Quick Navigation

Articles

- In depth looks at safety challenges you face.

- Industry standard practices and how to implement

- A look at how to improve day to day processes

Featured Articles

A Comprehensive Guide to Choosing the Right Industrial Label Printer

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the ...

Read Full Article2023 Top OSHA Violations

Read Full Article

Top 10: OSHA Violations for 2022: Stay Compliant & Safe

Read Full Article

Safety You Can See, Successful Construction Communication

Read Full Article

Is Your Workplace Evacuation Plan Afraid of the Dark? Add Wayfinding

Read Full Article

Can You Take the Heat? 5 Tips to Reduce Heat Exposure

Millions of U.S. workers are exposed to heat elements in their workplace each year. Hazardous heat exposure ...

Read Full ArticleWARNING: Stay Out of The Hospital, Wear Your PPE

Read Full Article

Watch Out: 3 Simple Tips to Prevent Brain Injuries

Read Full Article

Got a Need for Speed? Here Are 5 Ways to Increase Productivity Without Sacrificing Safety

Read Full Article

Mental Health is Worker Health: 6 Tips to Prevent Employee Burnout

Read Full Article

As a safety manager, leveraging your site safety committee effectively can transform your workplace ...

Safety Requirements for Solar: Ensure Compliance and Protect Workers

Solar installations are becoming common as renewable energy sources gain traction worldwide. However, like ...

Understanding the New OSHA Requirements for Safety Helmets

Occupational Safety and Health Administration (OSHA) regulations are constantly evolving to improve workplace ...

OSHA Cranks Up Heat Safety Standards

In compliance with the Small Business Regulatory Enforcement Fairness Act (SBREFA), OSHA assembled an SBAR ...

Tip from Fipps: Make Safety Fun

Traditional approaches to safety training, while effective, often struggle to maintain engagement and ...

Pulling Back the Curtain: A Look at DuraLabel’s Tough-Tested Process

When researching reliable safety products and solutions, consumers want something that is long-lasting even ...

Breaking Language Barriers: Key to Safer and More Inclusive Workplaces

From workplaces and public spaces to transportation hubs and construction sites, the presence of clear and ...

Wearable Technology: Enhancing Worker Safety in the Modern Workplace

Wearable technology is a transformative solution, offering real-time monitoring, communication, and support ...

10 Tips for Staying Current on Safety Regulations

Staying current with compliance standards is not only crucial but also a fundamental responsibility for ...

Boosting Workplace Efficiency Amid Labor Shortages: The Power of 5S

One of the most pressing challenges companies face is the shortage of skilled labor. As organizations strive ...

National Safety Month: Custom Signage to Combat Workplace Hazards

When we think about workplace accidents, it’s hard not to think about the most dramatic, worst-case scenarios ...

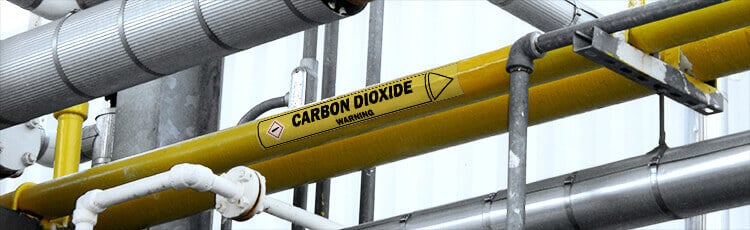

CO2 Cylinder Tanks and the Art of Labeling

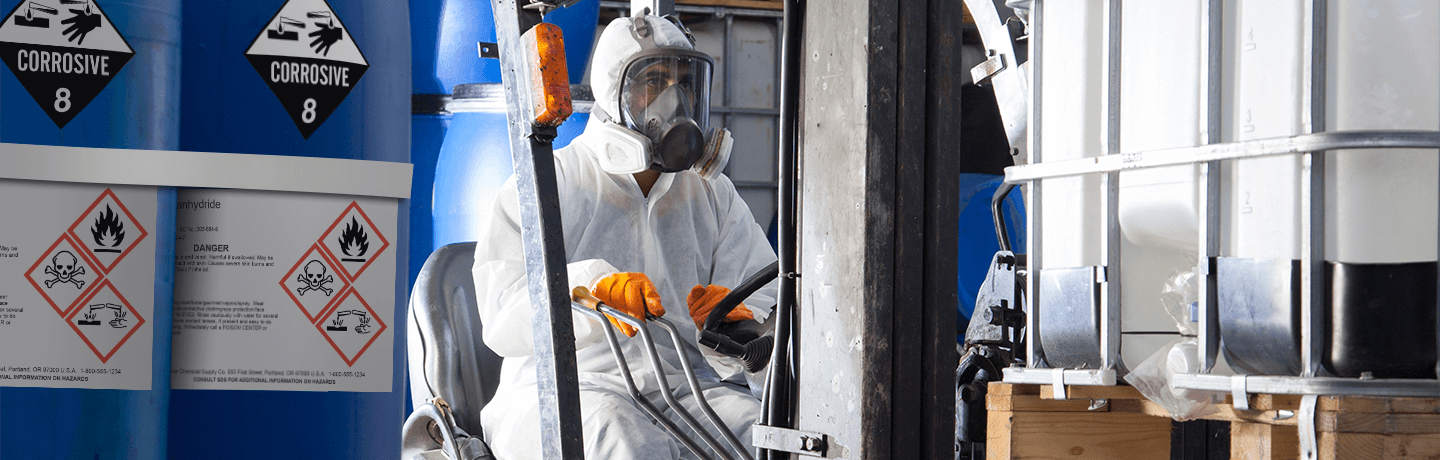

Dealing with dangerous substances is a major concern for any workplace. Whether it's chemicals that can burn ...

A Comprehensive Guide to Choosing the Right Industrial Label Printer

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the ...

Fight Pipe Marker UV Damage with Industrial Label Printers

Combating UV Damage to Pipe Markers with Industrial Label Printers Pipes serve as the glue to many sectors of ...

Tips From Fipps: Encouraging Safe Work Practices

It's important to note that workplace safety is not just about meeting compliance but approaching safety ...

Zone Out Injuries: Strategies to Ensure Safer Work Zones

Work zones are essential to maintaining and upgrading our roadways. Unfortunately, these zones can create ...

A Quick Guide to Floor Marking Products

In today's industrial workforce, workers must know how to navigate through many obstacles often including ...

