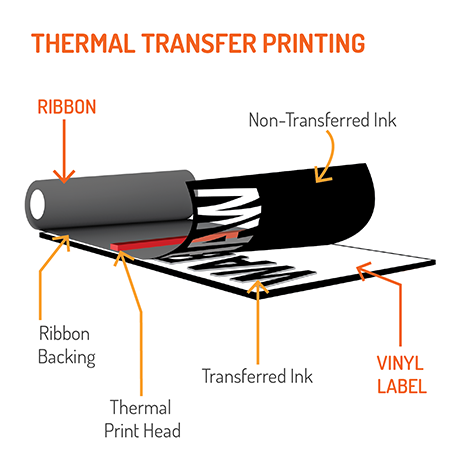

Unlike inkjet printers, thermal printers don't spray liquid ink through a nozzle to produce images. Rather, thermal printers use tiny heating elements to activate or transfer pigments.

Industrial thermal printers are used most commonly to create labels, safety signs, wayfinding markers, barcode labels, shipping labels, and other heavily used items.

How do Thermal Printers Work?

Two primary technologies dominate the industrial labeling landscape: thermal transfer and direct thermal printing.

- Thermal Transfer Printing: This technology uses a heated print head to transfer ink from a ribbon onto the label material. It offers excellent durability, making it suitable for applications requiring durable labels that can withstand harsh environments and exposure to chemicals or UV radiation.

- Direct Thermal Printing: In direct thermal printing, heat-sensitive paper is used to create images without the need for ink or ribbons. While this technology is more cost-effective and time-efficient for less demanding applications, it may not offer the same level of durability as thermal transfer printing.

Consider your specific application requirements, such as durability, print quality, and cost-effectiveness, when choosing between these technologies. Selecting the right printing technology ensures that your labels meet the demands of your application while optimizing efficiency and cost-effectiveness.

What are the Advantages of Using an Industrial Thermal Label Printer?

The main advantages of industrial thermal printers include durability, versatility, and low maintenance. They are specifically designed to produce long-lasting labels that withstand tough environments.

There are several reasons to consider an industrial thermal printer for your facility. Here are a few advantages of investing in a thermal printer:

- Durable: Labels and signs created with thermal printers are built to last. They withstand harsh environments, resist fading, and remain legible under a wide variety of weather conditions, making them far more durable than those printed with ink. This durability ensures that your labels and signs maintain their integrity and clarity over time, even in extreme conditions.

- Versatile: Thermal transfer printers excel in versatility. They can produce a diverse range of documents, labels, and signs tailored to meet various needs. Whether you need durable arc flash labels, detailed and vibrant floor markings, or labels designed to endure extreme conditions like cold storage, thermal printers deliver reliable results. This adaptability makes them ideal for a wide array of applications in different industries.

- Less maintenance: Thermal printers are engineered for longevity and reliability. With fewer moving parts compared to inkjet printers, they require less frequent maintenance and are easier to service. This translates to reduced downtime and lower overall maintenance costs, ensuring that your operations run smoothly and efficiently. Their robust design and reliable performance make thermal printers a cost-effective investment for any facility.

What are the Limitations of a Thermal Transfer Label Printer?

While industrial thermal transfer printers are known for reliability and durability, they do come with a few tradeoffs that facilities should consider when choosing a printing system.

- Upfront cost: Thermal transfer printers and ribbons typically cost more than inkjet systems, especially at purchase. Industrial-grade hardware and specialty materials raise initial investment, even at entry level.

- Color limitations: Thermal transfer printing supports fewer color options and is not intended for photo-quality images. Wax and resin ribbons limit color range compared to inkjet, particularly for complex graphics or high-resolution visuals.

Despite these minor disadvantages, DuraLabel offers a thermal transfer two-color printer in the Kodiak Max and a variety of stock with different base colors that puts these worries to rest.

When Should You Use a Thermal Printer Instead of an Inkjet Printer?

Use thermal printers when durability, compliance, and efficiency are required—such as safety labels, floor marking, and pipe identification. Inkjet printers are better suited for short-term office or photo printing.

