Navigating Pipeline Pathways with Directional Pipe Markers

11

April,

2024

5 MINUTE READ

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These markers are vital communicators that safely guide workers through a maze of pipelines.

But how do workers understand these markers and apply them correctly? And how can you ensure these markers meet the standards set forth by the American National Standards Institute (ANSI)?

Join us as we explore the purpose, analyzation, and application process of directional pipe markers.

Understanding the Purpose of Directional Pipe Markers

Before we talk about how workers use directional pipe markers, it's key to know why they are important. Directional pipe markers show which way things are moving in the pipes and what's inside them. The benefits of pipe markers include workers using them to find their way around and avoid accidents.

Interpreting the Language of Directional Pipe Markers

Directional pipe markers show:

- Colors

- Shapes

- Symbols

The markers communicate critical information immediately. Understanding these visuals is crucial for workers asked to apply these markers. Let's break down the key elements:

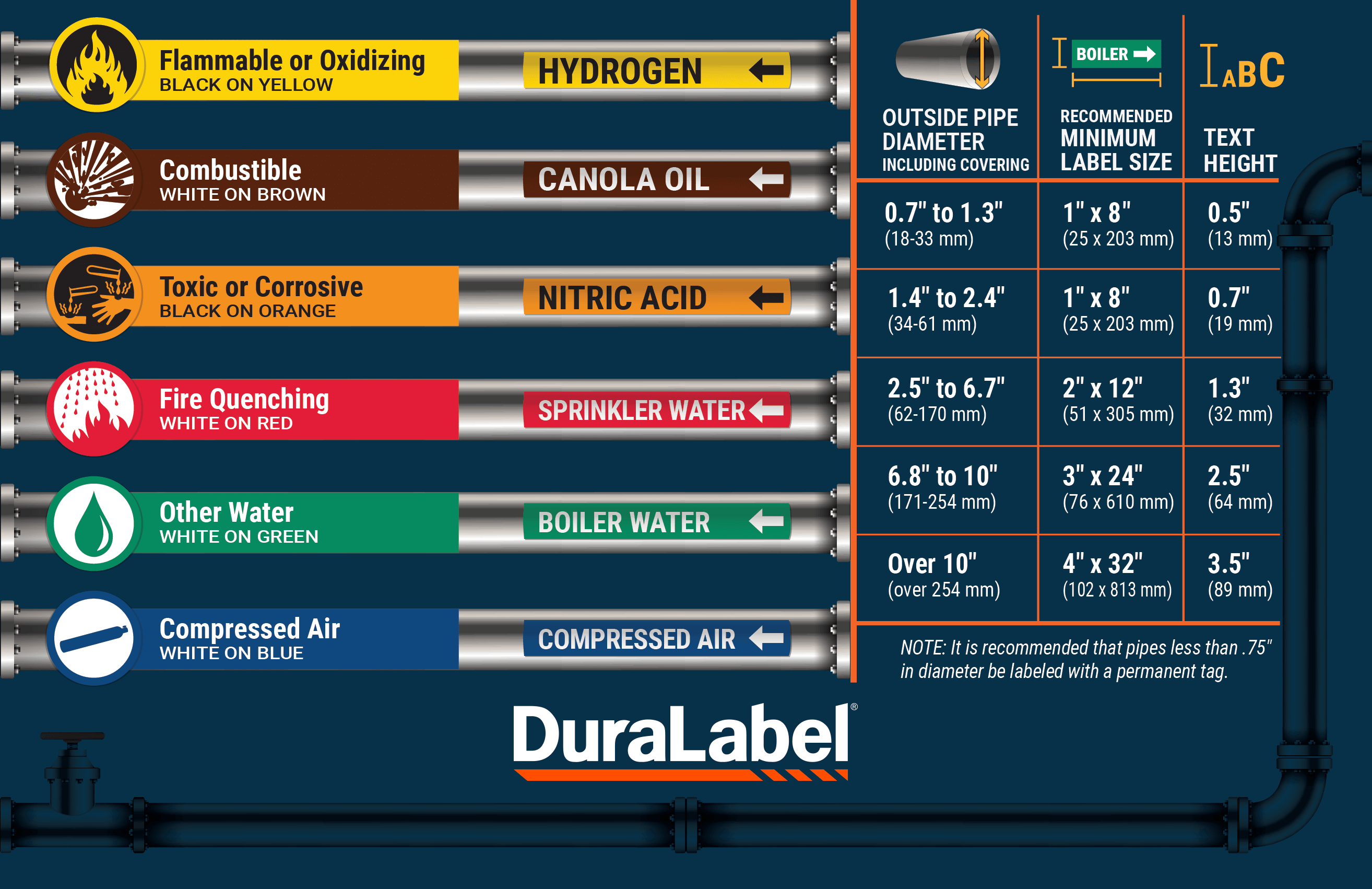

Color Coding

Different colors represent various types of substances or contents flowing through the pipeline. For instance, yellow denotes flammable materials, while green signifies non-potable water. Workers need to understand these color codes so they can identify what is moving through the pipes and take the right precautions.

Arrow Direction

Arrows on directional pipe markers show the direction of flow within the pipeline. Whether it's fluid moving horizontally, vertically, or in many directions, these arrows provide clear guidance for workers. This ensures they follow the correct path and avoid potential setbacks.

Text and Symbols

Alongside colors and arrows, directional pipe markers often feature text and symbols that provide additional information. This could include details such as the contents' temperature, pressure, or specific hazards associated with the pipeline. Interpreting these elements is vital for workers to make decisions and follow safety protocols.

Are My Pipe Markers Compliant with the ANSI/ASME A13.1 Standard?