Five Ways Floor Marking Can Solve Common Problems

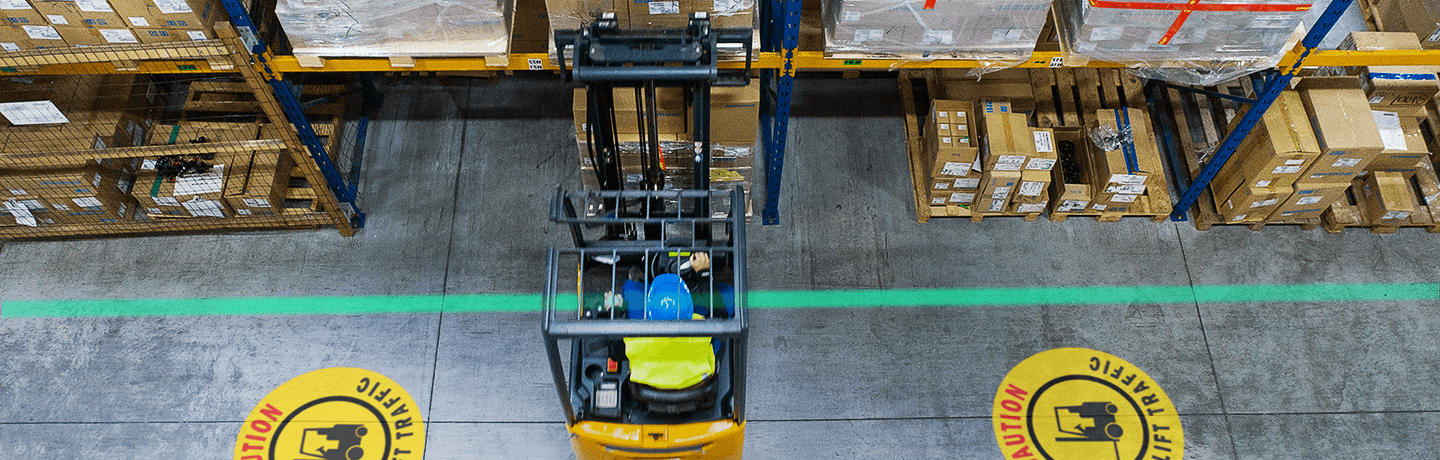

What Problems Does Floor Marking Address? Floor marking is the process of using tapes, paints, or other ...

Three Essential Tips to Prevent Workplace Head Injuries

Brain Injury Awareness Month Every year, the Brain Injury Association, the nation’s oldest and largest brain ...

What is Floor Marking?

Visual safety communication takes many forms in the workplace. Beyond just signs and labels, floor marking is ...

Safety is Your Right

Understanding Your Workplace Rights and Promoting a Safe Environment In the United States, federal law ...

How to Choose the Right Floor Marking Tape

Floor marking tape is designed to inform workers when they are approaching a safety hazard. OSHA requires ...

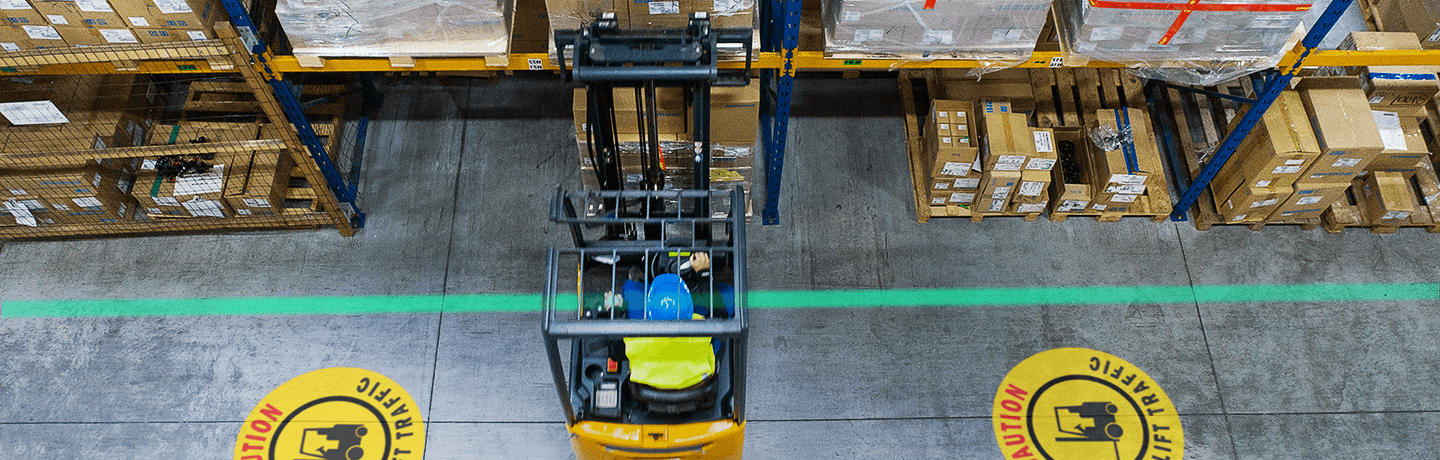

Upgrade Warehouse Traffic Safety with Floor Marking

Modern warehouses experience a wide variety of traffic ranging from forklifts and pedestrians to large ...

Tips for Choosing the Optimal Floor Marking Tape

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To ...

Tips from a Brewer for Effective Floor Marking

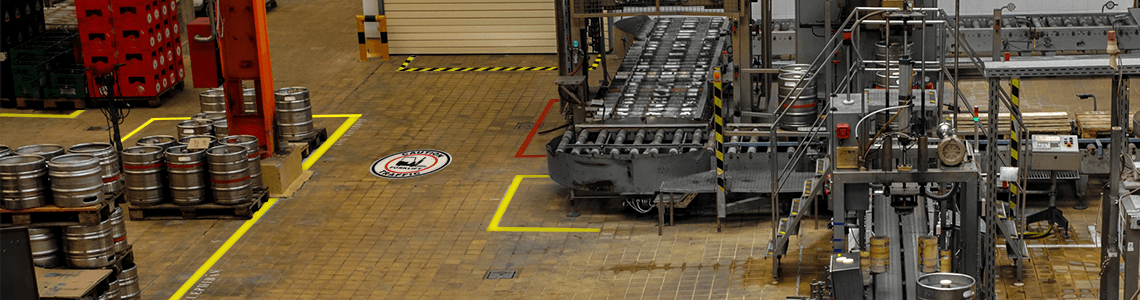

Hold My Beer: 5 Floor Marking Tips from a Brewery In the heart of the brewery, every step is important for ...

Maximize Safety on a Budget

Budget-Friendly Protection: Smart Tips to Maximize Safety Without Breaking the Bank In order to implement any ...

Chilled Signals

Safeguarding Workers with Strategic Signage as We Navigate the Winter Landscape As the temperatures continue ...

Tips from Fipps: Be Your Own Safety Superhero

Ensuring a safe and secure work environment is a shared responsibility that each one of us plays a crucial ...

Enhancing Safety in Medical Facilities with 5S

A Guide to Visual Communication Following 5S Best Practices Creating a robust visual communication system is ...

2023 Top OSHA Violations

Top 10: OSHA Violations for 2023: Stay Compliant & Safe In the realm of occupational safety, staying ...

Tips From Fipps: From Fear to Empowerment

From Fear to Empowerment: How OSHA's Free Consultation Transforms Workplace Safety In the realm of workplace ...

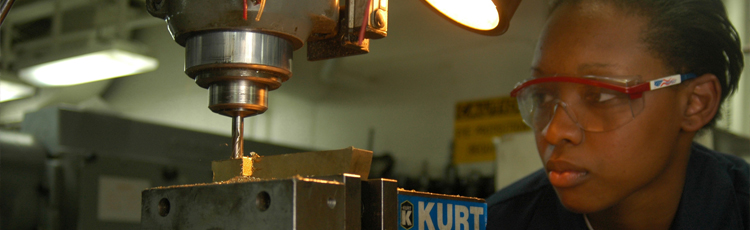

Women in the Safety Industry

Breaking Barriers: Women Shatter Stereotypes in Health and Safety The lack of gender diversity is an issue ...