With so many printer choices and label standards, it can be tough to know when one type of printer is better suited than the other.

Use an Inkjet Printer for:

- Office printing: Print basic office materials, like contracts, manuals, and emails.

- Photographs: Produce high-quality photographs.

- Temporary signage: Create short-term notices, announcements, and reminders designed for short-term use (such as a sign informing workers that a meeting has moved rooms).

Use a Thermal Transfer Printer for:

- Durable signs and labels: Create signs and labels that withstand extreme environments and meet OSHA and NFPA standards. This includes arc flash labels that highlight electrical hazards, marine signage designed to resist water and salt exposure, and safety signs for identifying hazards and providing instructions. These durable signs and labels ensure compliance with regulatory requirements and maintain their clarity and legibility over time, even in harsh conditions.

- Specialized visual communication: Generate custom visual communication tools tailored to your facility's unique needs. This includes magnetized shelving labels that can be easily repositioned, wire wraps that provide clear identification for cables and wires, and low-light visual aids that enhance visibility in dimly lit areas. These specialized solutions improve organization, streamline processes, and enhance safety by ensuring critical information is easily accessible.

- Floor marking: Boost efficiency and safety with custom floor marking signs. These markings can be designed to create clear pathways for foot and vehicle traffic, section off hazardous areas, and alert pedestrians to forklift traffic. With customizable options, you can design floor markings that fit your facility’s layout and safety protocols, improving overall workflow and reducing the risk of accidents.

- Pipe marking: Ensure compliance with precise pipe marking solutions that meet industry standards and regulatory requirements. These markers clearly identify the contents of pipes, flow directions, and other critical information, enhancing safety and operational efficiency. Durable and easy to read, these markings help prevent accidents and ensure that maintenance personnel have the information they need to work safely.

The versatility of thermal transfer printers in creating durable signs, specialized visual communication tools, floor markings, and precise pipe labels makes them indispensable in industrial settings. These printers excel in meeting stringent safety standards and enhancing operational efficiency across various applications.

As businesses seek to optimize their printing solutions, understanding the specific requirements and capabilities of different thermal printers is crucial. From selecting the right printer technology to evaluating features that align with your facility’s needs, navigating these choices ensures you find the perfect industrial label printer that enhances safety, compliance, and productivity.

How Do You Choose the Perfect Industrial Label Printer?

Choosing the right industrial label printer depends on how much you print, where the printer will be used, and what long-term costs look like. Evaluating these factors up front helps facilities select a system that supports daily operations without creating avoidable downtime or rework.

Volume Needs: Matching Capacity to Demand

Start by assessing how many labels you need to print on a typical day. Some facilities produce a handful of labels at a time, while others run continuous, high-volume jobs. Select a printer that can handle your volume requirements without compromising on quality or efficiency.

DuraLabel Kodiak Max is a one-stop print shop, Toro Max is fully portable, and Bronco Max is an efficient, dependable workhorse. Whether it's high-volume production or occasional labeling tasks, matching the printer's capacity to your demand is essential for seamless operations.

Environmental Conditions: Adapting to the Work Environment

The working environment plays a significant role in determining the suitability of a sign printer. Consider factors such as temperature variations, humidity levels, exposure to chemicals, and UV radiation. Choose a printer that can withstand these harsh conditions, and print chemical resistant labels, without compromising performance or durability. Whether it's a dusty warehouse or a chemical-laden manufacturing plant, selecting a printer that is built to thrive in your specific environment is crucial for long-term reliability.

Cost Analysis: Beyond the Price Tag

While upfront cost is an important consideration, it's essential to look beyond the price tag and evaluate the total cost of ownership. Consider ongoing expenses such as consumables (e.g., labels and ribbons) and maintenance costs. Conduct a thorough cost analysis to ensure that the chosen industrial color label printer aligns with your budgetary constraints over the long term. Sometimes, investing a little more in a higher-quality printer like the Kodiak Max can result in significant cost savings down the line.

How Do Industrial Label Printers Improve Safety and Compliance?

