Floor Marking for Safety & Productivity FAQ

Floor Marking for Workplace Safety and Efficiency

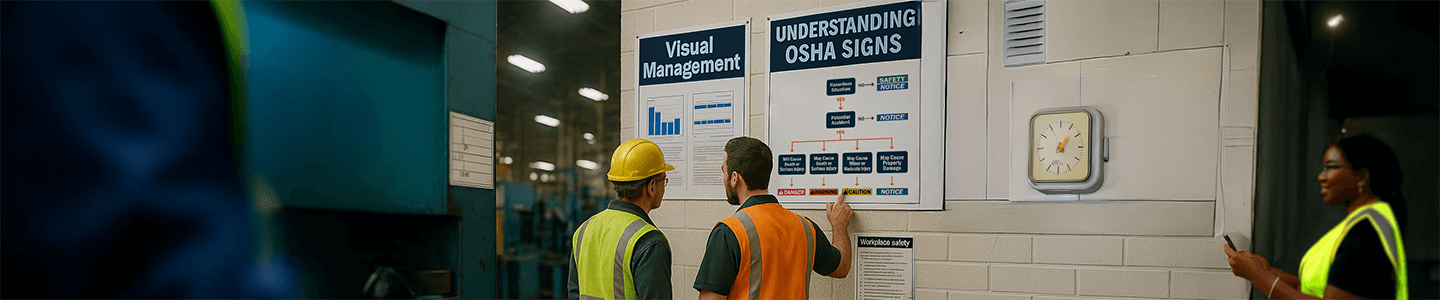

Floor marking is one of the simplest yet most effective ways to improve safety and efficiency in the workplace. By clearly identifying walkways, hazard zones, and storage areas, floor markings help employees stay organized and alert to potential dangers. OSHA and ANSI standards provide clear guidelines for color coding and placement, making compliance a straightforward part of your safety strategy.

Topics Covered:

This section breaks down the key benefits and requirements of floor marking.

- Compliance Requirements: Understand OSHA and ANSI guidelines for color coding and marking placement.

- Safety Applications: Explore how floor markings reduce accidents by highlighting hazards and directing traffic.

- Lean and 5S Integration: Learn how floor marking supports workplace organization and streamlines processes.

Use these resources to strengthen your floor marking program and enhance workplace safety and productivity.

Floor Marking for Safety & Productivity Frequently Asked Questions

- How can floor marking systems contribute to a more organized and efficient workspace?

- How does visual communication, like signage and labeling, impact facility workflow?

- What are the benefits of implementing Lean manufacturing principles in facility operations?

- What role does employee training play in enhancing facility efficiency?

- What strategies can improve operational efficiency within an industrial facility?

- How can facilities reduce winter slip and visibility risks?

Explore our extensive FAQ library to get insights on industrial labeling, workplace safety, and compliance. Find solutions and best practices for maintaining a safe and efficient work environment.

Related Resources

Visual Factory Tools FAQ

Visual Factory Tool Resources to Boost Safety and Streamline Workflows A visual factory uses signs, labels, ...

Read

Pipe Marking Standards FAQ

Pipe Marking Standards for Safety and Compliance This section covers the standards for labeling pipes under ...

Read

Food & Beverage Industry Labeling FAQ

Labeling Requirements for Food and Beverage Facilities Labeling in food and beverage environments must meet ...

Read.png)