Choosing the Ideal Field Printer for Your On-Site Printing Needs

In an industry that is often fast-paced, where the possibilities go beyond the traditional office setting, ...

Industrial Wayfinding 101: Navigating the Terrain of Industrial Spaces

In the sprawling landscapes of industrial facilities, warehouses, and manufacturing plants, effective ...

Tips From Fipps: It Pays to Be Safe, The Business Case for Workplace Safety

Workplace safety is not only crucial for protecting employees' well-being but also for the overall success of ...

Building a Safer Work Environment: 5 Powerful Benefits of Safety Training

There are 12,900 worker-related injuries every day, according to the National Safety Council, and this ...

Unlocking Success: 5 Essential Tips for Effective Training

Workplace injuries are common occurrences. There are 12,900 worker-related injuries every day, according to ...

Protect Your Ears: Strategies to Prevent Work-Related Hearing Loss

It is no secret that noise plays a factor in day-to-day industrial manufacturing. Unfortunately, it is also ...

Tip From Fipps: Safety Training is a Plan, Not an Event

Safety is an essential aspect of any workplace. To ensure the well-being of employees and comply with ...

Choosing the Right Industrial Label Printer for Your Business Needs

In the world of industrial labeling, one size certainly does not fit all. Different businesses and industries ...

Label Printer Systems for Challenging Outdoor Environments

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing ...

Maximizing Productivity: 4 Tips for Optimizing Field Printing Processes

The sounds of blaring horns and alarms fill your ears. Nothing is more insufferable or uninspiring than ...

Navigating GHS Labeling: How GHS Label Printers Simplify Compliance

In today's industrial landscape, workplace safety and chemical hazard communication are paramount. The ...

Meeting Industry Standards: Arc Flash Label Printing Requirements

A routine maintenance task is in progress, and as the technician attempts to tighten a loose connection on a ...

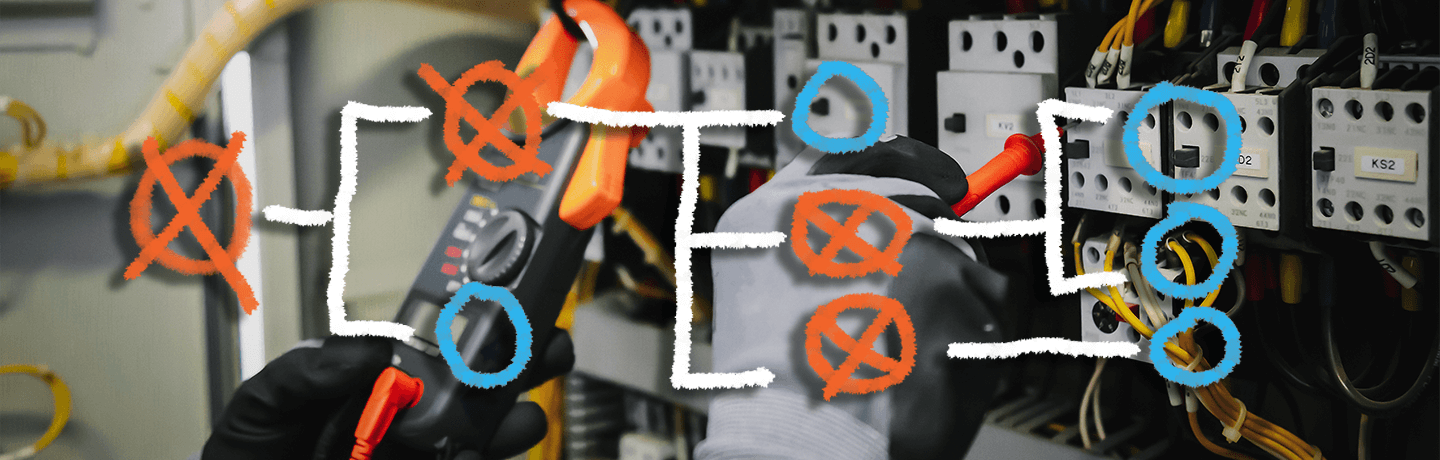

Halt Arc Flash Incidents - Improve Communication Using a Label Printer

Arc flashes are a dangerous electrical phenomenon that can occur in intense voltage areas and are more common ...

Creating Compliant OSHA Signs: Tips and Best Practices

Creating compliant OSHA safety signs is a crucial element in the overarching mission of fostering a safe and ...

9 Tips for Effective Safety Messaging to Prevent Common Injuries

Organizations are required under the OSHA General Duty clause to provide a working environment "free from ...

Shine a Light on Safety: LED Floor Marking Improves Wayfinding

Floor marking and signs in industrial environments are a cost-effective way to increase safety compliance, ...

We Are All in This Together: Building a Safety Culture with Management Buy-In

Creating a safe work environment requires more than just following rules and providing training. It ...

Prepare for the Worst: 5 Tips to be Ready for Disaster

Whether by force of nature or unfortunate accident, disasters can strike at any moment. In the workplace, ...

What Is Kanban?

In the face of declining sales and profits during the 1950s, Eiji Toyoda began looking for ways to improve ...

Top 10: OSHA Violations for 2022: Stay Compliant & Safe

The undisputed champion continues its streak with year 12 at the top of the list.The standard outlines when ...

Safety You Can See, Successful Construction Communication

1,008 construction workers were killed in workplace accidents in 2020, 21% of all fatal occupational ...

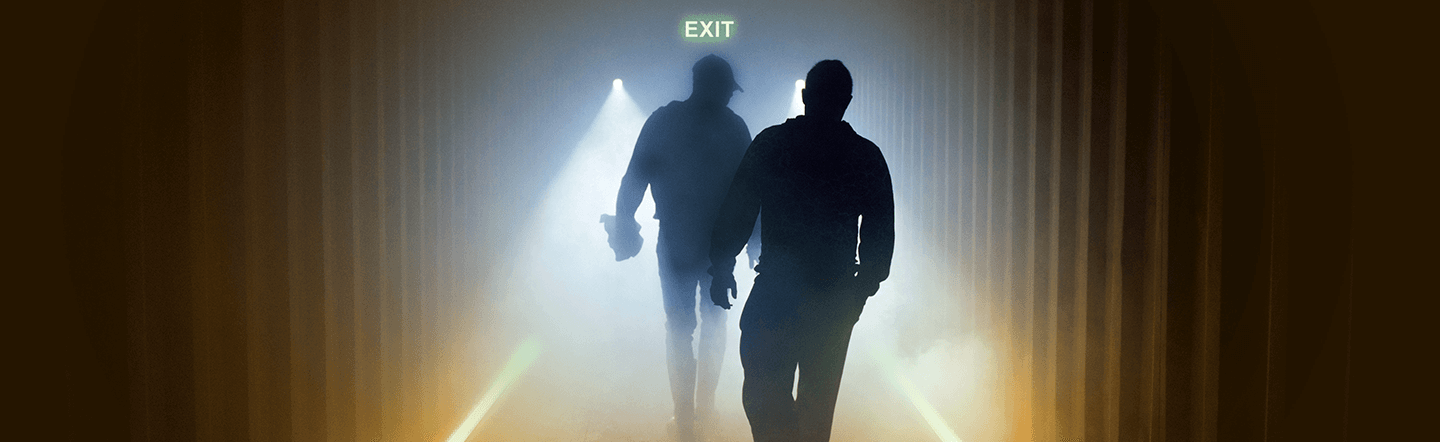

Is Your Workplace Evacuation Plan Afraid of the Dark? Add Wayfinding

Power outages have surpassed the 2013 U.S. average by 30% in the last two years, according to the Department ...