Industrial label printers improve safety by creating clear, compliant warning labels and improve compliance by meeting OSHA, ANSI, and NFPA requirements. Compliance with regulatory standards stands as the cornerstone of a secure and healthy work environment. Industrial color label printers are indispensable allies in this endeavor, enabling organizations to meet regulatory requirements while mitigating safety risks. As part of your safety program, printers ensure compliance and enhance safety in the workplace.

Clear and Visible Safety Labels

Sign printers are instrumental in producing custom safety labels that are clear, legible, and prominently displayed throughout the workplace. These labels play a critical role in providing vital information to workers, particularly in emergencies. Whether it's warning of potential hazards, providing instructions for safe operations, or identifying emergency exits, these safety labels serve as visual cues that guide workers and help prevent accidents.

By utilizing label printers to create clear and visible labels, organizations enhance communication and promote a culture of safety in the workplace. These labels serve as constant reminders of safety protocols and emergency procedures, empowering workers to make informed decisions and respond effectively to potential risks.

Navigating Safety Standards

In today's regulatory landscape, compliance with safety standards is non-negotiable. Industrial label printers play a crucial role in ensuring that organizations meet regulatory requirements set forth by organizations like OSHA and ANSI.

By producing labels that comply with regulatory standards, label and sign printers help organizations navigate the complex web of safety regulations with confidence. From the design and layout of warning labels to the selection of materials and adhesives, these printers ensure that labels meet stringent requirements and withstand regulatory scrutiny.

Empowering Organizations to Prioritize Safety

Industrial label printers empower organizations to prioritize safety and invest in proactive measures to mitigate risks. By providing the tools to create labels tailored to specific workplace hazards, these printers enable organizations to address safety concerns proactively and implement targeted safety solutions.

Moreover, these printers facilitate regular inspections and maintenance by producing labels that identify equipment, indicate inspection dates, and provide maintenance instructions. Organizations reduce the risk of accidents and promote a safe working environment for all personnel by ensuring that equipment is properly labeled and maintained.

Enhancing Safety Through Compliance

The thermal transfer label printer is an indispensable tool for ensuring compliance with regulatory standards and enhancing safety in the workplace. These printers play a pivotal role in promoting a culture of safety and mitigating risks by producing clear and visible labels and helping organizations navigate safety standards. As organizations continue to prioritize safety in the workplace, label printers will remain essential allies in safeguarding the well-being of workers and fostering a secure and healthy work environment.

Why Choose DuraLabel?

DuraLabel printers are designed for industrial safety and compliance, offering durability, software tools, and versatility across applications. Selecting the right printer is a critical decision that impacts both safety and efficiency in the workplace. By understanding diverse labeling solutions across industries, evaluating key considerations in printer selection, and staying abreast of emerging trends, organizations can ensure the safety and well-being of their workforce while optimizing operational performance. Label printers aren't just machines; they're guardians of safety and productivity in the modern industrial landscape.

Whether you need safety signs, pipe markers, or equipment labels—Toro Max and Kodiak Max are ready to transport anywhere you are. Get help crafting a system that will provide the safety communication you need. Call 1-888-965-3359 and one of our experts will guide you through the process.

For any application: safety, 5S, lean manufacturing, pipe marking, equipment labels, overhead signs, wayfinding, racks, shelves, bins, bilingual signs, and more, DuraLabel printers, with the powerful LabelForge Pro software, can provide instant visual communication.

Learn more about how to stay up to speed on signs and labels that can be used to help create a safer environment that leaves workers at ease knowing management cares. Download our free Facility Safety Handbook today.

Read Next:

Related Resources

Top 10 Uses for DuraLabel Industrial Label Printers

How DuraLabel Printers are Used Across 10 Key Industrial Applications DuraLabel printers are built to solve ...

Read

Safety Signs Best Practices for Safer, More Compliant Workplaces

How Does Proper Safety Signage Improve Compliance and Reduce Workplace Risks? Proper safety signs play a ...

Read

Find the Right Field Printer for On-Site Safety and Compliance

Why Do You Need a Field Printer for On-Site Projects? A field printer is essential because it allows crews to ...

Read.png)

-png.png?width=1140&height=300&name=DuraLabel-OSHA_Pillar-Banner%20(1)-png.png)