Making OSHA-compliant pipe markers is a critical element for creating a safe job site. The best way to know if your signs meet those requirements is by following the ANSI/ASME A13.1 standard.

Workers must follow industry standards and regulations for installing directional pipe markers, including the ANSI guidelines, especially the ASME A13.1 standard. ASME A13.1 provides instructions for the size, color coding, and placement of pipe markers. This allows consistency and clarity in sharing information about the contents and flow direction of pipelines.

The ASME A13.1 standard sets up color-coded systems for various substances. For example, it shows:

- Yellow is for flammable fluids

- Green is for non-drinkable water

- Red is for fire-fighting substances

This standard also states the use of directional arrows to show the flow direction within the pipes. This allows workers to quickly interpret the information provided by the markers.

Workers who follow ASME A13.1, and other important standards, help keep pipeline systems consistent and organized. Creating markers that look and go the same way not only makes things safer by reducing confusion, but also helps workers discover what is in the pipes faster and more accurately.

Obeying standards like ASME A13.1 shows a dedication to following rules and doing things safely in industries. It helps companies:

- Lower the chances of problems with pipelines

- Keep workers safe from dangers

- Reduce the chances of accidents

By incorporating ANSI and ASME guidelines into their practices, workers allow directional pipe markers to do their job well. These standards are crucial for keeping workplaces safe, efficient, and compliant.

Steps for Applying Directional Pipe Markers

Now that we've explained why directional pipe markers are key and how to make sure they meet labeling rules, let's see the right way to put up a directional pipe marker:

-

Preparation and Planning

Before any installation, gather all the tools and materials needed, including directional pipe markers, attachment equipment (such as pipe grabber sleeves or cable ties), and cleaning supplies.

Look at the pipeline layout and find spots where you need directional pipe markers. Remember any turns, places where pipes meet, or where you can get to the pipes. -

Surface Preparation

Make sure the pipeline surface is clean, dry, and clear of any dirt, debris, or grease that might stop the pipe marker from sticking.

Clean the area where you'll put the directional pipe marker using supplies like isopropyl alcohol or mild soap. Let the surface dry before you move on.

-

Selecting the Correct Pipe Marker

Refer to the standards and rules, like ANSI/ASME A13.1, to decide on the color coding and labeling requirements for what's in the pipeline.

Pick directional pipe markers that follow these rules and work well for what you need, thinking about things like the size of the marker and how durable they are.

-

Positioning and Alignment

Carefully position the directional pipe marker at the right location on the pipeline, ensuring that it is pointing the same way as what is flowing inside the pipe.

Use measuring tools, such as a tape measure or level, to check the alignment and placement of the pipe marker. This is especially important if multiple markers need to be installed along a straight section of pipe. -

Securing the Pipe Marker

There are countless methods to properly secure your pipe marker. For example, you can take advantage of DuraLabel’s Coiled Pipe Markers to snap markers into place. You may also prefer DuraLabel’s easy-to-apply, pressure-sensitive adhesive pipe markers that let you place the marker directly onto the pipe.

No matter how the markers are locked in place, it’s critical they are done effectively to ensure they will not become easily moved.

-

Final Inspection and Testing

Once the directional pipe marker is placed, inspect it to verify that it is securely attached and positioned correctly.

Test the visibility and legibility of the pipe marker from different angles and distances. Confirm that it can be easily read and understood by workers in the area.

Make any adjustments to the installation as needed to ensure compliance with standards.

-

Documentation and Maintenance

Keep detailed records of the installation, including the locations and details of each directional pipe marker.

Have a regular inspection and maintenance schedule to monitor the condition of the pipe markers.

While looking over each pipe, check that they remain:

-

- Visible

- Legible

- Securely attached

Workers can effectively put in directional pipe markers to improve safety, navigation, and follow the rules in industrial pipelines by carefully following these steps and implementing best practices.

Training and Education

Lastly, it's crucial your workers have the knowledge and skills needed to understand and apply directional pipe markers. Employers should provide in-depth training programs covering topics such as:

- Understanding color coding protocols

- Interpreting directional signs

- Familiarizing with common symbols and written information

- Practicing proper installation techniques

- Reinforcing safety protocols and regulatory compliance

The Final Pipe Dream with DuraLabel Pipe Markers

Directional pipe markers serve as essential wayfinding aids within industrial pipeline systems. These markers accurately lead workers through complex pipe networks. By understanding pipe markers and mastering their application process, workers boost safety, efficiency, and regulatory compliance in the workplace.

With the right tools it can make all the difference when it comes to making reliable pipe markers. That’s why it’s important to find a high-quality printer designed to simplify the creation of pipe marker labels. The DuraLabel Toro Max Industrial Label Printer is the perfect, all-in-one industrial printer for all of your pipe marking needs. Through continued education and training, you can ensure these printed signs protect your workers and the environment.

One way to learn more about pipe marking is with DuraLabel’s free Pipe Marking Instant Action Guide. This guide can help with being compliant with OSHA/ANSI standards, hazards that may be flowing through pipes and staying up to date with industry-specific standards. Get help crafting a system that will provide the safety communication you need. Call 1-888-695-5670 and one of our experts will guide you through the process.

Read Next:

Benefits of Pipe Marking

Water Treatment Pipe Marking Benefits

RELATED RESOURCES

Pipe Marking & Pipe Corrosion Control

The Silver Eagle Refinery explosion released a tidal wave of broken glass. Homes were pushed off their ...

Read

Facility Safety and Compliance: Utilizing the Right Pipe Markers

Imagine walking through a large facility filled with pipes running in every direction. These pipes carry ...

Read

Pipe Marking: A Safety Tool Worth Examining

Simple tools like pipe marking can make a difference in efficiency for any facility. Workers, guests, and ...

Read.png)