Can You Take the Heat? 5 Tips to Reduce Heat Exposure

Millions of U.S. workers are exposed to heat elements in their workplace each year. Hazardous heat exposure ...

WARNING: Stay Out of The Hospital, Wear Your PPE

Personal protective equipment (PPE) related violations accounted for three of the top 10 most frequent OSHA ...

Watch Out: 3 Simple Tips to Prevent Brain Injuries

According to the Brain Injury Association, each year 2.8 million people sustain a workplace-related brain ...

Got a Need for Speed? Here Are 5 Ways to Increase Productivity Without Sacrificing Safety

Safety is an essential element of any facility's success. The real challenge is how to maintain productivity ...

Next Steps to Safety: 5 OSHA Rule Changes for 2023

As the calendar rolls over to 2023, sites that resolve to make safety a priority will have some new rules and ...

Engage and Protect: Create a Safety Culture That Sticks

71% believe their employers are not following through on safety promises 64% report no active efforts to ...

Mental Health is Worker Health: 6 Tips to Prevent Employee Burnout

88% of workers experience some burnout, with 60% reporting high levels of burnout* One-fifth will miss six or ...

Educate and Protect Your People 5 Easy Ways to Prevent Burns

450,000 people suffer burn injuries each year . Burns account for 42% of all workplace injuries . 20% of ...

Hard Hat Requirements

OSHA/ANSI Hardhat Requirements 68,000 injuries in 2020 required an absence from work 1,000 workers killed ...

Don't Sacrifice Worker Safety: 4 Tips to Better Worker Engagement

One of the struggles of being in management is discovering new ways to engage employees in a way that ...

4 Tips to Enhance Loading Dock Safety

There are more than 4.2 million material movers in the U.S., most of which work in transportation and ...

Avoid Costly Mistakes When Shipping Hazardous Materials

Companies fail to meet basic hazardous materials shipping requirements every year. Recently, a Columbus ...

Guard Your Workers: 5 Easy Solutions for Machine Safety

Powerful machines have severe hazards. Improperly guarded machines each year cause: 18,000 amputations 800 ...

Five Easy Ways to Enhance Loading Dock Safety

Warehouses are busy work environments. Keep loading dock workers moving efficiently and safety using these ...

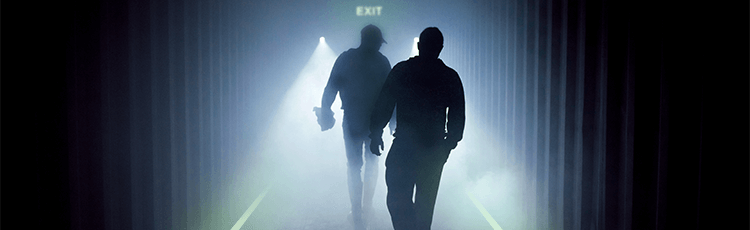

OSHA 1910 145 Warning Signs and Tags

No matter the industry, hazards are rampant in workplaces throughout the United States. Manufacturing ...

Logistics Tracking

Logistics involves managing the movement of resources. This not only includes products, but the movement and ...

Toxic Waste

What is toxic waste? Toxic waste may be defined as discarded material that may pose a substantial threat or ...

Chaku Chaku

Chaku chaku, literally meaning "load load," is a Japanese term for a single-piece manufacturing process based ...

Understanding OSHA's 1910 120 (HAZWOPER) Requirements

OSHA is not involved in regulating hazardous waste. However, they are concerned about the safety of workers ...

OSHA 1910 144 Color Identification

Standard Number: 1910.144 Safety color code for marking physical hazards. 1910.144(a) Color identification - ...

Continuous Improvement Ideas for the Workplace

Success in today's competitive market requires constant innovation and a vision focused on continuous ...

Top 10 Uses for DuraLabel Industrial Label Printers

Workplace safety is more important than ever before. With federal rules and regulations in place and always ...

Ways to Improve Construction Site Safety

The term "time is money" is quite literal in the construction industry. The constant pressure project ...

Planned Maintenance

Planned maintenance is a proactive approach to maintenance in which maintenance work is scheduled to take ...

Kaizen Benefits

Businesses continue to turn towards lean manufacturing tools to find ways to tighten their belts and remain ...

Best Practices for Airfield Vehicle Marking

The demand for air travel is on the rise which means more personnel navigating the airfield, increasing the ...

OSHA Sound Levels

What is noise? Is all noise bad? Where does noise come from? Vibrations detected by the human ear are called ...

Product Identification

Product identification is a broad category of labeling that includes functions such as product traceability, ...

OSHA Safety Management Plan

What is an OSHA Safety Plan? An OSHA Safety Plan is a written plan that describes the potential hazards in ...

International Fire Code

The International Fire Code (IFC) provides fire prevention and safety standards for existing buildings. It ...

Arc Flash in Mining

Very little can happen in mining without electricity. From drilling equipment and powered shovels to fixed ...

OSHA 29 CFR 1926

Construction is a high hazard industry, with unique situations and hazards, and it employs more than six ...

Water Treatment Pipe Marking Benefits

Water Treatment Pipe Marking Benefits Pipe marking is an essential part of any water treatment facility. ...

Six Sigma Principles that Align with 5S

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S ...

Improving Job Site Safety with an Industrial Label Printer

OSHA reports that nearly 6.5 million workers are employed at approximately 252,000 construction job sites in ...

Guidelines for OSHA's Fall Protection Standards & Compliance

Ineffective or missing fall protection has been OSHA's most-cited violation every year since 2011, and falls ...

Machine Guards and Amputation Hazards

One of the first facets of workplace safety to be regulated by OSHA in 1971 was operating or maintaining ...

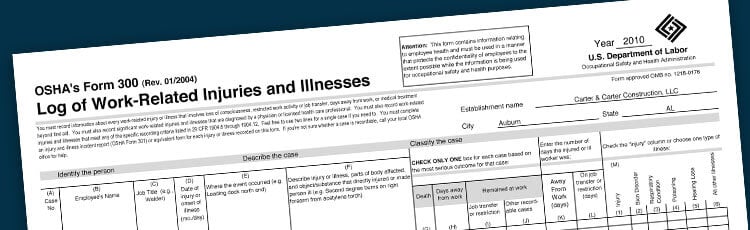

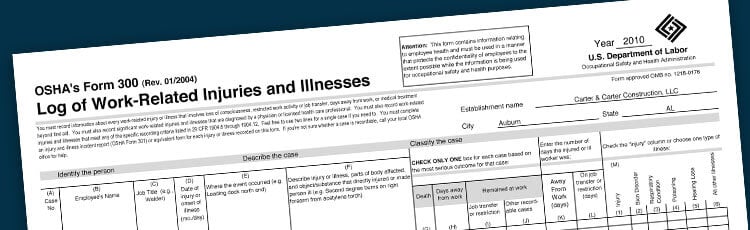

What is an OSHA 300 Log?and do I have to use one?

If your workplace has more than 10 employees at any time throughout the calendar year, and is non-exempt, ...

The Eight Steps to the QCDSM Process

QCDSM is a mouthful of an acronym. Once you learn its meaning and apply its principles to your business ...

Safety Risk Management

In our experience, those companies who place major significance on risk management are the most successful in ...

Optimizing Fault Tree Analysis with Industrial Label Printers

In this day and age, businesses the world over are placing a premium on dependability. With so many ...

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA's Standard for Electrical Safety in the Workplace, outlines specific ...

Obeya in the Workplace: An Overview

At its core, "obeya" (Japanese for "big room" or "great room") is a lean manufacturing tool, in which a ...

Boosting Workplace Efficiency Amid Labor Shortages: The Power of 5S

One of the most pressing challenges companies face is the shortage of skilled labor. As organizations strive ...

Tips for Choosing the Optimal Floor Marking Tape

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To ...

Enhancing Safety in Medical Facilities with 5S

A Guide to Visual Communication Following 5S Best Practices Creating a robust visual communication system is ...

What Is Kanban?

In the face of declining sales and profits during the 1950s, Eiji Toyoda began looking for ways to improve ...

Continuous Improvement Ideas for the Workplace

Success in today's competitive market requires constant innovation and a vision focused on continuous ...

Top 10 Uses for DuraLabel Industrial Label Printers

Workplace safety is more important than ever before. With federal rules and regulations in place and always ...

Six Sigma Principles that Align with 5S

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S ...

Lean Logistics Techniques

Any successful logistics system needs to provide the required materials where and when they are needed. Lean ...

Creating a Visual Factory with the 5S System

The term "visual factory" refers to an approach to lean manufacturing processes based on visual information ...

Warehouse Safety and Strategy With the 5S System

Implementing the5S system in your warehouse will create a leaner, more efficient workflow. But the rewards ...

1910 133 Eye And Face Protection

The Center for Disease Control and Prevention reports that each day 2,000 workers have a work-related eye ...

Lean Facility

Creating a Lean Facility The global market places significant pressure on businesses and other organizations ...

Lean Manufacturing Process

What is the Lean Manufacturing Process? The lean manufacturing process is a method for creating a more ...

OSHA Floor Marking Guide

Modern workplaces, however safe they may be, are fraught with hazards. Forklifts, energized equipment, ...

Performance Improvement Plan

Performance is the level of achievement reached under defined conditions. Performance improvement means ...

Getting Started with 5S

Staying on top of operational efficiency is an ongoing challenge. The lean 5S methodology is a powerful ...

Advantages of Lean Manufacturing

Lean Manufacturing Advantages Womack and Jones, in their book Lean Thinking, define lean manufacturing as "a ...

Continuous Improvement

What is Continuous Improvement? Continuous improvement is a philosophy of looking to improve products and ...

Quality Circles

The quality circle originated in Japan in the early 1960's. The objective was to give the responsibility for ...

The Organizational Development Process

To understand the organizational development process, we first need to know what organizational development ...

5S Methods Enhance Green Manufacturing

Manufacturing industries play a tug-of-war between the public and private sectors, each demanding the ...

Process Cycle Efficiency (PCE)

The Process Cycle Efficiency, sometimes referred to as the "Value Added Ratio," is a measurement of the ...

Quick Response Codes and Kanban

Quick Response codes, commonly known as QR codes, are two-dimensional barcodes that can be scanned and ...

Asset Management Benefits

Asset management is a system that helps you track your property and maximize the return on those assets, ...

Visual Workplace and Lean Manufacturing

When it comes to workplace improvement, it is almost second nature to think of lean manufacturing tools like ...

Periodic Inventory System

What is a Periodic Inventory System? A periodic inventory system is an accounting method in which the cost of ...

Lean Healthcare: Focusing on Quality and Safety

Lean Healthcare Quality and Safety Healthcare professionals have a long history of caring for their patients ...

Kaizen Getting Started

There is more to implementing Kaizen than we can include on a single web page. However, the following serves ...

What Is Lean Manufacturing

Lean is an efficient approach to running a process, business or organization to minimize waste, lower lead ...

FOCUS PDCA

FOCUS PDCA is a management method, developed in the healthcare industry, used to improve processes. Created ...

Tools for 5S Lean Manufacturing

The5S Systemis a lean manufacturing tool that helps to clean and organize the workplace, as well as improve ...

Lean Canvas

Compared to writing a business plan, which can take several weeks or months, you can outline multiple ...

Lean on Maintenance

What is Lean Maintenance? Lean manufacturing is arguably the single greatest advance in plant efficiency ...

Cross-Docking

What is Cross-Docking? At its most basic, cross-docking establishes a speedy, efficient system for unloading ...

Quick Response Manufacturing

If you are familiar with lean manufacturing principles, you know that lean manufacturing is about eliminating ...

Reinforce Safety in Cleanrooms with Floor Tape and More

The typical construction costs for building an ISO 8 to ISO 7 cleanroom can range from $250 to $1,500 per ...

Lean Tools

Five of the Most Helpful Lean Tools Lean manufacturing uses many lean tools to improve production and ...

10 Safety Tips for Oil and Gas Industry Workers

Workers in the oil and gas extraction industry continue to be one of the highest at risk of injuries and ...

What Is Kaizen?

Kaizen originated in Japan during the early 1950s and comes from two words: Kai (improvement) and Zen (good). ...

5S Examples in Action: The Good and the Bad

The 5S system is a powerful lean manufacturing tool with the potential to improve productivity and ...

Quality Control In Manufacturing

In manufacturing, quality control is a process that ensures customers receive products free from defects and ...

Inventory Planning

What is Inventory? The word "inventory" can have a number of definitions. In this article, we'll be talking ...

Linking Lean and Visuals

The visual workplace and lean are two distinct yet complementary tools that can improve work processes, make ...

Kanban Benefits

Kanban Provides a Number of Benefits. Kanban was developed as a method for controlling the flow of materials ...

Six Sigma Methodology

As the name implies, a Lean Six Sigma methodology combines the principles of lean manufacturing ("Lean") with ...

Process Map

Why Map a Process? Maps and flowcharts help make work visible. Increased visibility improves communication ...

Supply Chain Integration

Supply chain integration is the cooperation of buyers and sellers, with the goal that all parties benefit ...

Lean Manufacturing Principles

The Principles of Lean Manufacturing To gain a competitive edge, many companies have adopted lean ...

A Quick Guide to Floor Marking Products

In today's industrial workforce, workers must know how to navigate through many obstacles often including ...

Five Ways Floor Marking Can Solve Common Problems

What Problems Does Floor Marking Address? Floor marking is the process of using tapes, paints, or other ...

What is Floor Marking?

Visual safety communication takes many forms in the workplace. Beyond just signs and labels, floor marking is ...

How to Choose the Right Floor Marking Tape

Floor marking tape is designed to inform workers when they are approaching a safety hazard. OSHA requires ...

Upgrade Warehouse Traffic Safety with Floor Marking

Modern warehouses experience a wide variety of traffic ranging from forklifts and pedestrians to large ...

Tips for Choosing the Optimal Floor Marking Tape

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To ...

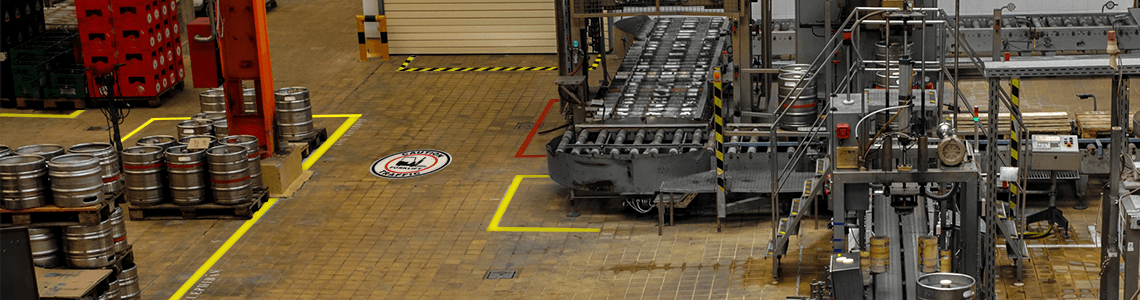

Tips from a Brewer for Effective Floor Marking

Hold My Beer: 5 Floor Marking Tips from a Brewery In the heart of the brewery, every step is important for ...

Industrial Wayfinding 101: Navigating the Terrain of Industrial Spaces

In the sprawling landscapes of industrial facilities, warehouses, and manufacturing plants, effective ...

Label Printer Systems for Challenging Outdoor Environments

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing ...

Shine a Light on Safety: LED Floor Marking Improves Wayfinding

Floor marking and signs in industrial environments are a cost-effective way to increase safety compliance, ...

Prepare for the Worst: 5 Tips to be Ready for Disaster

Whether by force of nature or unfortunate accident, disasters can strike at any moment. In the workplace, ...

Is Your Workplace Evacuation Plan Afraid of the Dark? Add Wayfinding

Power outages have surpassed the 2013 U.S. average by 30% in the last two years, according to the Department ...

5S Floor Marking

At its most fundamental level, 5S is about eliminating waste and getting a facility cleaned up and organized. ...

OSHA Floor Marking Guide

Modern workplaces, however safe they may be, are fraught with hazards. Forklifts, energized equipment, ...

Industrial Floor Tape vs. Floor Paint

Like the VCR or the ham radio, floor marking paint must now compete with a modern evolution of its function: ...

Types of Floor Marking

As workplaces grow increasingly sophisticated, it's imperative that employers keep workers safe, increase ...

Electrical Panel Compliance with Floor Marking

Electrical panels are an integral part of large and small facilities throughout the United States. The panels ...

Five Essential Forklift Safety Tips

Forklifts play an essential role in warehouses, retail outlets, and other businesses throughout the United ...

Floor Marking for Fire Extinguishers

Can employees and visitors easily locate reception areas, restrooms, and most importantly, emergency and fire ...

Floor Signs

When employers imagine floor marking, most think of aisle markers, pathway designations, and hazard stripes. ...

Reinforce Safety in Cleanrooms with Floor Tape and More

The typical construction costs for building an ISO 8 to ISO 7 cleanroom can range from $250 to $1,500 per ...

Floor Marking for Forklift Safety

Roughly 20,000 American workers are seriously injured in workplace accidents involving forklifts each year, ...

Floor Marking 101

Companies around the world, from major manufacturers down to your local grocery store, all share a common ...

Improving Job Site Safety with an Industrial Label Printer

OSHA reports that nearly 6.5 million workers are employed at approximately 252,000 construction job sites in ...

Parts of an SDS

Under the international standard called the Globally Harmonized System, or GHS, details about a chemical or ...

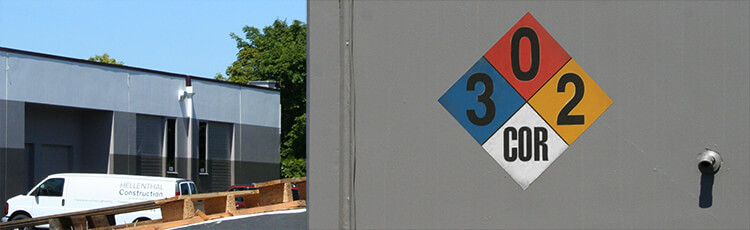

NFPA 704 vs HazCom 2012

A variety of labeling standards and classification systems are available for managing chemical safety. This ...

Hazardous Materials Identification System (HMIS) and OSHA Signs

Decoding HMIS and OSHA Signs: Creating Safety in Hazardous Environments In hazardous environments, ...

ANSI Cutting Standard

ANSI Cutting Standard The American National Standards Institute (ANSI) has updated its hand protection ...

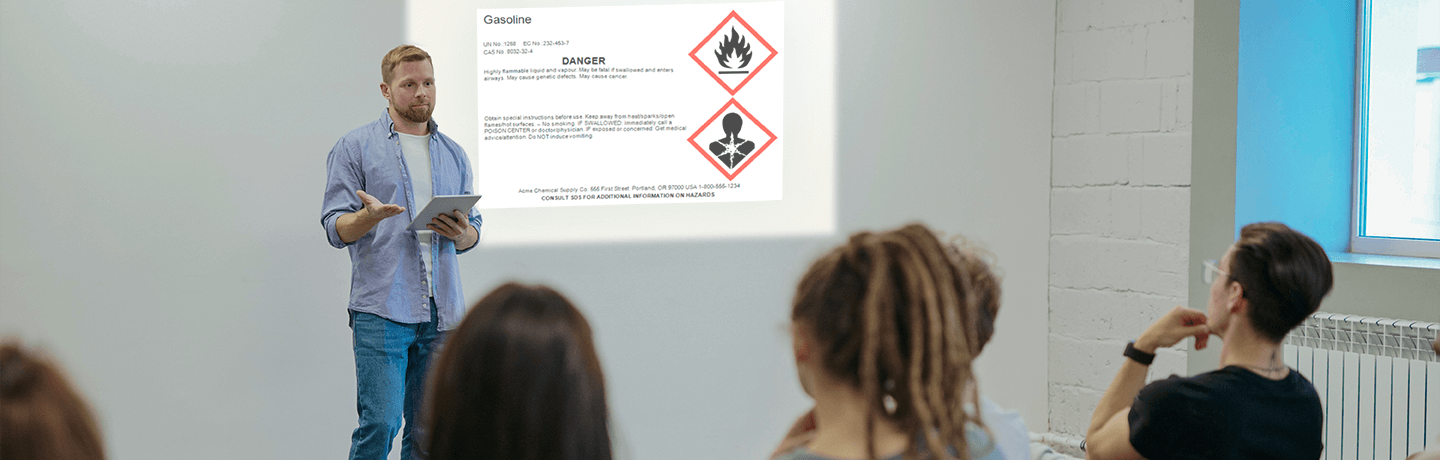

HazCom Training

OSHA's HazCom rules, sometimes called the Hazard Communication Standard or HazCom 2012, cover requirements ...

Red Diamonds on HazCom 2012 Labels

Six elements of information must be present on the typical HazCom 2012 chemical label, as listed in OSHA's ...

Common Questions about Chemical Laboratory Safety

More than 500,000 U.S. workers are exposed to all kinds of chemicals while working in laboratories. From ...

Understanding the SDS

Chemical safety can be a massive puzzle, with a variety of interconnected elements: inventory lists, storage ...

OSHA Requirements and Compliance

The Occupational Safety & Health Administration (OSHA) is dedicated to ensuring the safety and well-being ...

REACH Training

REACH is an acronym for Registration, Evaluation, Authorization and restriction of Chemicals. REACH is a ...

NFPA 704 Hazmat Diamond

NFPA 704 is titled "Identification of the Hazards of Materials for Emergency Response." NFPA 704 defines a ...

Brewery Safety: Common Violations and How to Stay Safe

Beer has never been a bigger business in the United States than it is today. Roughly 4,000 U.S. breweries ...

Lab Safety Labels

Permanent Container Safety Labels OSHA requires employers to ensure that no worker uses, stores, or allows ...

What is HAZOP? HAZOP Analysis and Industrial Label Printer Insights

Workplace safety should always be at the forefront of your mind. Many recommendations exist on how to go ...

ANSI Z87.1 Eye Safety & Eye Protection Glasses

Workers in nearly every industry can benefit from eye protection. Eye safety should be a top priority to ...

Arc Flash Printers: An Overview

Electrical hazard violations, including arc flash accidents, were the tenth most common OSHA citation in ...

Hazardous Waste Symbols

Symbols and pictograms are the fastest, most efficient and reliable way to communicate warnings. People ...

From MSDS to SDS

OSHA's HazCom 2012 rules require companies to have a Safety Data Sheet (SDS) for every hazardous chemical in ...

Understanding the New OSHA Requirements for Safety Helmets

Occupational Safety and Health Administration (OSHA) regulations are constantly evolving to improve workplace ...

Fight Pipe Marker UV Damage with Industrial Label Printers

Combating UV Damage to Pipe Markers with Industrial Label Printers Pipes serve as the glue to many sectors of ...

Three Essential Tips to Prevent Workplace Head Injuries

Brain Injury Awareness Month Every year, the Brain Injury Association, the nation’s oldest and largest brain ...

What is Floor Marking?

Visual safety communication takes many forms in the workplace. Beyond just signs and labels, floor marking is ...

Safety is Your Right

Understanding Your Workplace Rights and Promoting a Safe Environment In the United States, federal law ...

How to Choose the Right Floor Marking Tape

Floor marking tape is designed to inform workers when they are approaching a safety hazard. OSHA requires ...

2023 Top OSHA Violations

Top 10: OSHA Violations for 2023: Stay Compliant & Safe In the realm of occupational safety, staying ...

Top 10: OSHA Violations for 2022: Stay Compliant & Safe

The undisputed champion continues its streak with year 12 at the top of the list.The standard outlines when ...

Next Steps to Safety: 5 OSHA Rule Changes for 2023

As the calendar rolls over to 2023, sites that resolve to make safety a priority will have some new rules and ...

OSHA 1910 145 Warning Signs and Tags

No matter the industry, hazards are rampant in workplaces throughout the United States. Manufacturing ...

OSHA 1910 144 Color Identification

Standard Number: 1910.144 Safety color code for marking physical hazards. 1910.144(a) Color identification - ...

OSHA Sound Levels

What is noise? Is all noise bad? Where does noise come from? Vibrations detected by the human ear are called ...

OSHA Safety Management Plan

What is an OSHA Safety Plan? An OSHA Safety Plan is a written plan that describes the potential hazards in ...

OSHA 29 CFR 1926

Construction is a high hazard industry, with unique situations and hazards, and it employs more than six ...

Guidelines for OSHA's Fall Protection Standards & Compliance

Ineffective or missing fall protection has been OSHA's most-cited violation every year since 2011, and falls ...

What is an OSHA 300 Log?and do I have to use one?

If your workplace has more than 10 employees at any time throughout the calendar year, and is non-exempt, ...

OSHA Floor Marking Guide

Modern workplaces, however safe they may be, are fraught with hazards. Forklifts, energized equipment, ...

Confined Spaces: How to Satisfy OSHA Compliance

While you may think of any small area as a confined space, the OSHA definition is slightly different. It is ...

What is OSHA Compliance?

Dangerous working conditions nationwide sparked the creation of the Occupational Safety and Health Act (OSH ...

OSHA General Duty Clause

What is the OSHA General Duty Clause? OSHA's General Duty Clause, in its entirety, reads: "Each employer ...

Five Ways to Meet OSHA Requirements for Safety Signage

Every day, American workers service high-powered equipment, build and fix roads, and manufacture the goods we ...

OSHA Requirements and Compliance

The Occupational Safety & Health Administration (OSHA) is dedicated to ensuring the safety and well-being ...

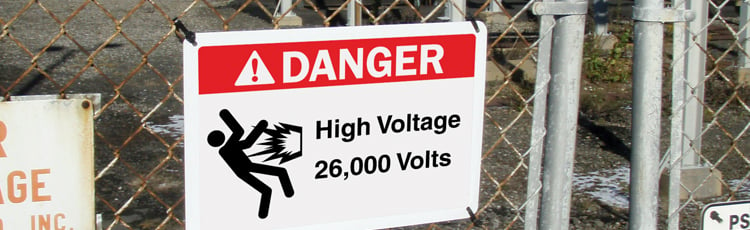

4 Electrical Hazards of the Power Industry: OSHA Signs for Safety

OSHA Signs to Increase Safety in the Electric Power Industry In the high-risk environment of the electric ...

Ignite Safety: Mastering OSHA Fire Prevention Compliance

In any workplace, fire safety is not just a box to tick—it is about keeping your team out of harm's way. The ...

GHS Label Information

Appendix C to the 2012 (OSHA 1910.1200) Hazard Communication Standard (HCS) specifies the mandatory ...

Fire Readiness Essentials for Any Workplace

Fire safety is a top concern for businesses of all sizes. The U.S. Fire Administration (USFA) reported that ...

OSHA Construction Safety

What is OSHA Construction Safety? When it comes to safety, the construction industry has a higher fatality ...

What Is OSHA 10? | OSHA 10 Certification |

The term OSHA 10 refers to the OSHA Ten Hour Training that is part of the OSHA Outreach Training Program. The ...

Strengthening Arc Flash Hazard Analysis with OSHA Signs

Conducting an arc flash hazard study is the cornerstone for worker safety when working with live equipment ...

OSHA & ANSI Hard Hat Requirements

Around construction sites, hard hats are the best way to protect yourself from permanent, life-changing ...

OSHA and ANSI Safety Colors

What's the first thing you think of when you imagine a red sign? The odds are good that you picture an ...

Pipe Makers & Pipe Labels | Piple Marking Labels

Workplaces are safer than ever, but challenges remain: In 2014, nearly three million nonfatal workplace ...

OSHA Confined Space

OSHA Confined Space Safety OSHA's regulation 29 CFR 1910.146 covers "permit-required confined spaces." This ...

OSHA Rules for Hazardous Chemicals

When dealing with hazardous chemicals, safety is key. However, the steps necessary to keep workers safe will ...

Does Improved Safety Mean Fewer OSHA Violations?

Headlines show that fatalities,injuries,and illnesses in the workplace are on a downward trend. Statistics ...

OSHA Severe Violator Enhancement Program SVEP

Teachers, cops, FBI, even the USDA are authorized to dole out punishment in an attempt to induce desired ...

OSHA Hearing Protection Requirements

The stats don't lie: According to the National Institute for Occupational Safety and Health, 22 million ...

What is HAZOP? HAZOP Analysis and Industrial Label Printer Insights

Workplace safety should always be at the forefront of your mind. Many recommendations exist on how to go ...

OSHA 29 CFR 1910

The Occupational Safety and Health Administration (OSHA) is a branch of the United States Department of Labor ...

How to Pass an OSHA Inspection

Under the Occupational Safety and Health Act of 1970, OSHA is authorized to conduct workplace inspections to ...

OSHA and NFPA 70E

When workers performing maintenance or repairs on energized electrical equipment, they could be exposed to an ...

OSHA Citations

OSHA citations are routinely given to companies throughout the United States. Organizations large and small ...

Prevent Arc Flash with LO/TO and OSHA Signs

The Role of LO/TO and OSHA Signs in Safeguarding Against Arc Flash In the realm of electrical safety, the ...

Avoiding OSHA Fines: Machine Guarding

OSHA produces an annual list of the Top 10 Most Frequently Cited Standards and year after year, machine ...

OSHA 1926 Requirements

Because it is a high hazard industry, with unique situations and hazards, and employing more than six million ...

Free OSHA GHS Training

OSHA GHS Proposal OSHA mandated changes to its hazard communication standard (HCS), and aligned itself with ...

Fire Exits

If your building starts filling with smoke, how will you quickly get out? Do you know where the closest exits ...

Scaffolding Fall Hazards

In November 2013, a Massachusetts roofer fell to his death while working on a condominium. An OSHA ...

OSHA Construction Site Compliance

OSHA construction compliance is a key element for maintaining a safe jobsite. According to OSHA, nearly 6.5 ...

How to Improve Your Facility's Safety with Compliance Labeling

Before beginning work, it's crucial to evaluate your facility for safety hazards. Consistent and effective ...

Pulling Back the Curtain: A Look at DuraLabel’s Tough-Tested Process

When researching reliable safety products and solutions, consumers want something that is long-lasting even ...

Fight Pipe Marker UV Damage with Industrial Label Printers

Combating UV Damage to Pipe Markers with Industrial Label Printers Pipes serve as the glue to many sectors of ...

Water Treatment Pipe Marking Benefits

Water Treatment Pipe Marking Benefits Pipe marking is an essential part of any water treatment facility. ...

How to Meet IIAR Standards for Ammonia Pipe Marking

For safe operations and maintenance, its important employees know what's inside the pipes they're working ...

BS 1710 British Standard Pipe Marking

British Standard 1710 (BS 1710) provides a robust framework that fulfills the pipe marking requirements set ...

ASME A13.1 | Pipe Marking Guide | ANSI Pipe Labeling |

Pipe marking quickly communicates essential information to everyone in a facility, improving overall ...

Avoiding Hazards in the Food Processing Industry with a Label Printer

Journalist and activist Upton Sinclair revealed the horrors of the food processing and manufacturing industry ...

Benefits of Pipe Marking

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe ...

Pipe Marking Basics: Pipe Labeling Standards for Safety and Efficiency

Pipes can put people and facilities in danger if no one knows what's flowing through them. Pipe labels help ...

How to Get Started with Pipe Marking & Labeling

Pipe marking quickly communicates information about a pipe and its contents, improving overall workplace ...

UK Pipe Marking: Regulations vs. Standards

UK Pipe Marking When it comes to pipe marking in the United Kingdom (UK), there are two commonly cited ...

Ammonia Refrigeration System Fundamentals

Artificial cooling systems keep industry running, and many of these systems use anhydrous ammonia as a ...

What is HAZOP? HAZOP Analysis and Industrial Label Printer Insights

Workplace safety should always be at the forefront of your mind. Many recommendations exist on how to go ...

Halt Arc Flash Incidents - Improve Communication Using a Label Printer

Arc flashes are a dangerous electrical phenomenon that can occur in intense voltage areas and are more common ...

OSHA 1910 144 Color Identification

Standard Number: 1910.144 Safety color code for marking physical hazards. 1910.144(a) Color identification - ...

Top 10 Uses for DuraLabel Industrial Label Printers

Workplace safety is more important than ever before. With federal rules and regulations in place and always ...

Arc Flash in Mining

Very little can happen in mining without electricity. From drilling equipment and powered shovels to fixed ...

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA's Standard for Electrical Safety in the Workplace, outlines specific ...

Arc Flash Labels

When electrical equipment must be maintained or repaired while energized, an arc flash hazard may be present. ...

Arc Flash PPE

Personal Protective Equipment (PPE) is the last line of defense against injuries. When it comes to arc flash, ...

NEMA Standards

The National Electrical Manufacturers Association (NEMA) is an industry association for two types of ...

Importance of Lockout Tagout Training to Reduce Arc Flash

Machines inevitably break down and need to be serviced. It's not enough to just "shut them off" and make ...

Printing Electrical Safety Signs with a Thermal Transfer Printer

Electrical safety is a major problem in modern workplaces. Each year, OSHA produces a list of their ten most ...

Reducing Arc Blast with Effective Short Circuit Analysis

Understanding Arc Blast: What is a Short Circuit? A short circuit is the flow of current through an ...

What Is An Arc Flash

An arc flash is an explosive burst of heat and light, caused by a sudden, uncontrolled electrical arc (or ...

Electrical Panel Compliance with Floor Marking

Electrical panels are an integral part of large and small facilities throughout the United States. The panels ...

Arc Flash Accident Videos

With YouTube and other video-sharing websites, an unimaginable number of videos on just about any subject can ...

Arc Flash Safety | Arc Flash Training Requirements

In the modern workplace, electricity is a driving force. Motors, ovens, presses, and mills can all be powered ...

Arc Flash Boundary

NFPA 70E is the major industrial standard for safe electrical work in the United States. It defines three ...

Strengthening Arc Flash Hazard Analysis with OSHA Signs

Conducting an arc flash hazard study is the cornerstone for worker safety when working with live equipment ...

Using a Label Printer for Safety Hazard Signs & Workplace Safety Signs

Safety labels and signs are an essential part of any workplace safety program, and utilizing a high-quality ...

Fault Current Calculations

A fault current is an unintended, uncontrolled, high current flow through an electrical system. Fault ...

OSHA and NFPA 70E

When workers performing maintenance or repairs on energized electrical equipment, they could be exposed to an ...

Prevent Arc Flash with LO/TO and OSHA Signs

The Role of LO/TO and OSHA Signs in Safeguarding Against Arc Flash In the realm of electrical safety, the ...

Arc Flash Printers: An Overview

Electrical hazard violations, including arc flash accidents, were the tenth most common OSHA citation in ...

Incident Energy

Incident energy is a measurement of energy, usually heat, striking a surface. If you were sitting near a ...

Arc Flash Accident Reports

An arc flash is dangerous and has the potential for causing serious injuries. It typically occurs suddenly ...

Support

Project Consultation

Get help on a project and recommendations for solutions. Our signage experts can guide you to your goal, just start with a call.

Product Support

Get help with DuraLabel products and support with using software. Making labels, troubleshooting, or product recommendations.

.png)